3D Printing

Discover what is 3D Printing and its usage in the industry.

Discover SOLIDWORKS 3DEXPERIENCE for Makers

What is 3D Printing?

3D Printing is the process of creating objects by depositing layers of material on top of one another. 3D Printing is called additive manufacturing (AM) instead of traditional subtractive methods like CNC milling when used for industrial production.

This technology has been around for about four decades, invented in the early 1980s. While 3D printing started out as a slow and costly technique, extensive technological developments have made today’s AM technologies more affordable and faster than ever.

How does 3D printing work?

A digital 3D model is sliced into hundreds of thin layers by dedicated software to export in G-code format. This 3D printing format is a language that the 3D printer reads to know precisely when and where to deposit material.

Each layer corresponds to the exact 2D shape of one section or slice of the object. For example, if you were 3D Printing a pyramid, the first layer (bottom) would be a flat square, and the last layer (at the very top) would be a tiny dot.

The layers are consecutively 3D printed one at a time until you obtain the fully printed object.

Common 3D Printing Technologies

There are different ways to 3D print objects. The leading 3D printing technologies available today are:

- FFF (fused filament fabrication) or FDM (fused deposition modeling), which use spools of filament

- SLA (stereolithography), a technology that solidifies the photosensitive resin

- PBF (powder bed fusion), a range of powder-based methods that fuse particles with powerful lasers

- Material or binder jetting, where tiny droplets of material are deposited onto a bed of powder

These 3D printing technologies each have their own strengths and weaknesses and can adapt to different use cases and industries.

Why use 3D Printing?

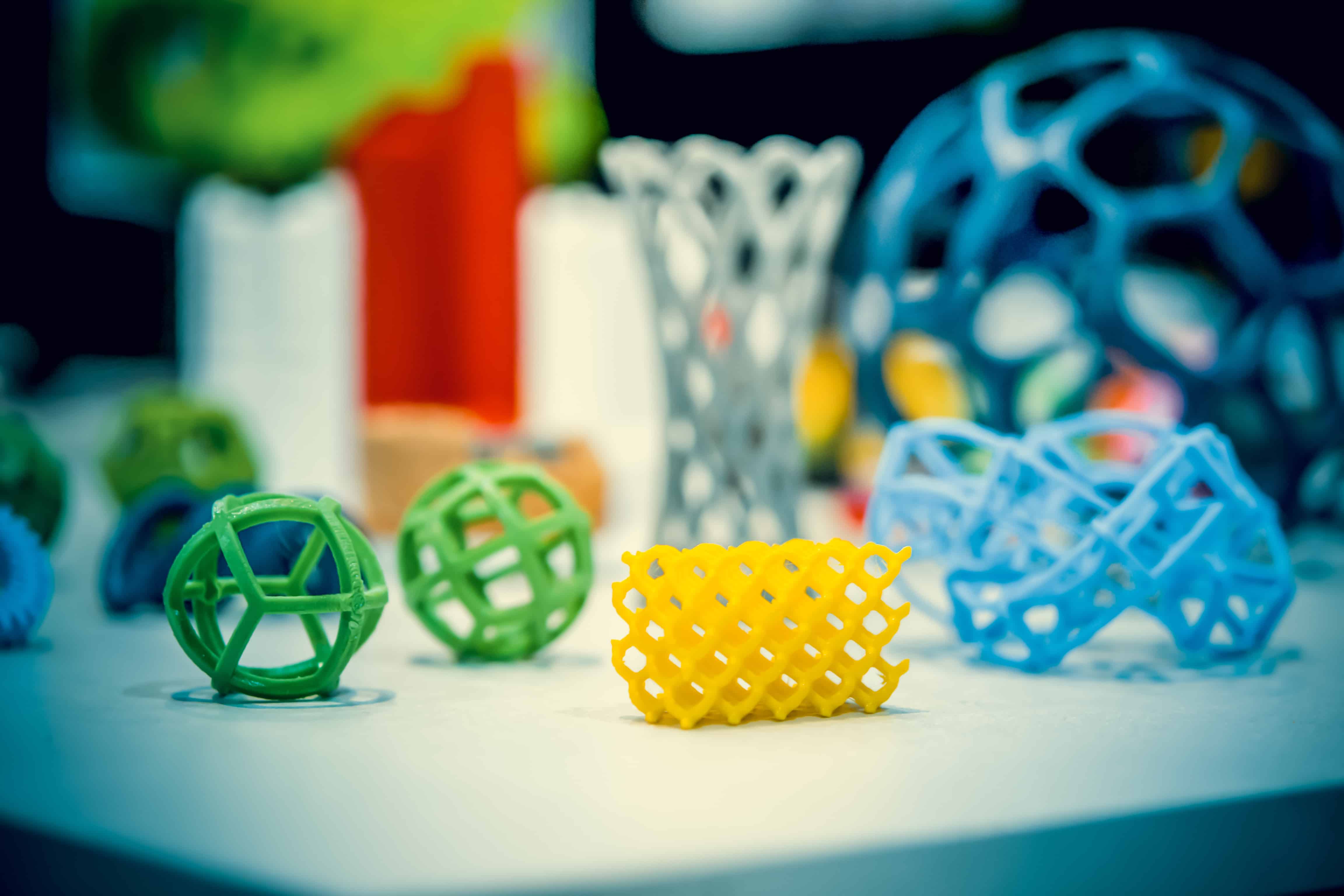

3D Printing offers a considerable number of advantages, the most significant one being the ability to produce highly complex designs that would be impossible to make otherwise.

Another significant benefit of 3D printing is speed. Although 3D Printing an object can take hours or even entire days, it is still much faster than mainstream production methods such as injection molding.

Prototyping—which is one of the most popular professional uses for 3D printing—can be done in-house with little to no lead time, and design iterations can be implemented and printed on the spot.

This technology also offers many 3D printing material possibilities.

What can you 3D print?

It is possible to 3D print with almost any material. The most common 3D printing materials are plastic-based, ranging from standard PLA to advanced, highly resistant polymers such as PEEK or PEI, and much more. It is even possible to reinforce thermoplastics with carbon fiber or glass fiber.

Some niche 3D printing materials are gaining popularity, too. Scientists and biologists are experimenting with 3D bioprinting, chefs can have a go at food 3D printing, and contractors are increasingly looking into concrete 3D printing.

What can 3D Printing be used for?

Consumer-wise, 3D printing can help create personalized trinkets and decorations, practical household objects, figurines, and more. However, this technology presents the strongest advantages for professional use cases, which this article will focus on.

Thanks to a large number of additive manufacturing (AM) technologies available and the diversity of compatible 3D printing materials, an almost infinite range of applications exist with 3D printing.

Rapid prototyping

Prototyping is the most common use for 3D printing in the professional world. Called also rapid prototyping, you quickly design a model and 3D print shortly after.

