Sheet metal service

3DEXPERIENCE Make Online Sheet Metal Service | Compare quotes from different expert manufacturers.

SECURE PAYMENTS

Via payment card or purchase order

PROTECTED IP

Your data is confidential and secure with us. Use your own Non Disclosure Agreement

INSTANT QUOTE

For 3D Printing and CNC Machining, get quote in few seconds.

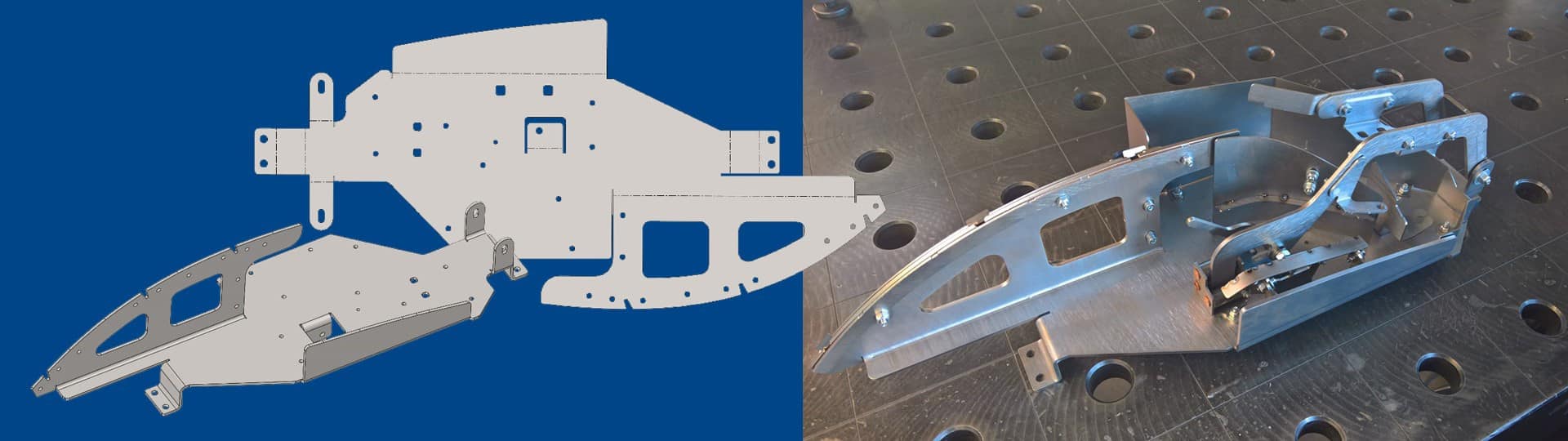

Sheet metal service with 3DEXPERIENCE Make

3DEXPERIENCE Make is an On-Demand Manufacturing platform, which connects designers or engineers with industrial Sheet metal service providers. Our service works mainly with Sheet Metal partners based in North America and Europe. Sheet Metal service is today mainly used for small runs or even large runs, but some of our partners can help you with Mockup or Prototyping (technical or aesthetics).

Whatever your project or your industry, our Sheet Metal service could help you.

Our network of Sheet Metal service providers offers various materials for your project, Metal (Stainless steel, Steel, Aluminium, Cobalt, Cast Steel, H Steel...).

Discover How 3DEXPERIENCE Marketplaces Boost Your Design to Manufacturing Process

You’re in good company. Thousands of leading companies from all industries use our solutions.

