Wax manufacturing

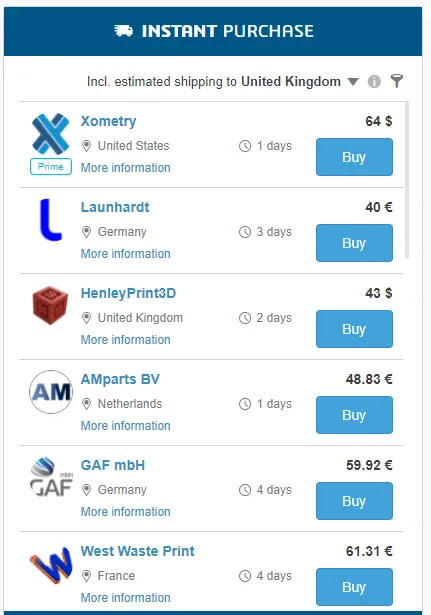

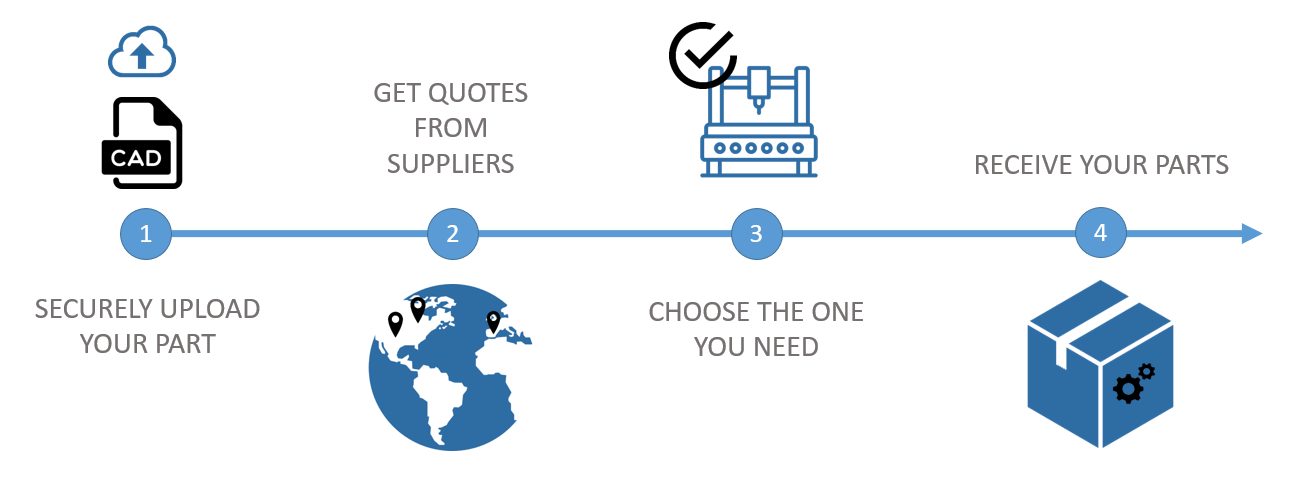

Upload your design, get your wax manufacturing quote, choose your manufacturer and receive your parts!

SECURE PAYMENTS

Via payment card or purchase order

PROTECTED IP

Your data is confidential and secure with us. Use your own Non Disclosure Agreement

INSTANT QUOTE

For 3D Printing and CNC Machining, get quote in few seconds.

Wax manufacturing with 3DEXPERIENCE Make

3DEXPERIENCE Make is an On-Demand Manufacturing platform, which connects designers or engineers with industrial service providers. Our service providers are mostly based in North America (United States and Canada) and in Europe (United Kingdom, France, Netherlands, Germany etc...). We currently offer wax manufacturing for 3D printing processes.

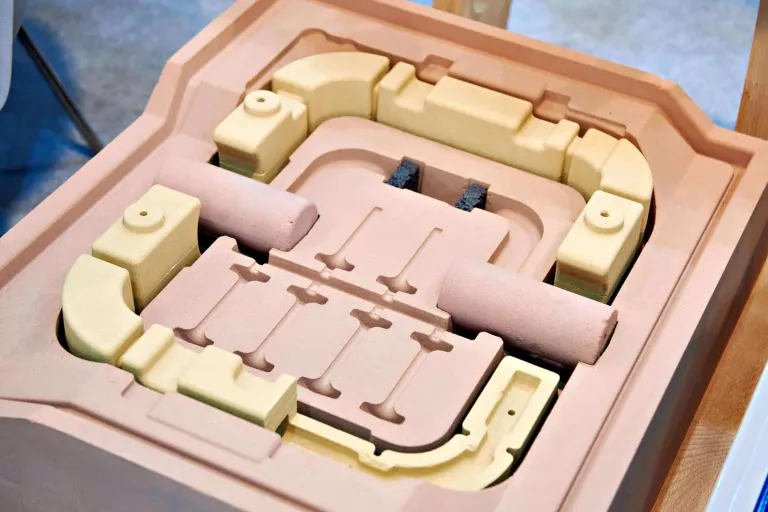

In manufacturing processes, wax materials are often used for their easy-to-remove properties. Wax has the property of burning with very low residues, making it perfect for investment casting, also called lost wax casting.

