Pros and Cons of 3D Printing

The Pros and Cons of 3D printing Explore the advantages and disadvantages of 3D printing. Learn more now!

Introduction Pros and Cons of 3D Printing

3D printing is an additive manufacturing process rapidly growing in the economy's industrial, commercial, and hobbyist segments. The industry's popularity is due to the ground-breaking benefits of innovative technology. The global 3D printing industry is growing rapidly and is projected to grow from $18.3 billion in 2022 to over $83 billion by 2029.

3D printing has broken into every major industry. The applications are most noticeable in the aerospace, automotive, medical, and dental sectors. The education, construction, robotic, fashion, and food industries also integrate 3D printing into their businesses.

The onset of Industry 4.0 in helping fuel the rapid rise in the 3D printing industry, the centerpiece of additive manufacturing. Industry 4.0 integrates new technologies, including cloud computing, the Internet of Things (IoT), additive manufacturing, artificial intelligence (AI), and data analytics, into their production and business operations. These integrated technologies will transform the way companies produce products and services.

What Are the Pros of 3D Printing?

The advantages of the fast-growing 3D printing industry are numerous. The benefits include the following:

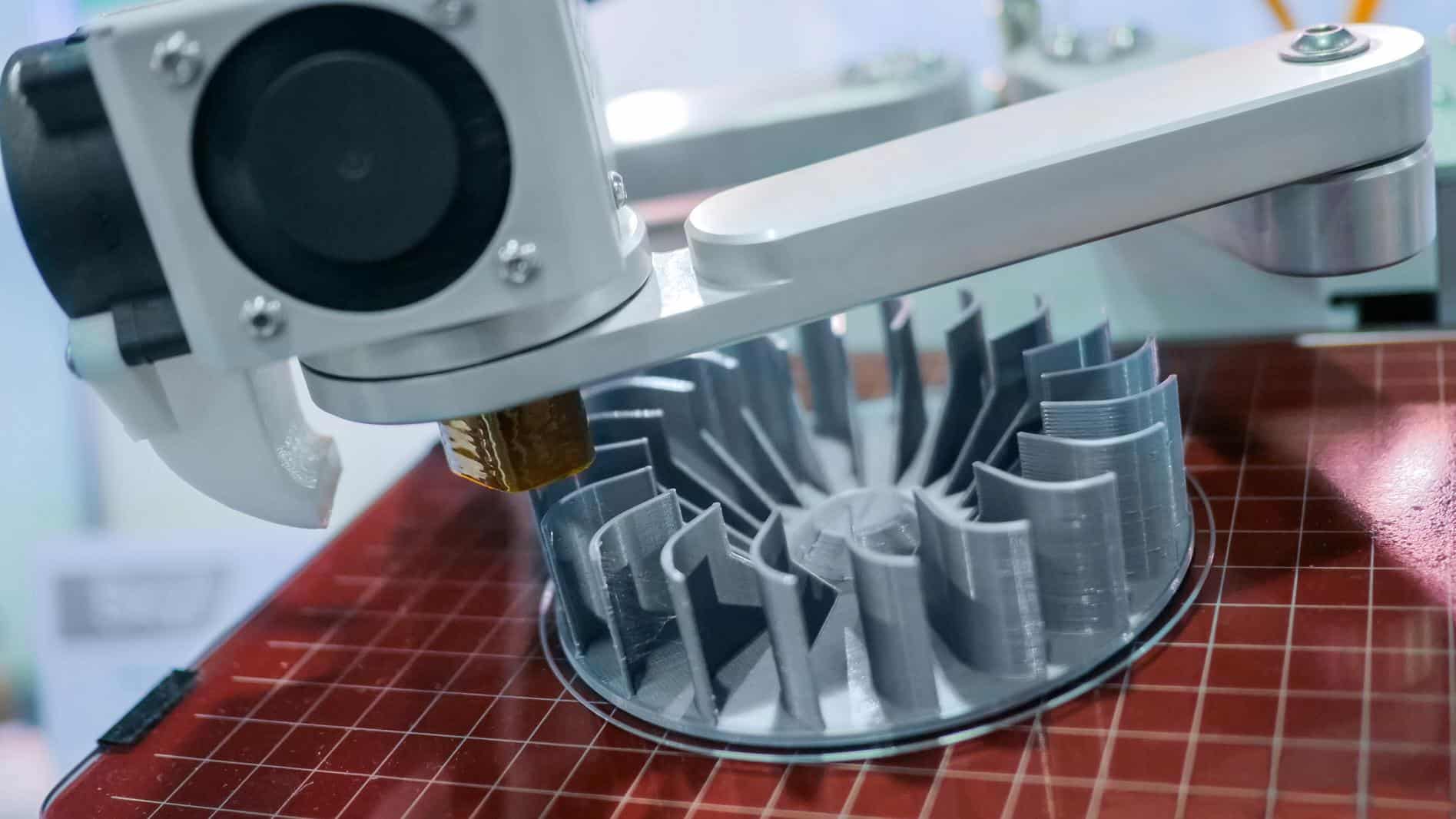

- Create Complex Geometries – Unlike traditional machining, 3D printing can create complex designs that conventional manufacturing cannot create with assemblies of several components. An example is internal voids inside the part to lighter the product. The creation of lighter parts is a significant reason why 3D printing is popular within the aerospace, defense, and automotive industries. And with expensive materials such as metals, the internal voids also add up to cost savings.

- Customized Medical Application – 3D printing allows medical professionals to produce customized items for medical procedures, including custom implants for dentures, hips, spine, & knees. A cranial implant was recently performed with 3D-printed parts. Several additional applications include strong and durable custom prosthetics, custom-fit hearing aids, and procedure-specific surgical instruments. Swabs were in high demand during the pandemic, and swabs were printed to ease the shortage. 