The world recently witnessed one of the most impressive demonstrations during the global coronavirus pandemic. Respirators, swabs, and face shields were designed in a matter of days and mass-produced by the thousands in just a few weeks.

3D models continuously evolved according to gradual feedback from doctors and researchers. This immediate response was highly effective in the fight against the virus and perfectly illustrates the potential, adaptability, and speed (time-to-market) that additive manufacturing offers.

On a lighter note, these benefits could apply to normal, more fortunate situations in various industries, including Aerospace, Automotive, Education, Oil & Gas, Medical, and the list goes on.

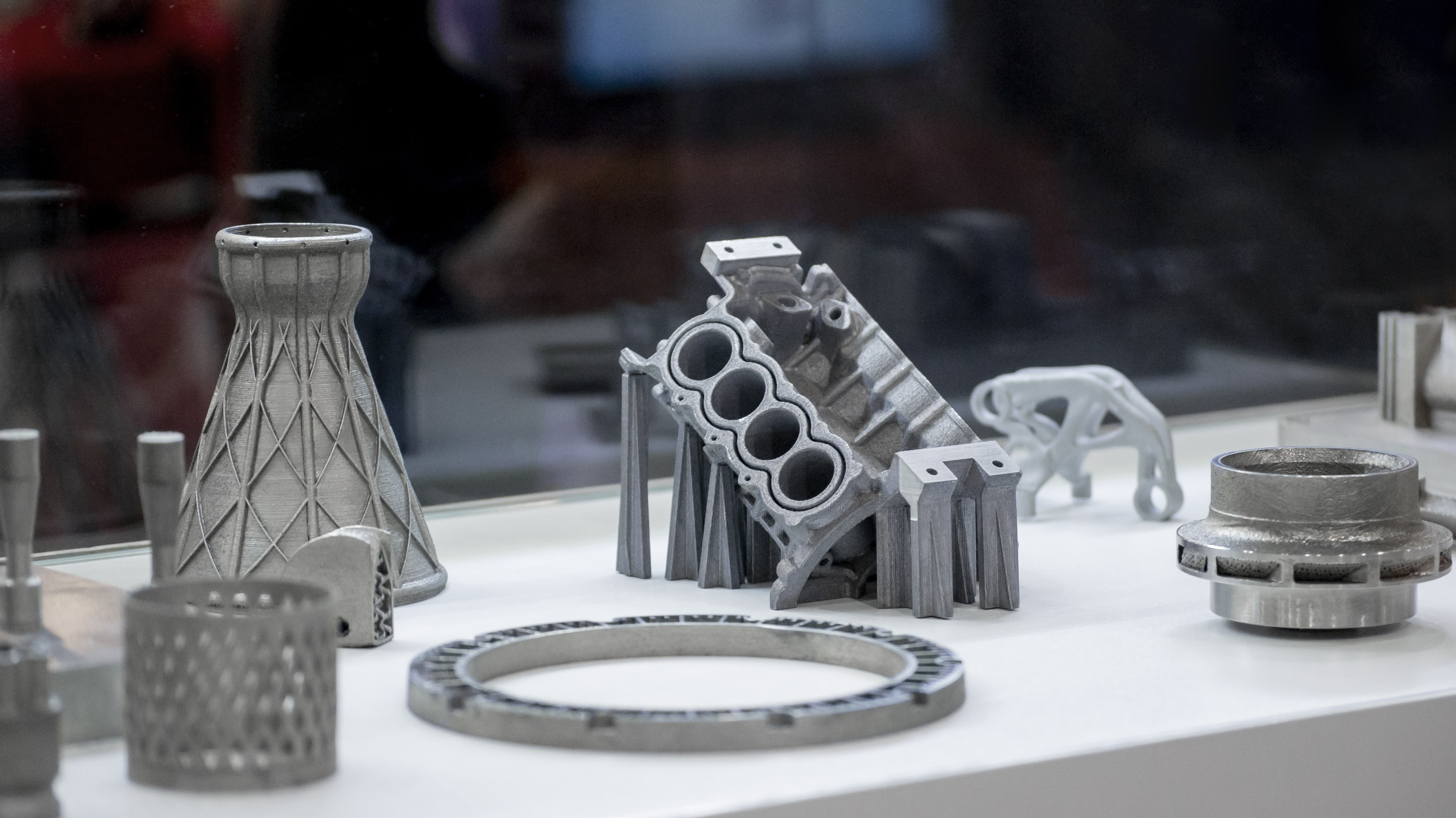

End-use parts

With some post-processing, today's industrial-grade 3D printed parts are of such good quality, and industrials can use them directly.

Some automotive brands, for example, utilize additive manufacturing to produce certain parts of a car's interior or motor components. This is also the case in aerospace, where weight optimization is of utmost importance. Indeed, 3D printing technologies can increase part strength and resistance while employing lighter materials.

Nonetheless, there are obstacles to overcome for 3D printing to be viable for end-use items. The parts need to be certified, especially for highly regulated industries like aerospace. They must be identical to obtain AM certification, which requires extremely precise 3D printers and standardized processes and materials.

Tools, Jigs, and Fixtures

Tooling is another leading use for 3D printing. 3D Printing service can manufacture tools, jigs, and fixtures quickly, then and there without holding back the production chain due to a missing device.

This also enables professionals to adapt their tools and utensils to the object or part they are working on and not the other way around.

Traditional methods like injection molding can take several weeks to be backed by a consequential budget to obtain a new, custom tool. 3D Printing isn't necessarily better than conventional manufacturing techniques for every use case, but it is often quicker and more affordable.

Mass customization

Mass production offers the significant advantage of lowering costs at scale, but each part must be identical.

Additive manufacturing, however, is enabling brands to mass-produce customized objects. This is called mass personalization or mass customization. Manufacturers can benefit from the same economies of scale while offering the added value of customization to their customers.

How 3D Printers Work: An Overview of 3D Printing Technologies

3D printers are able to replicate 3D objects just as regular 2D printers can print text or images on paper. Instead of one layer, there are hundreds or thousands of stacked layers.

Before any printing happens, manufacturers must prepare 3D models. You can design your own 3D object with CAD software like SOLIDWORKS, or you can find and download a 3D model online.

Once the 3D model is ready, dedicated slicing software (a.k.a. "slicer") must slice and convert into a format that the 3D printer can read.

The object can then be 3D printed. Numerous methods exist, but the main 3D printing technologies are the following:

- FFF (fused filament fabrication)

- SLA (stereolithography)

- PBF (powder bed fusion)

- Material or binder jetting

3D printer manufacturers often use their own acronyms, which can be confusing, but the four categories listed above are an excellent way to get a standard classification. The following sections will explain each of these general 3D printing technologies.