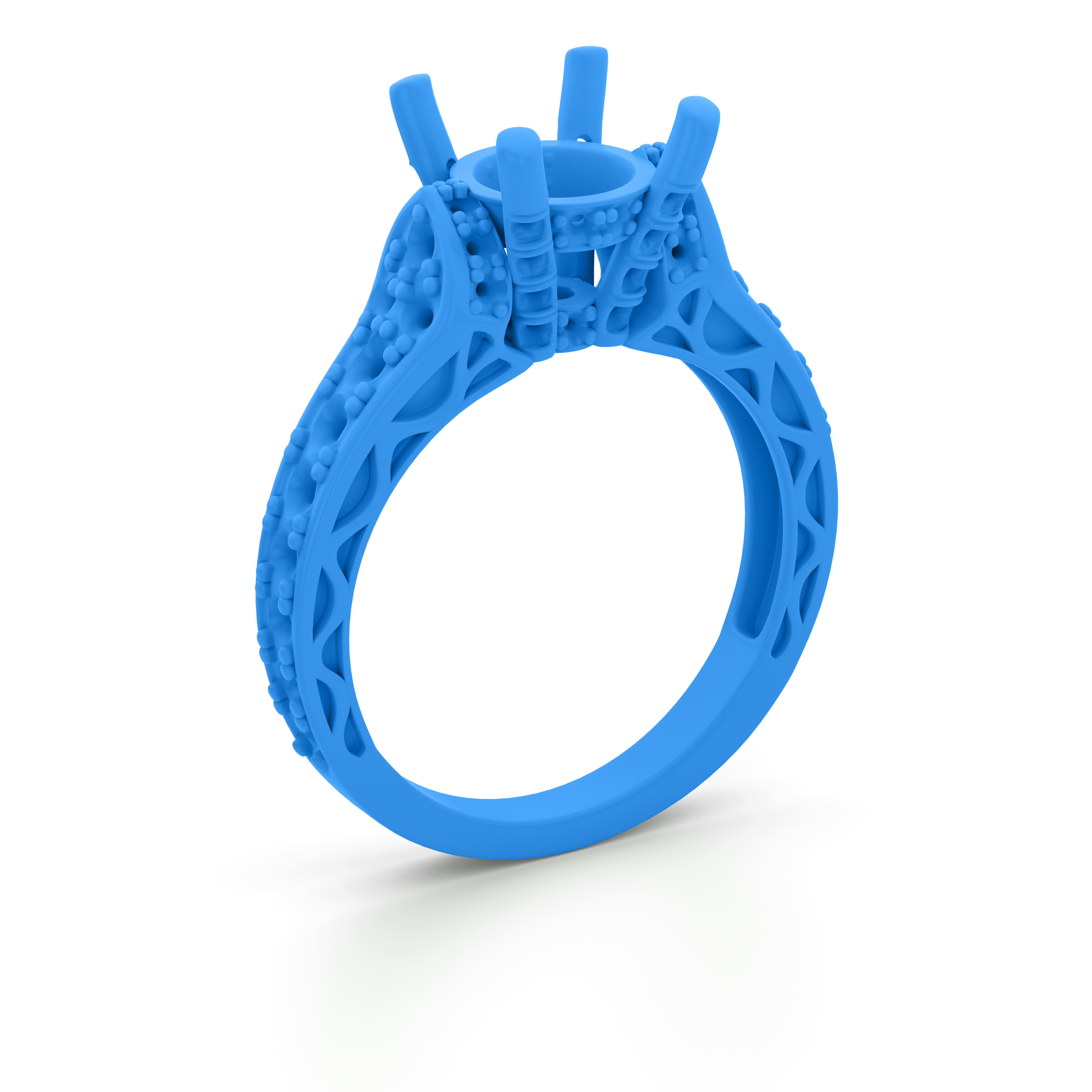

Our wax manufacturing network of service providers are capable of handling a high versatility of projects in Health with for example dental molds and 3D printed Jewelry.