3D printing medical research is developing tissues with blood vessels, drugs, heart valves, and organs. Biocompatible materials are essential to these ongoing medical advancements.

- Design and Manufacturing Engineering – 3D printing simplifies the part creation process. The process is more straightforward because Engineers don't have to deal with the numerous constraints associated with subtractive manufacturing technologies. This advantage also saves Engineering time; complex parts, which once required multiple components, can be easily printed into one lightweight part. Multiple set-ups and additional processing time for numerous components are eliminated on the manufacturing floor.

- Efficient Manufacturing – 3D printing is an efficient method of manufacturing products. It is a single-step process and avoids numerous additive manufacturing operations, set-ups, and energy consumption. CNC parts are as much as 10X the cost of 3D printed parts. There is little wasted material, and the process can be automated to run multiple parts continuously. As is the carrying cost of inventory, warehouse and transportation costs are avoided. Local 3D printing operations offer contracted services that can save companies money by avoiding in-house capital acquisition and process and operator development.

- Lightweight Materials – Most materials used in 3D printing are lightweight plastic compounds and engineering materials. This aspect is a huge selling point in the aerospace industry., Materials can be customized to deliver specific performance characteristics in addition to lighter weights, including improved chemical resistance, heat resistance, elasticity, or strength.

- Little Material Waste - Unlike subtractive manufacturing, which removes material for part creation, 3D printing is an additive manufacturing solution that only adds the material required for the part and supports it during the build. The process is also environmentally friendly, with lighter parts and energy savings, but many filaments are recyclable and powdered materials are 95%-99% reusable.