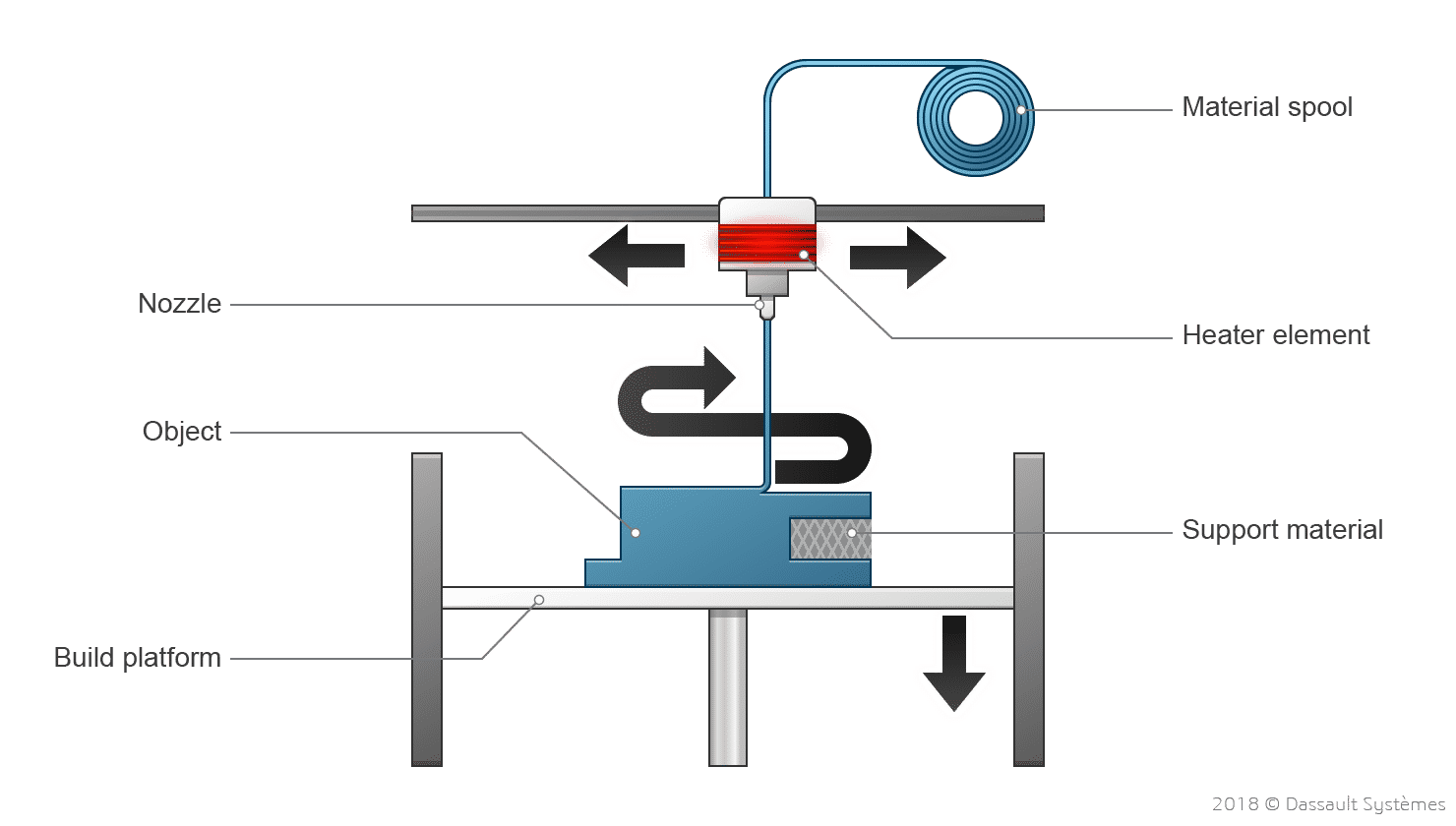

FFF (Fused Filament Fabrication)

When people explain what 3D printing is, most tend to illustrate filament-based 3D printing methods as it is the most commonly used and easy to understand.

An FFF (or FDM, for Fused Deposition Modeling) 3D printer draws a layer of melted plastic onto its print bed or builds a plate. The melting happens inside an extruder, which heats up the plastic filament as gears push it through the nozzle.