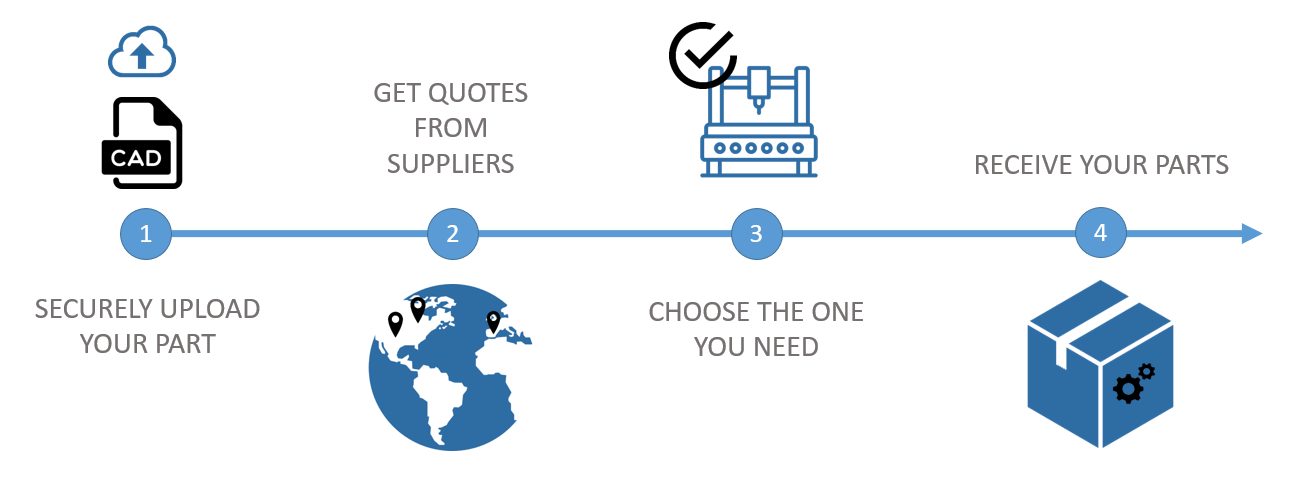

Online Sheet Metal service: how does it work?

Materials of our Sheet Metal Service Providers

Metal

Stainless Steel, Steel, Aluminium, Cobalt, Cast Steel, H Steel...

Features to help you

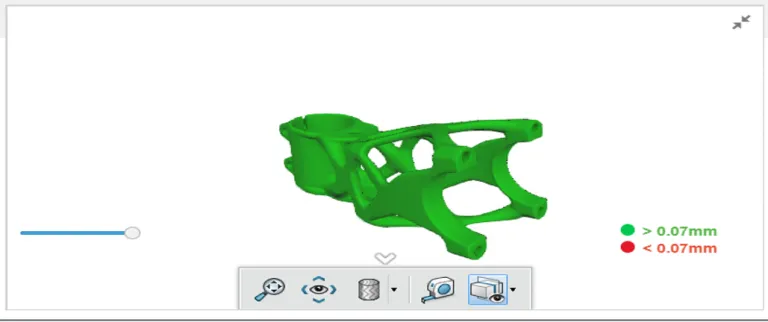

Check & repair or Geometry check is a feature that helps you to understand Geometry issue of your part and could repair it live and online.

Check & Repair

Check & repair or Geometry check is a feature that helps you to detect geometry issue on your part and repair it online and live.

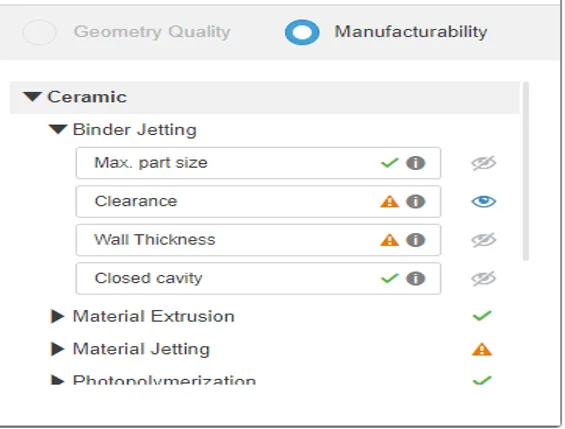

Manufacturability Check

This feature is available only for 3D Printing service. It helps you check the manufacturability of your part, depending on the materials and the process.

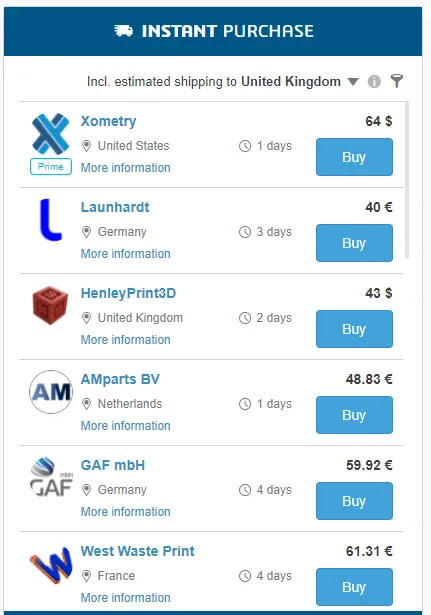

Instant quote engine

Receive in seconds several quotes thanks to our instant quote engine.

What is Sheet Metal?