Thanks to our powerful algorithm, you can get quotes in seconds for your wax project from dozens of manufacturing providers.

Online manufacturing service: how does it work?

Features to help you

Check & repair or Geometry check is a feature that helps you to understand Geometry issue of your part and could repair it live and online.

Check & Repair

Check & repair or Geometry check is a feature that helps you to detect geometry issue on your part and repair it online and live.

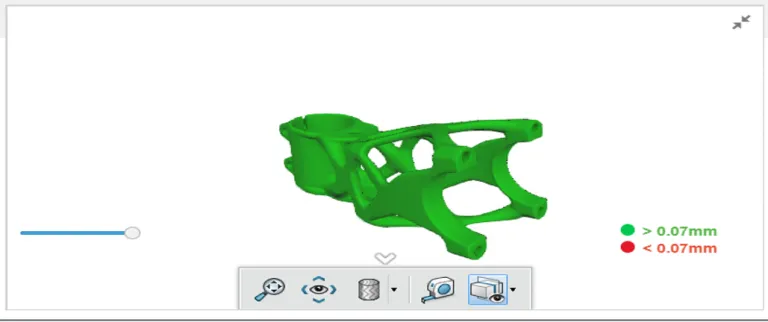

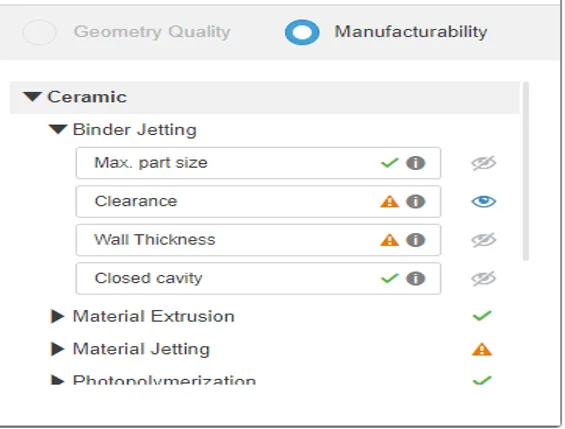

Manufacturability Check

This feature is available only for 3D Printing service. It helps you check the manufacturability of your part, depending on the materials and the process.

Instant quote engine

Receive in seconds several quotes thanks to our instant quote engine.

What is wax ?

Wax is the name of a broad collection of organic substances that are malleable, water repellent (hydrophobic) solids at room temperature. Most waxes are not a single compound but are a complex blend of different ingredients.

Waxes can be categorised into three groups depending on where they came from – natural (plants and animals), mineral (fossil fuels) and synthetic (made by humans).

Wax has many diverse uses, including objects made from it like candles and crayons; products that contain it such as polish, paint and lipstick; and materials coated in it such as paper and cheese.

A layer of wax is often added to the bottom of skies, snowboards, surfboards and drawer slides to reduce frication, and it is still widely used as a mold release agent in mold making.

FAQ Wax manufacturing

Discover our other materials for manufacturing

Metal

Aluminium, 316/316L, Steel, Stainless Steel, Tool Steel, Nickel, Titanium...

Plastic

ABS, POM(Acetal/Deltin), PEEK, PTFE, HDPE, PEI, PC, PP, etc...

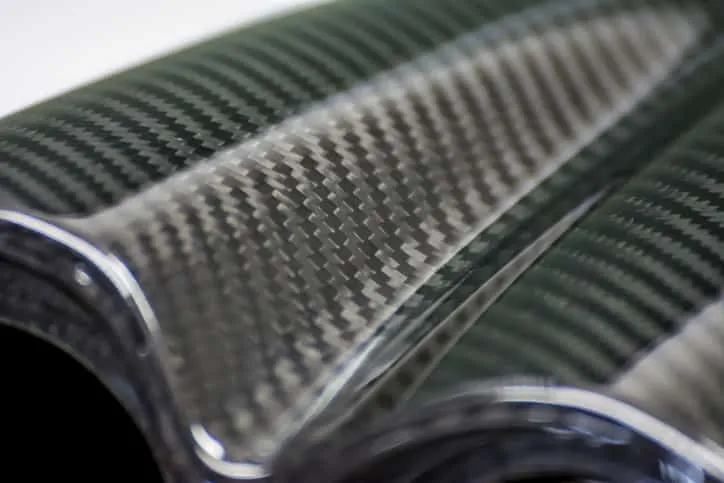

Composite

PA Glass, PA Aluminium, Plastic Kevlar, ABS Carbon Fiber, etc...

Sand

Get multiple quotes for your parts in seconds