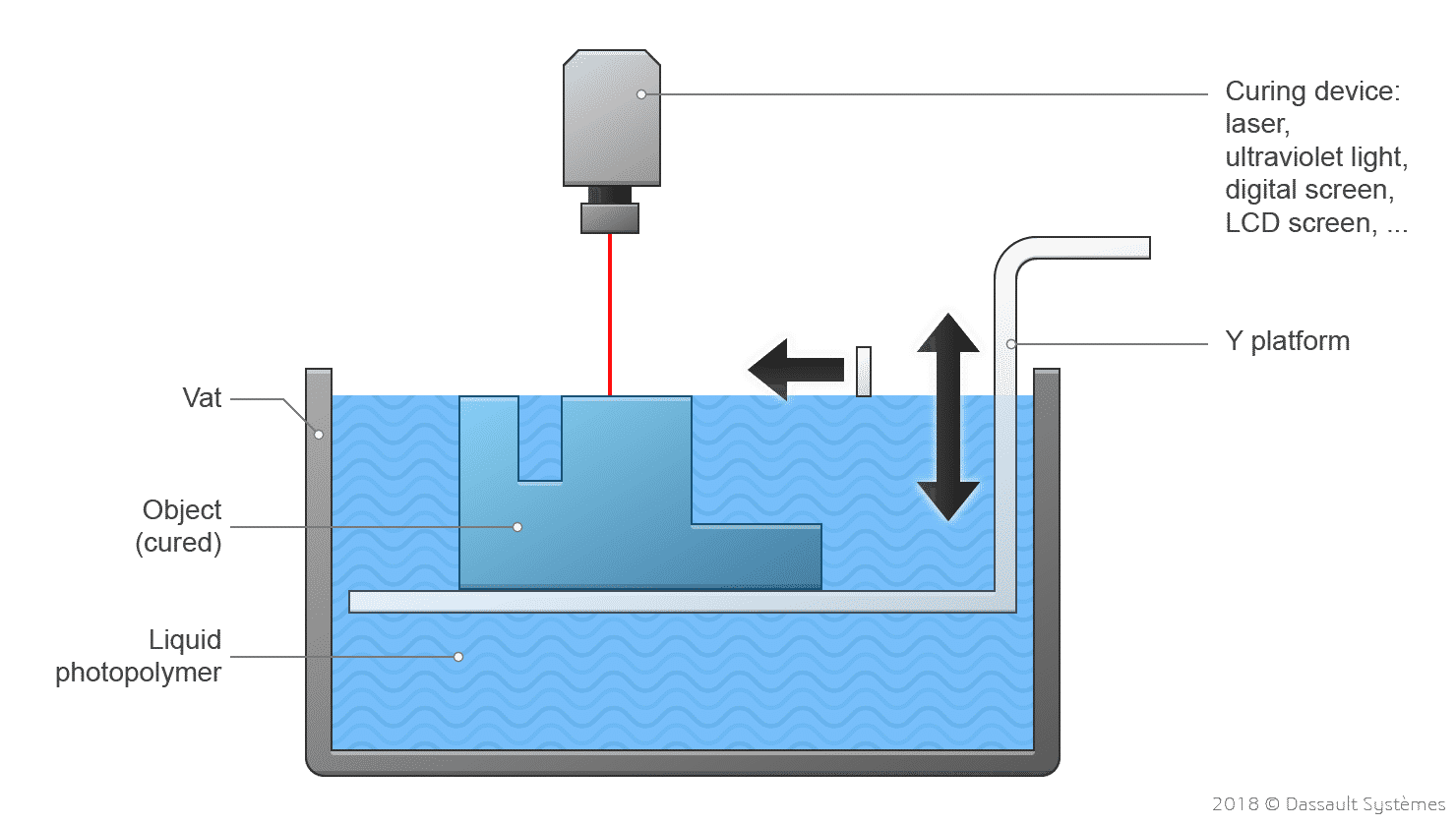

SLA (Stereolithography)

Stereolithography is a resin 3D printing technique that uses a laser or light source to solidify photosensitive resin.

The solidification process is known as curing, and it can happen in several ways:

- Laser SLA: a laser cures the resin point by point, layer after layer.

- DLP (Digital Light Processing): a device projects light that is precisely redirected towards the resin thanks to a mirror system.

- MSLA (Masked Stereolithography): a device that projects light selectively masked by an LCD screen, as LCD stereolithography.

Resin 3D printers are able to print thinner layers than FFF 3D printers, offering a much higher level of detail that is sought after by jewelers or dentists, for example.