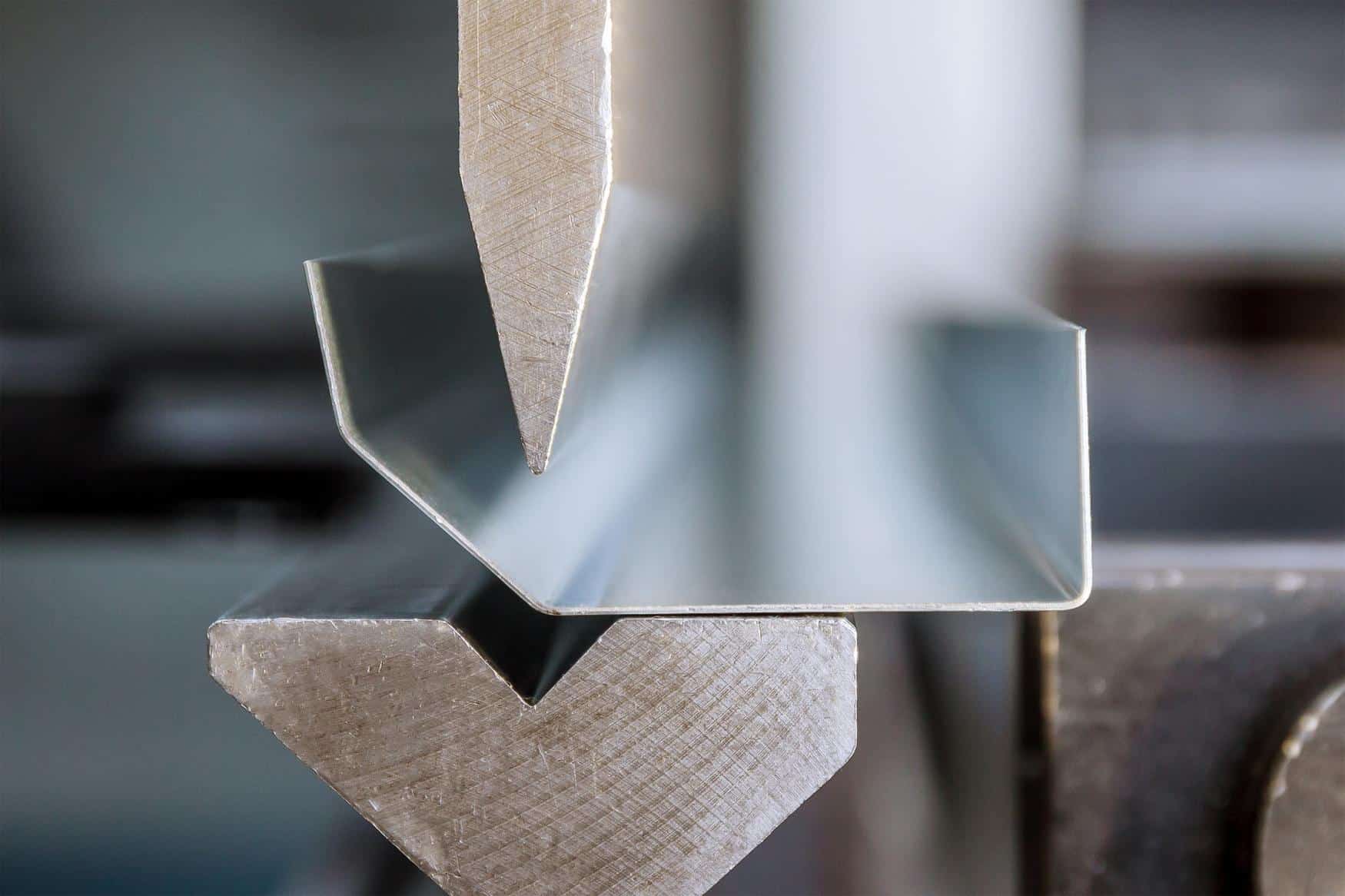

Sheet metal is available in flat pieces or coiled strips that originate from many different metals such as aluminum, brass, copper, steel, tin, nickel, or titanium. It is formed into thin, flat pieces and is one of the most basic materials used in metalworking thanks to its malleable properties enable it to be cut and bent into a multitude of shapes. Decorative objects are often composed of precious metals such as gold, silver, or platinum.

Perhaps without realizing it, we are surrounded by many everyday objects fabricated from sheet metal: from automotive bodies to aerospace fuselages and wings, up to medical tables, sinks, roofs of buildings, and machinery. Historically, the first uses of sheet metal were in the fabrication of swords and cavalry plate armor. Today, Sheet metal services are fabricating decorative uses such as horse tack, jewelry, and sculpture.

There is a significant variation in sheet metal thickness; the thinnest sheets are called foil or leaf, and pieces with a thickness greater than 6 mm (0.25 in) are considered plates.

Questions people ask about Sheet Metal Service

Sheet metal service, fabrication and manufacturing have existed since antiquity; because of current technological advances, the difficulty of shaping metal has decreased and the market has grown to a worldwide marketable service value of 14.8 billion U.S. dollars in 2020, with a product value of around 265 billion USD. Despite the supply chain disruptions of the new decade, the market is poised to continue to see a growth rate of 2.6%. This makes it more imperative to adapt to the increased costs of raw materials, while still increasing the productivity of manufactured products.

Sheet Metal, how much does it cost and which materials to use with?