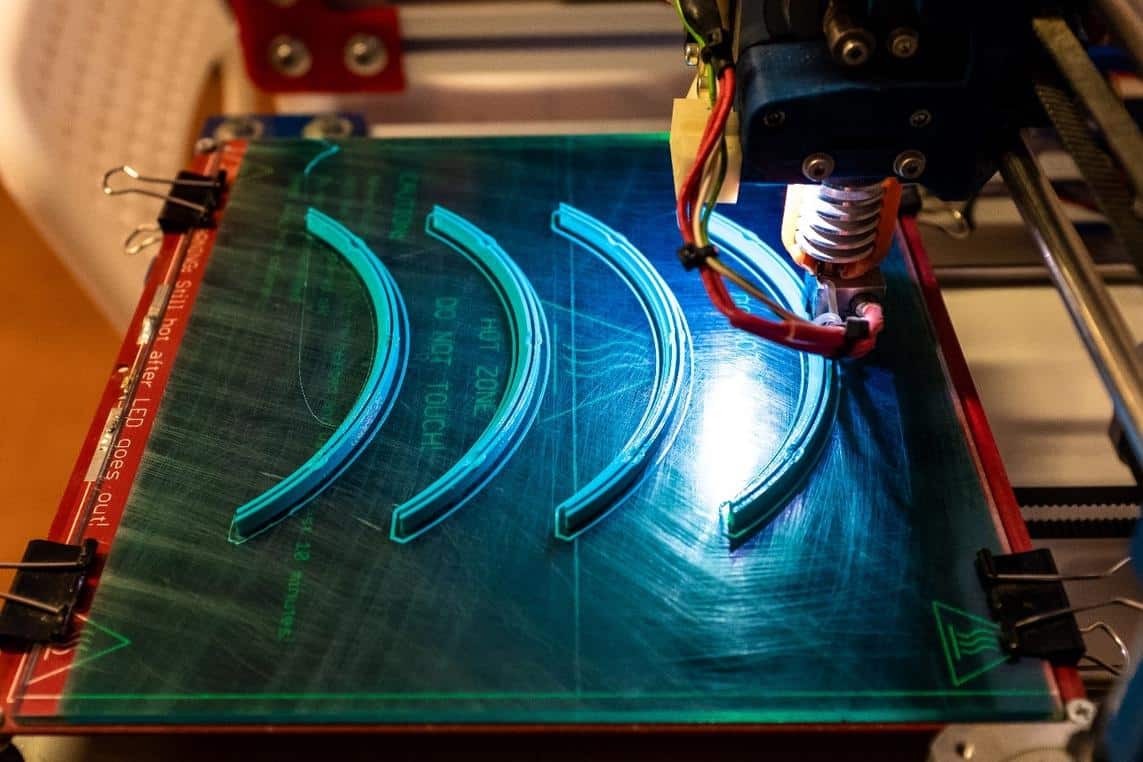

- Quick Part Creation – 3D parts can be printed in hours. This quick turnaround is a considerable advantage over the additional carrying cost of inventory or overnighting parts across the country, assuming they are even in stock.

- Reasonable Equipment Pricing – 3D printers are reasonably priced compared to traditional manufacturing equipment. Entry-level printers for the hobbyist start around $200, and industrial machines are less expensive than CNC machining centers. Material costs for 3D printing may be more costly on the surface. Still, they use less material, so the overall material costs are less costly with lower-priced plastics. Even the more expensive metal powders are cheaper than the subtractive manufacturing material costs.

- Sustainability – The 3D printing process is environmentally friendly, using less material and can reuse powders and recycle most plastic supports. The lighter part also improves fuel efficiency in planes, automobiles, and space vehicles.

What Are the Cons of 3D Printing?

Being a relatively new industry that is proliferating, there are some disadvantages to 3D printing, which include the following:

- Accuracy – Items produced by 3D printers strive to gain the dimensional accuracy of CNC machines and other subtractive manufacturing machinery. The difference is noticeable with 3D parts producing parts ~0.2 mm compared to CNC machines as low as 0.005 mm. This may change with the ongoing improvements in the additive manufacturing industry.

- Cost – While 3D printing equipment is less than its subtractive manufacturing counterpart, it does cost to invest in new technology. Capital equipment, training, and process development can be intimidating.

- Counterfeits and Copyright Infringements – As 3D printing technology gains popularity, the opportunity to create counterfeit products increases. And, as counterfeiting increases, so does copyright infringement. Numerous designs can be downloaded without compensation for the original owner.

- Eliminating Labor – In both a Pro and a Con, 3D printing operations are less labor intensive as one operator can often operate several machines. As with Industry 4.), this is not a problem unique to the 3D printing industry as technology advances.

- Material Availability – The overall 3D printing material selection is relatively small compared to the materials available for other manufacturing processes. Many metal alloys require conversion to 3D printing-compatible materials. Food-safe materials are also quite limited. Thermoset materials cannot be recycled, creating material waste. This is the #1 complaint in the automotive industry and healthcare.

- Part Quality – Certain 3D printing technologies such as FDM, polyjet, and multijet can produce a part with delamination, brittleness, internal stresses and warping, or dimensional issues.

- Post-Processing – The majority of 3D printed parts require some form of post-processing task. Added operations are usually needed, whether heat treatment, polishing, support removal, or machining. Post-processing problems are the primary complaint of the consumer electronics and heavy equipment industries.

- Production Volume - 3D printing was once used primarily for prototypes because the additive process is slower than traditional mass production. Even though the technology can produce low to medium volume production levels, the cycle time is not as fast as traditional additive processes.

- Size – Industrial 3D printers need larger print chambers. Although some specialized 3D printers manufacture large products, much of the technology is limited to smaller builds.

Summary

3D printing is a new industry that is experiencing the pains of rapid growth. In time, materials and technology will catch up with the industry. The forecasted growth of 3D printing is a strong indicator that the complaint will be reduced while approval will continue to increase.

Get multiple quotes for your parts in seconds