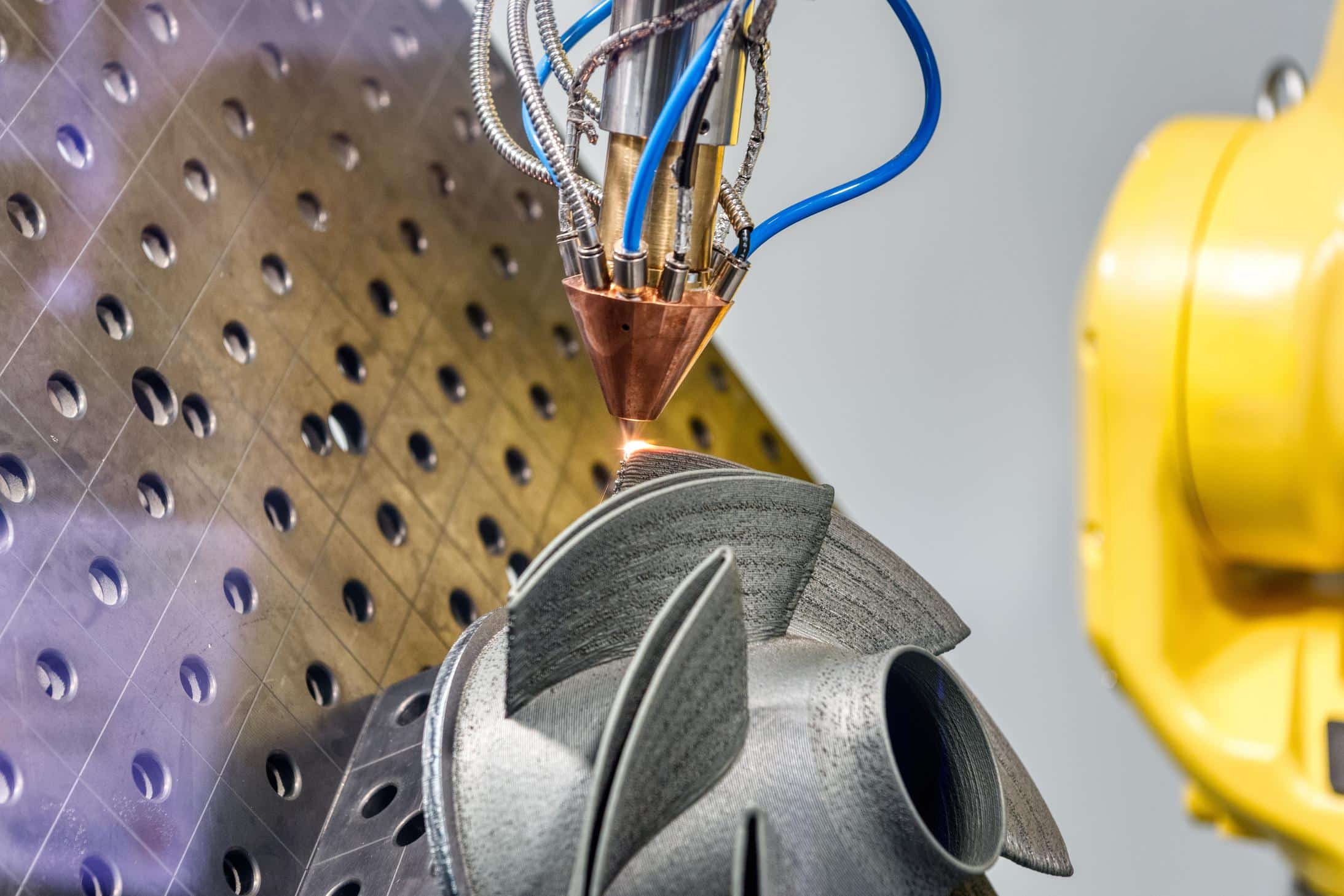

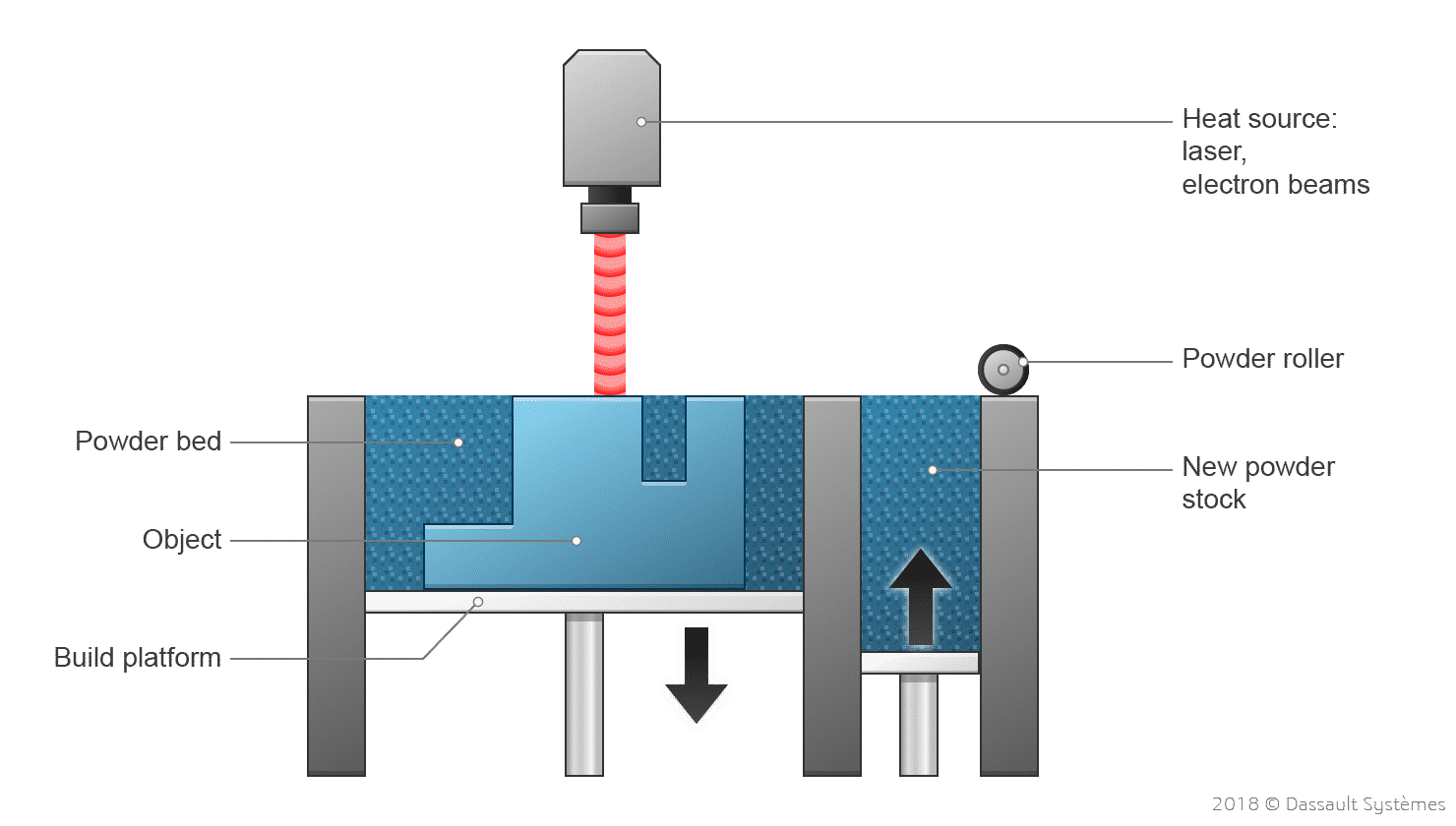

PBF (Powder Bed Fusion)

There are several powder-based 3D printing methods, the most common ones being SLM (Selective Laser Melting) and SLS (Selective Laser Sintering).

A powerful laser source is aimed at a powder 3D printing material bed. The heat from the laser makes select particles of powder fuse or melt together. These techniques are often used to 3D print metal but are also compatible with plastics like Nylon.

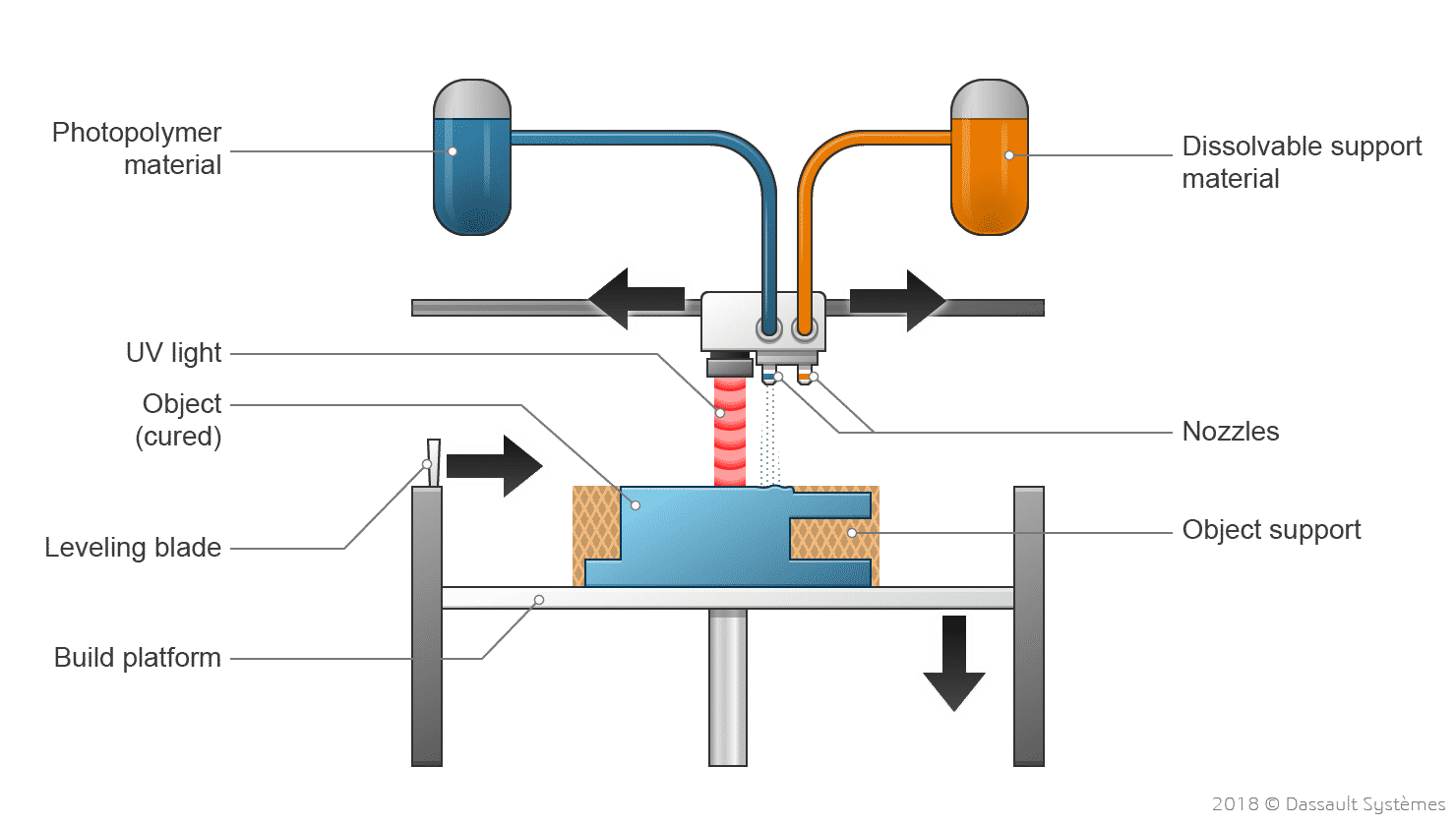

Material and Binder Jetting

Material jetting 3D printers are what resemble 2D printers the most. Hundreds of tiny nozzles that deposit ink onto a layer of powdered material mount them.