The cost of sheet metal fabrication is divided into two parts, material, and manufacturing. In regards to material cost, steel makes up more than half of the material used for sheet metal. There are several grades of steel, with grade 304 being the most common, providing a balance of formability and weldability while still being corrosion resistant. Other grades of steel vary in properties such as heat resistance, corrosion resistance, strength, and formability with all of these factors and more affecting cost.

Aluminum makes up about a third of all sheet metal materials. Its flexibility and cost-effectiveness make it a popular candidate for fabrication, despite not being as tough as steel. Steel is typically better suited to building materials and other candidates where strength and density are important factors, whereas aluminum is suited to products requiring weight savings while still maintaining structure such as aircraft and automobiles. Other materials used in sheet metals include copper, brass, titanium, cobalt, tungsten, and more.

The other critical component in choosing the material is the thickness, better known as gauge. The lower the gauge, the thicker the material and heavier it will be, which will vary between material types. Higher gauges equate to thinner sheets which cost less and are more malleable. It is best to stick to common gauges, as custom sheet thickness outside the accepted common gauges will incur a higher cost. Keeping to one gauge as much as possible also reduces cost. Seeking expert advice is the best solution to finding what material will work best for a given application and the experts at Dassault Systemes can offer quotes for cutting and forming aluminum and steel.

Sheet Metal Service, which Fabrication Techniques?

Decreasing complexity is a simple rule of thumb in the design of any product to decrease cost, and this principle holds true in sheet metal fabrication. Using simple folds within the design decreases cost, with bend angles that are equal to or greater than the radius of the sheet’s gauge. It is crucial to note the maximum amount of bending force and bend allowance a material can take, as going past these limits may not only affect the composure of the fabricated product but break and waste material. These bends should have a consistent radius as well a uniform orientation to avoid moving and reorienting the part during fabrication. On thicker gauges, small bends should be avoided as they can be hard to form as well as inaccurate.

Simplification also applies to the methods of material manipulation itself. Labor cost increases every time the sheet metal is moved from one machine to another, different folds, bends, and cuts are introduced, and anytime a step is added in the process. Automation in the manufacturing process can be introduced to not only remove unnecessary steps but reduce error points where costly mistakes can waste material.

Manipulating the material to form, whether by bending, rolling, forming, expanding, or stamping is all dependent on its tolerances. The necessary amount of tight tolerances should be limited in order to reduce costs. Tight tolerances in some designs may not allow for as much bending and necessitate the need to split a design into multiple parts and require it to be fastened, bolted, or welded together. Refer to a guide, such as this one, or consult an expert on what a particular metal’s given tolerances are depending on its gauge.

What kind of Technological Optimization?

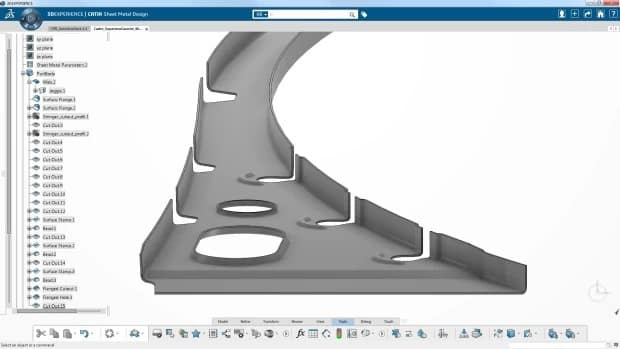

Today’s CAD software brings the powerful advantage of being able to apply all these techniques and more when initially drafting designs. This not only further optimizes the quality and durability of the final product, but reduces manufacturing costs anywhere from 40%-60. Dassault’s SOLIDWORKS combined with 3DEXPERIENCE tools allows correlation between the dimensions, folds, bends, cuts, and other features of the sheet metal part design, and the properties of the planned material and gauge itself. The software itself is also capable of applying these properties to the final application of the design to gauge tensile strength, geometry, and operability with other materials, forces, and stresses.

Many of the tools to help decrease costs are already built into SOLIDWORKS itself. The CostingManager tool can help estimate not only material, but bending, cutting, welding, and other deformation operations that will incur total production cost, allowing for greater control and management of the design to cost balance. Other tools allowing to switch between folded and unfolded sheet metal designs give a better visual representation as well as drafting and editing points on a part design. Through collaborative manufacturing preparation, other experts, team members, and partners can delve into designs and provide input all on the same interface.

Much of this is automated and interoperable with other design formats, applications, and other data points to further streamline the sheet metal design process. Other add-ons like SheetMetalWorks help to further calculate points of cost reduction. 80% of design time is reduced through commands and calculations that automatically eliminate design errors. The ability to track costs, tolerance, and bend calculations and errors in real time have given designers greater flexibility to optimize sheet metal designs without the time-intensive calculations, redrafts, and trial and error prototyping that was commonly expected in the past.

Discover our other manufacturing services

Get multiple quotes for your parts in seconds