Plastic manufacturing

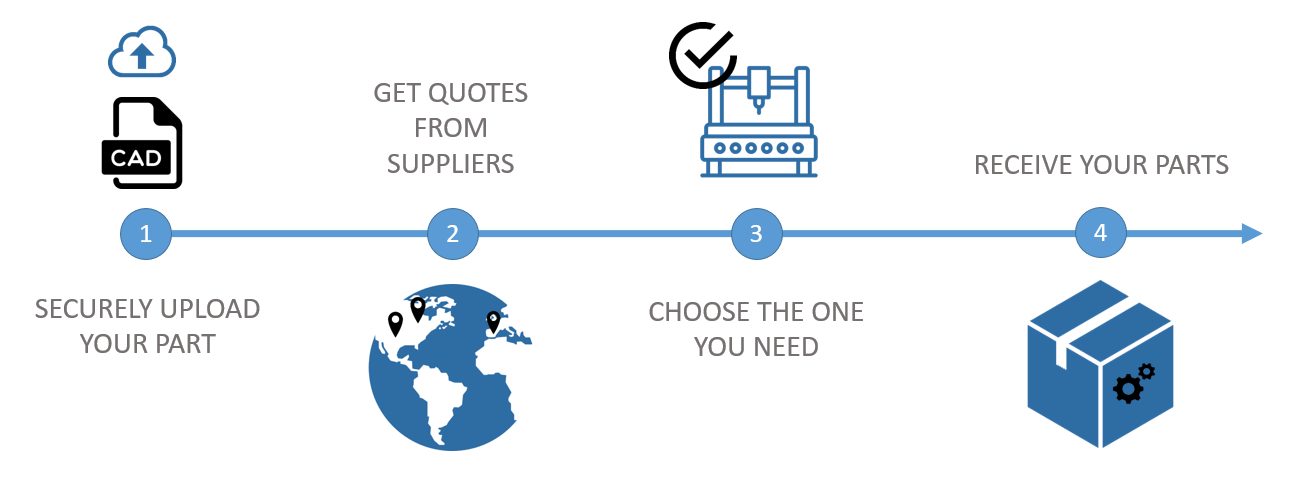

Upload your design, get your plastic manufacturing quote, choose your manufacturer and receive your parts!

SECURE PAYMENTS

Via payment card or purchase order

PROTECTED IP

Your data is confidential and secure with us. Use your own Non Disclosure Agreement

INSTANT QUOTE

For 3D Printing and CNC Machining, get quote in few seconds.

Plastic manufacturing with 3DEXPERIENCE Make

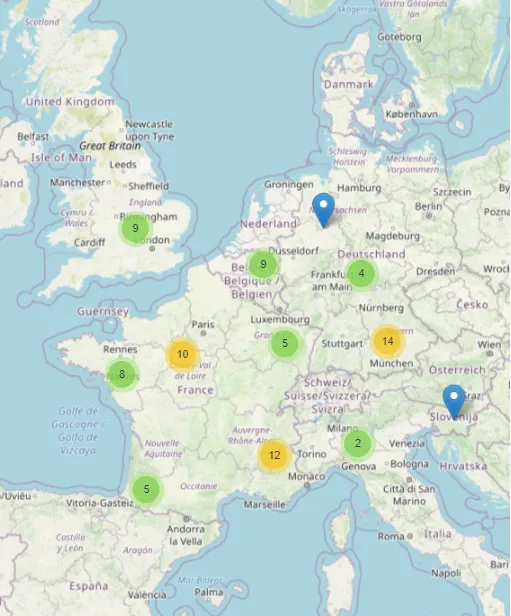

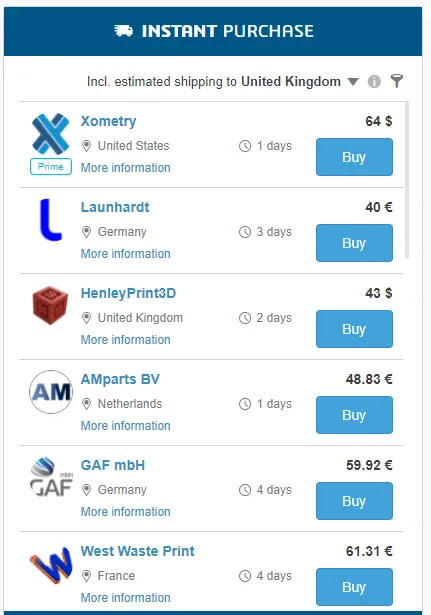

3DEXPERIENCE Make is an On-Demand Manufacturing platform, which connects designers or engineers with industrial plastic manufacturing service providers. Our service providers are mostly based in North America (United States and Canada) and in Europe (United Kingdom, France, Netherlands, Germany etc...). We offer plastic manufacturing options accross multiples processes such as 3D printing, CNC machining, Laser cutting and Injection molding.