Either the ink is the goal material, or the ink is a binding agent (basically glue) dropped onto the goal material.

The 3D Printing Industry Ecosystem

The 3D printing industry encompasses much more than 3D printers and their manufacturers. It's fueled by a range of other key players that, though often overlooked, are essential to making this technology thrive.

Aside from 3D printer manufacturers, there are material manufacturers, software companies, post-processing machine manufacturers, and service providers.

Many important media outlets and event organizers also largely contribute to the market's evolution, though it won't be the focus in this article.

3D printer manufacturers

Starting with the obvious, 3D printing would not exist without the actual machines that do the work and the companies that produce them. There are multinational companies such as 3D Systems at the unicorn level and startups like Desktop Metal and SMEs.

The competition is fierce, meaning technologies are moving fast and prices are lowering. Nowadays, the most affordable 3D printers are available for a couple of hundred dollars or euros. However, they are, of course, far from providing the same performances as professional or industrial 3D printers.

3D Printing Material Manufacturers

3D printers need consumables to print. These consumables are available in various formats, from filament, resin, and powder to special inks. There's also a wide choice of 3D printing materials, including dozens of thermoplastics, metals, and even concrete.

Most 3D printer manufacturers sell their own consumables—which may or may not be rebranded from major chemical companies like Arkema—or specialized 3D printing material manufacturers.

Software companies

Software is another essential part of the additive manufacturing ecosystem. The first type of 3D printing software that comes to mind is CAD suites like SOLIDWORKS and slicers, which prepare 3D files for printing.

There are also solutions to manage fleets of 3D printers, also called 3D printer farms. This type of software is generally developed in-house by the 3D printer manufacturer.

More complex solutions must be developed and used for end-to-end additive manufacturing chains. Manufacturing Execution Systems (MES) is the common term for them, tracking and monitoring parts from the beginning of the printing process to the very last post-processing steps.

Post-processing System Manufacturers

Post-processing is perhaps the most hidden face of 3D printing. Paradoxically, 3D printed parts almost always need to undergo at least some form of post-processing to finish the work.

This umbrella term groups several steps and techniques, from support removal and depowdering to surface finishing and part coloring.

Some 3D printer manufacturers bundle dedicated solutions with their 3D printers, but there are a number of companies specializing in post-processing machines, too.

Additive manufacturing service providers

For those that don't necessarily have the funds to acquire a 3D printer or enough time and space to dedicate to one, 3D printing services are a great option. There are literally dozens of service providers to choose from all over the world.

They enable users to upload their design and have it 3D printed with a specific 3D printing technology or material, benefitting from the provider's experience and industrial-grade AM systems.

Main 3D Printing Materials: What Can You 3D Print With?

There is an incredibly vast amount of 3D printing materials available today for different 3D printing technologies. From thermoplastics to metals and ceramics, and from food to organic living cells and concrete, it's possible to 3D print with almost any material.

Thermoplastics: Standard, Engineering, and High-Performance

Plastic represents the most common 3D printing material. We can categorize 3D printing thermoplastics into three main types:

- Standard

- Engineering or performance

- High-performance

Both hobbyists and professionals often use standard plastics. They namely include PLA and ABS, which are easy to 3D print.

Like Nylon or PETG, engineering plastics are tougher to print, requiring higher extrusion temperatures and, typically, a closed frame to protect from drafts or temperature changes.

High-performance polymers like PEEK are privileged when parts must withstand high temperatures, chemicals, humidity, and more. These 3D printing materials cost more and require a high-temperature 3D printer.

Composite 3D printing materials

To benefit from various benefits provided by different kinds of materials, it is possible to 3D print composites, which are a mix of two or more materials.

Composite materials can include basics like wood-filled PLA but can also contain very strong and resistant materials like carbon-fiber-filled Nylon or PEEK. It is even possible to deposit long strands of fiber directly during the 3D printing process with the right equipment.

Metals and ceramics

An increasing number of manufacturers in the 3D printing ecosystem are developing solutions to 3D print metals and ceramics.

Most of these solutions are expensive, industrial-grade additive manufacturing machines that produce green parts. Post-processing steps such as debinding or sintering are necessary before these raw parts are ready for end-use.

Concrete 3D Printing

3D Printing for the construction industry is also gaining ground thanks to special concrete mixes that operators use to print foundations, bridges, outdoor structures, sculptures, and more.

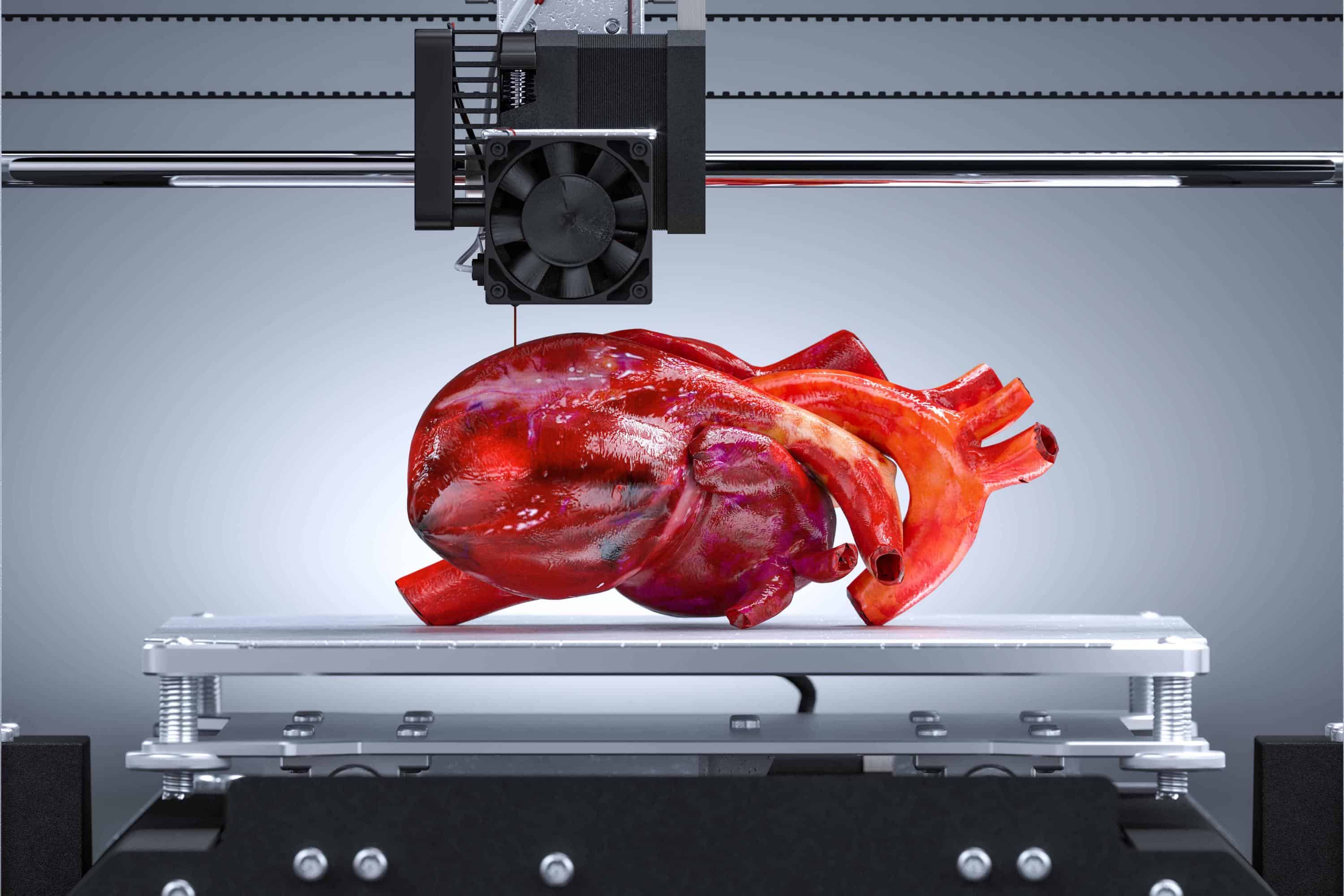

3D bioprinting

Although 3D bioprinting still has a way to go before it is possible to 3D print human organs that can actually be transplanted, the technology is capable of 3D Printing a variety of living cells.

Specific hydrogels typically contain these cells. They can be extruded to grow skin or cartilage at low temperatures.

Food 3D Printing

At the moment, food 3D printing possibilities are pretty limited. Food must be in some form of extrudable paste to be 3D printing.

That's why the most common form of food 3D printing today is chocolate 3D printing, though it is still challenging to print; Temperature fluctuations modify the taste of chocolate. Hence, it is essential to heat it just enough to be printed and sufficiently cool it down for the layers to solidify.

These are only just the main 3D printing materials available, and they all require different kinds of 3D printers. Sometimes, it's easier to use a 3D printing service provider, as they have access to all or most of these materials and 3D printer types.

What 3D Printing File Formats exist?

It is essential to distinguish 3D file formats and 3D printable files. 3D models, or digital blueprints, must be in a format convertible into a 3D printable format.

3D File Formats for 3D Printing

Dozens of 3D file formats exist due to the vast amount of 3D software options available. Some are specific to certain use cases, while others are relatively standard formats, like the ones we list below.

Choosing the proper format will depend on the 3D printing technology used and the 3D printing material.

STL

STL is the most common type of 3D printing file format and was actually the first to be invented specifically for 3D printing. It stands for stereolithography, which was also the first 3D printing technology globally.

This type of 3D printing file includes the 3D shape of the object as a solid block of thousands of tiny triangles, which form what is called a mesh. It is ideal for single-material, single-color 3D prints.

OBJ

Thanks to its multicolor capacities, the open-source OBJ (OBJ for objects) format is gaining popularity.

With more and more color 3D printers on the market, OBJ files could soon overthrow the STL format's long-standing reign. However, the number of software solutions to edit or repair OBJ files is limited.

AMF

AMF is an acronym for Additive Manufacturing File, also known as STL 2.0. The aim of AMF is to replace heavy, monocolor STL files gradually. It stores various properties, including the 3D object itself, colors (a.k.a. textures), materials, and metadata.

Whereas the STL file format only uses regular flat triangles, the AMF file can use curved triangles. Only a handful of software suites, including SOLIDWORKS, are able to support this kind of file.

3MF

3MF stands for 3D Manufacturing Format. Microsoft developed the 3MF file type in collaboration with some of the biggest brands and manufacturers in the 3D printing industry, including Dassault Systèmes, 3D Systems, Stratasys, Materialise, and more.

Their goal with 3MF is to provide a solid alternative to STL files, much like AMF, while keeping it simple, "lightweight," comprehensive, and—importantly—free to exploit by all software suites.

Indeed, the widespread adoption of the 3MF file extension must be open source to allow all developers to integrate the file type to their software freely.

3D Printable File Format: G-Code

The 3D file formats previously mentioned must be converted to a file type that 3D printers can read. Today, the G-code format largely dominates the market.

STL, OBJ, AMF, 3MF, and other 3D files are sliced into hundreds or thousands of layers, with information on where to start, when to stop, how fast to deposit material, when to switch colors (not applicable to STL files), and more. That is part of how 3D printers work.

G-Code also works for other kinds of computer-controlled machines such as CNC lasers and engravers.

3D Printing Trends for Industrial Applications

While 3D Printing used to be a trend itself, there are now several specific fields within the ever-growing 3D printing industry that are emerging (or continuing to emerge) as their own trends.

Here is a quick overview of some of today's main 3D printing trends.

3D Printing demanding materials

Today in industrial applications, users are searching for materials with increasingly advanced mechanical properties. There are namely three niche-material markets where both hardware and material manufacturers are pushing for innovation.

Metals

Metal 3D printing isn't a novelty, but it has been gaining quite a bit of traction lately. The competition is tough, with manufacturers striving to answer the equally strong demand for metal printers, metal 3D printing materials, and metal 3D printing services while lowering prices.

Composite Materials and Continuous Fibers

The main interest in composite 3D printing comes from combining desirable properties from two different materials. Typically chopped carbon fibers reinforce a thermoplastic filament like Nylon or PEEK for added strength and resistance.

Continuous fiber prints are at a level above regular composite 3D printing. In a nutshell, parts are reinforced with continuous strands of fiber—often carbon or glass fiber—during the 3D printing process. This makes it possible to focus on strengthening specific weak points and further optimizing a part's weight.

PEEK, PEKK, and PEI high-performance materials

We generally consider PEEK, PEI, PEKK, and other PAEK derivatives, as high-performance materials thanks to their above-average resistance to high temperatures, chemicals, water, and other extreme conditions.

However, these PAEK materials must be 3D printed with high-temperature 3D printers. There were only a handful of these printers a few years ago, but now there are dozens. They can reach higher temperatures, and entry-level solutions are more affordable than ever.

Post-processing, a high-potential market

Post-processing 3D printed parts is a time-consuming process, including removing support structures, post-cure resin objects, depowder parts, or applying surface finishing techniques.

Previously, since professionals mainly used 3D printing for occasional, single parts or small production series, post-processing didn't represent as big of a bottleneck as today.

As businesses scale up their 3D printing production and diversify their use cases for the technology, the demand for efficient, automated post-processing solutions is booming.

Software and automation

For 3D printing to become a solid manufacturing alternative, powerful, intelligent software and machines must back the end-to-end 3D printing process.

This begins with automatic file preparation, where software can automatically repair the models if needed and place them in a way that best makes use of the available build space.