Plastic manufacturing is well suited for Mockup or Prototyping thanks to the lower cost of plastic versus other materials.

Thanks to our powerful algorithm, you can get quote in seconds for your plastic manufacturing project from dozens of plastic manufacturing providers.

Our plastic manufacturing network of service providers is handling projects in various industry such as Aerospace & defense, Business Services, Construction, Consumer goods & retail, Energy & Materials, High-Tech, Home & Lifestyle, Industrial Equipment, Life Sciences & Healthcare, Marine & offshore, or Transportation & Mobility.

Our network of service providers offers dozen of plastic materials for your project. They can be classified as Acrylics, Polyesters, Silicones, Polyurethanes, Halogenated plastic and a few generic plastic materials that we offer include PA12, ABS, PLA, PET etc...

Discover How 3DEXPERIENCE Marketplaces Boost Your Design to Manufacturing Process

You’re in good company. Thousands of leading companies from all industries use our solutions.

Our network of Plastic manufacturing providers

United States

Canada

United Kingdom

France

Germany

Netherlands

and many more...

Online manufacturing service: how does it work?

Plastic materials available with our service providers

Plastic materials for 3D printing processes

- ABS

- PLA

- PET

- TPU

- ASA

- PEI

- PC

- UV CURABLE

- PA

- PP

Plastic materials for molding manufacturing

- ABS

- ABS PC

- HDPE

- LDPE

- PA

- PC

- PEEK

- PEI

- POM

- PP

- PS

- PVC

- TPE

- TPU

Plastic materials for CNC machining

- ABS

- POM ( acetal/delrin)

- PEEK

- PFTE

- HDPE

- PEI

- PC

- PP

What are the plastic manufacturing processes available at 3DEXPERIENCE Make?

Features to help you

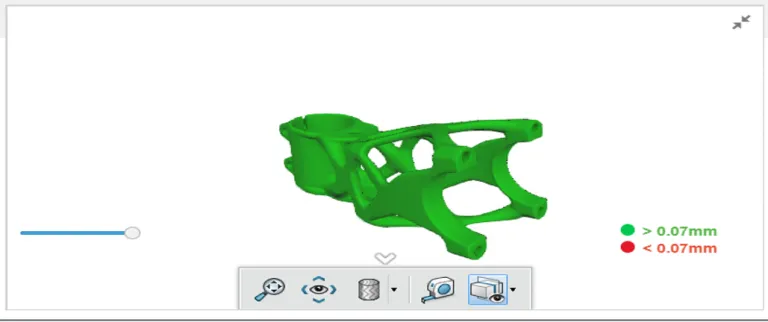

Check & repair or Geometry check is a feature that helps you to understand Geometry issue of your part and could repair it live and online.

Check & Repair

Check & repair or Geometry check is a feature that helps you to detect geometry issue on your part and repair it online and live.

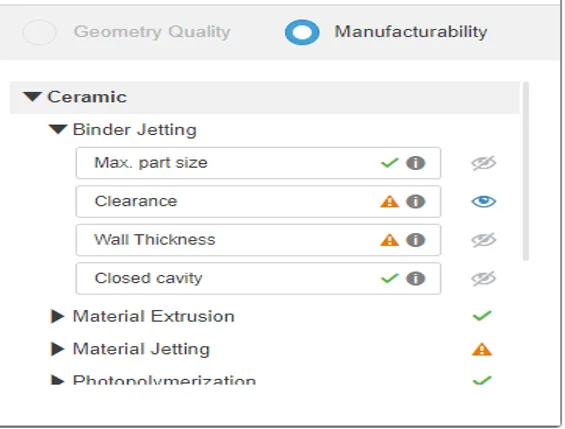

Manufacturability Check

This feature is available only for 3D Printing service. It helps you check the manufacturability of your part, depending on the materials and the process.

Instant quote engine

Receive in seconds several quotes thanks to our instant quote engine.

What is plastic manufacturing

Plastic is a material consisting of any of a wide range of synthetic or semi-synthetic organic compounds that are malleable and therefore can be molded into solid objects. Plasticity is the general property of all materials that involves permanent deformation without breaking. Polymers’ name is derived from their flexible and plastic properties.

Plastics are typically organic polymers of high molecular mass, but they often contain other substances. They are usually synthetic and most commonly derived from petrochemicals. However, today’s focus on the environment has led to a growing number of plastics to be derived from renewable materials such as polylactic acid from corn or cellulosics from cotton linters.