It is also possible to automate material handling and load up to a certain extent; industrial additive manufacturing systems often use material cartridges or have large material tanks that can last for several days of non-stop printing.

In 3D printing factories and farms, it's even possible to automate print removal with a mix of vacuum systems, conveyor belts, or robots. They direct the parts to different post-processing machines before being ready for use or sale.

Such additive manufacturing factories are mainly run by MES (Manufacturing Execution System) software. 3D printer manufacturers are increasingly focusing on these kinds of software and automation capabilities.

3D Printing Service: How to Choose the Right One?

Choosing the right 3D printing service is no easy task. There are many variables to take into considerations, the main ones being:

- File preparation

- Technology

- Materials

- Finishing options

- Certification

- Lead time

File preparation

Not all 3D models are 3D printable, especially if your file isn't in the proper 3D file format. Some 3D printing service providers have teams ready to help you optimize your models or even design your prototype from scratch.

Technology

Once your file is ready, you'll need to decide how you want your part to be 3D printed. Many leading service providers have access to FFF, resin, and powder-based 3D printing technologies.

On-demand manufacturing platforms also have other types of manufacturing possibilities, both subtractive and additive. It can be interesting to combine several technologies.

For example, you could mix 3D Printing and CNC milling for tighter tolerances or 3D printing and injection molding for a higher return on investment.

Materials

3D printing materials are another aspect of choosing a 3D printing service. Popular materials include plastic, composites, wax, metals, sand, and ceramics.

If you already know which material you'd like to print with, you can significantly reduce your search perimeter.

Finishing options

Functional

Depending on what is the usage of your part, you may need finishing options to undergo certain post-processing techniques to enhance its strength or resistance to specific conditions.

Heat treatments, such as annealing or Hot Isostatic Pressing (HIP) will make parts more robust. If you need your part to resist humidity, you can choose a waterproof coating.

Aesthetic

What do you want your part to look like or feel like? There are dozens of surface finishing options, from sanding to polishing and tumbling, and hundreds of colors—standard, shiny, or matte—to choose from.

After going through different finishing techniques, it's almost impossible to tell if a part was 3D printed or traditionally manufactured.

Certification

The ability to certify parts is a growing trend in the 3D printing industry. Indeed, it is crucial for users to know that the objects they buy provide a certain level of safety and durability.

Only a select few of the hundreds of available service providers can produce certified parts. You can order parts that respect international standards set by leading organizations such as PRI (Performance Review Institute) or ISO (International Organization for Standardization).

Lead Time

If you need next-day delivery, you'll have to choose a provider capable of doing so. As with any service, some 3D printing bureaus are quicker than others.

Remember that lead times will significantly depend on the technology and finishing options you decide to use.

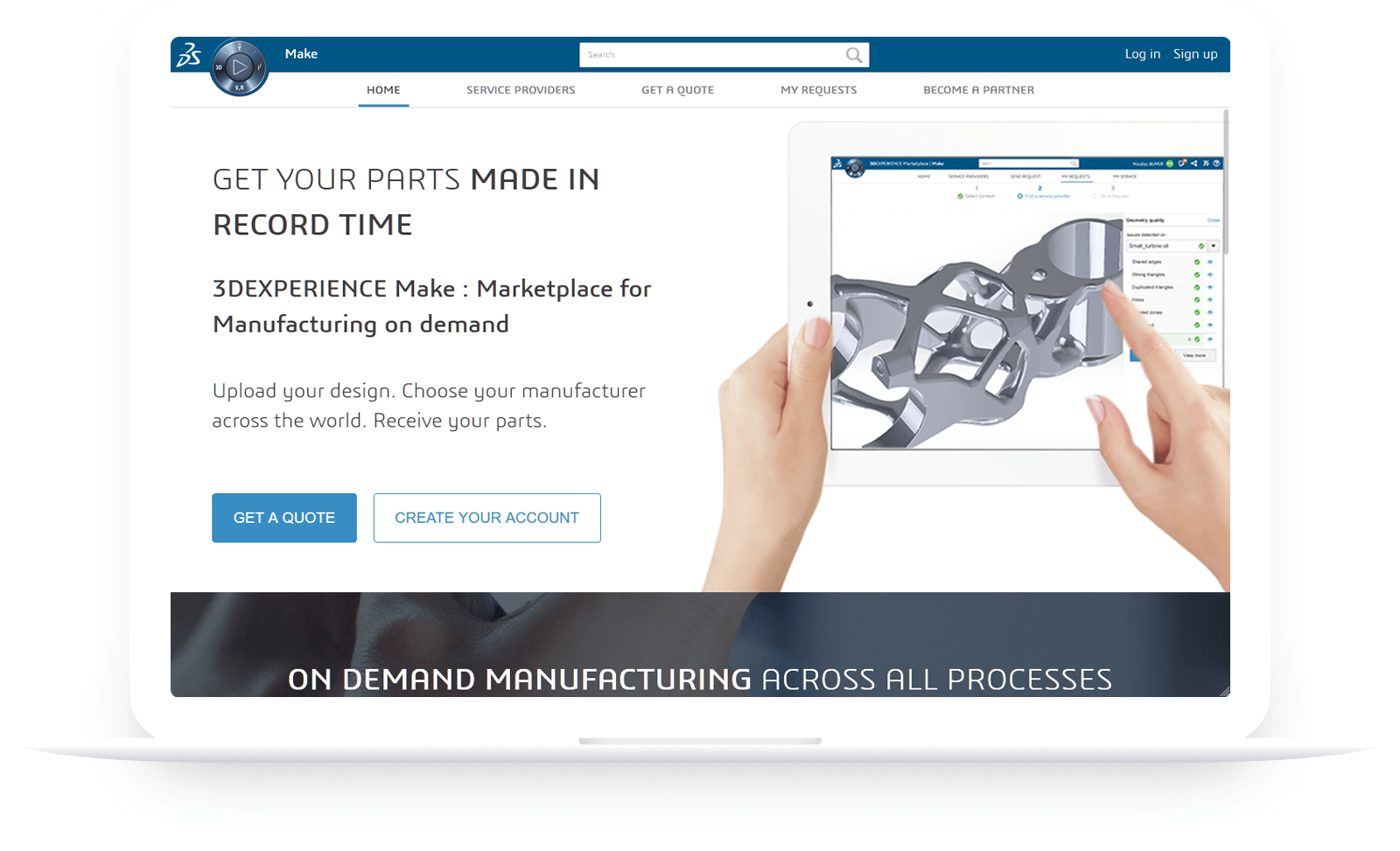

About 3DEXPERIENCE Make Online 3D Printing Service

The 3DEXPERIENCE Marketplace Make platform by Dassault Systèmes groups all of these steps together to provide a comprehensive view of what's available in terms of technologies, materials, finishes, certifications, and lead times, with instant quotes based on your design.

Get multiple quotes for your parts in seconds