Plastics have been adopted in a significant, and ever-expanding, range of products thanks to their relatively low cost, ease of manufacture, versatility, and imperviousness to water. They can be found in products as simple as paperclips or as complex as planes.

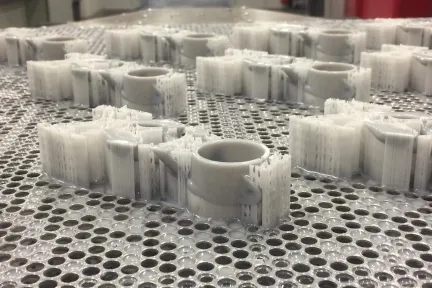

A large source of diverse plastic material is available across a widespread manufacturing spectrum such as 3D printing, CNC Machining, Polymer casting, Rotational molding, Vacuum forming, Injection molding, Extrusion, Blow molding. One of the most recent and exciting manufacturing domains is in 3D Printing. As new applications for 3D Printing are discovered almost daily, a diverse array of plastic objects have already been produced using the 3D Printing process. These objects can be found in prototyping labs, toys, mechanical gearboxes, medical prosthetics, and many more.

Plastics are generally classified by the chemical structure of the polymer's backbone and side chains; some important groups in these classifications include: Acrylics, Polyesters, Silicones, Polyurethanes, Halogenated plastics.

Questions People ask about Plastic manufacturing

What is plastic?

Plastic is the name given to a vast collection of materials that can be molded into an ever-expanding list of shapes, colours and sizes.

Products made entirely from plastic, or containing plastic components, surround us. Examples span simple items such as paperclips all the way to complex feats of engineering such as space satellites.

Plastic gained this popularity by being relatively low cost, versatile, easy to work with, durable, moldable and water-resistant.

Plastics consist of a wide range of synthetic or semi-synthetic organic compounds, with the main element being long molecule chains called polymers. These polymers give plastic the strength and flexibility to be formed into solid objects.

What are the common types of plastic?

Scientists and chemical engineers have spent the past 100 years developing a broad range of different plastics. These are generally grouped together by the chemical structure of their primary polymer.

Some of the most important groups include:

- Acrylics

- Polyesters

- Silicones

- Polyurethanes

- Halogenated plastics

The most frequently used plastics are:

- Acrylonitrile Butadiene Styrene (ABS) – applications include protective outer cases for electronics and electrical equipment, automotive trim components, LEGO bricks and pipes and pipe fittings. It is also widely used as a material for 3D printing (see What are the plastic materials used in 3D printing?)

- Polyamide (PA) – occurs both naturally, for example in wool and silk, or synthetically as nylons. Applications include textile fibers, toothbrush bristles, tubing, fishing line and low-strength machine parts.

- Polycarbonates (PC) – a tough material used to manufacture compact discs, eyeglasses, riot shields, security windows, traffic lights and lenses.

- Polyester (PES) – found extensively in the clothing and textile industries.

- Polyethylene (PE) – the most common plastic, mainly used in the packaging sector for bags, films and containers. Sometimes referred to as polythene for certain applications.

- High-density polyethylene (HDPE) – Often used in molded bottles, cases, plastic lumber, and piping.

- Low-density polyethylene (LDPE) – widely used in outdoor furniture, floor tiles, shower curtains and clamshell packaging.

- Polyethylene terephthalate (PET) – the most common thermoplastics polyester polymer, with applications include clothing fibers and containers for liquids and foods.

- Polypropylene (PP) – applications include automotive components, packaging, labelling, textiles, stationary, reusable containers and polymer banknotes.

- Polystyrene (PS) – used to make foam packaging peanuts, food containers and disposable tableware.

- High-impact polystyrene (HIPS) – commonly used to manufacture toys, refrigerator liners, food packaging and vending cups.

- Polyurethane (PUR and PU) – the most common plastic found the automotive industry. Other uses include cushioning foams, thermal insulation forms, surface coatings and printing rollers.

- Polyvinyl chloride (PVC) – common applications for rigid PVC (RPVC) include plumbing pipes, gutters, doors, windows and bank or membership cards. Flexible PVC (FPVC) is used for shower curtains, flooring, imitation leather, inflatable product and as a replacement for rubber.

How is plastic made?

Whether derived from petrochemicals or biological material, the process to make plastic involves five steps:

- Extraction

Raw ingredients are removed from either petroleum (crude oil), natural gas and coal or renewable feedstock such as plant starch or sugar cane. The extracted material contains many different compounds which need to be split apart and separated from each other.

- Refining

Heating the material converts it into different monomers (molecules), making it easier to separate out the useable elements from impurities and contaminants. In the case of petroleum, these monomers include liquid fuels, lubricants, petrochemicals and naphtha, a key ingredient in the manufacture of plastic.

- Polymerization

A combination of heat and pressure is then used to chemically bond chains of these monomers together to create polymers, the building blocks of all modern plastics.

- Compounding

Additives are blended with the polymers to create plastics with different strengths and applications. UV-stabilizers, for example, are added to protect the plastic in a similar way to how sunscreen protects skin. Other additives include glass fibre to add strength, or chemicals to enable the plastic to breakdown and biodegrade.

- Extrusion

The last step is to mechanically extrude, or squeeze out, this molten mixture, usually in long tubes or sheets. These are then broken up into sheets or pellets of different shapes, sizes and colors depending on their intended end-use, and shipped to manufacturers to be transformed into countless products.

What are the main manufacturing processes for plastics?

The techniques used in plastic manufacturing vary, but almost all start with heating the plastic sheets or pellets. The most common processes include:

- Extrusion – this is a very similar process to how plastic itself is made. Plastic pellets are heated inside a temperature-controlled barrel and forced through a metal die by a mechanical screw. Cooling the plastic as it emerges fixes the shape and allows it to be cut to the desired length.

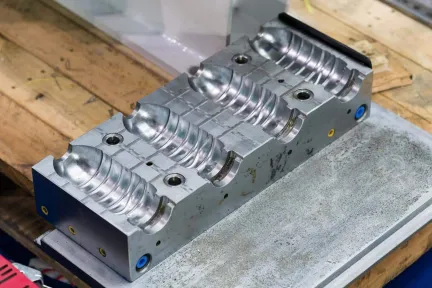

- Injection molding – heated pellets are melted and injected via a screw into a temperature-controlled mold cavity. The mold is then clamped and cooled in order for the plastic to harden into its final shape. This process is ideal for high volume manufacturing as it can produce many items in a short space of time. It can be used to create small parts such as bottle caps or large items such as automobile bumpers and wheelie bins.

- Injection blow molding – this is similar to injection molding, but uses compressed air to force the molten plastic into the mold cavity. This technique enables the manufactured object to be hollow, rather than solid.

- Rotational molding – similar to injection blow molding in that it produces a hollow object. The difference is that the mold is spun once filled, using centrifugal pressure to force the plastic into the cavity rather than air. Objects made using this technique can lack the refinement of those made by injection blow molding.

- Thermoforming – this involves heating a plastic sheet until pliable and then stretching the softened material over a mold so it conforms to the shape. For more complex shapes, a vacuum inside the mold can be used to suck the material tightly to the form. This is known as vacuum forming. Both thermoforming and vacuum forming are capable of producing many objects very quickly.

What are the benefits of plastic?

Plastic is so prevalent because it provides several key advantages:

- Versatility – There are numerous types of plastics, each with its own unique set of properties.

- Manufacturability – plastic is easy to work with and can be quickly molded into shapes of different sizes, colours and transparency.

- Durability – Depending on how they're manufactured, plastics can be very tough, hardwearing and resistant to water and chemicals. Their strength can be further increased by mixing in additives such as glass or carbon fibers.

- High strength to weight ratio – substituting heavier metal or glass items with plastic can significantly reduce distribution costs, in the case of food and beverage containers, or increase the fuel economy of a vehicle.

- Low cost – Despite having a relatively complicated manufacturing process, plastic is easy to mass-produce, making it affordable and convenient.

- Recyclability – the list of plastics which can be made into new products continues to grow, although some of the processes involved aren’t yet widespread.

What are the limitations of plastic?

Plastics do have a number of downsides that are worth noting:

- Non-renewable sources – the vast majority of plastics manufactured today are derived from finite resources such as crude oil, natural gas or coal.

- Single use – much of the plastic currently in use is designed to be used once and discarded. If not properly disposed of, such as being collected for recycling, the material is likely to remain in the environment for hundreds of years.

- Reprocessing costs – the cost of recycling some types of plastic is very high and the process can require complicated sorting and cleaning systems. Additionally, plastics can usually only be recycled a handful of times before the quality becomes too poor for use. Whereas, a material like glass or aluminium doesn’t degrade during the process, so can be recycled an infinite number of times.

- Low melting point– many plastics have relatively low melting points which makes them unsuitable for use at high temperatures.

- Flammability – Plastics which contain carbon and hydrogen in their polymer molecules are often highly volatile. They burn quickly and release toxic gases which can be explosive and serve as an accelerant.

Discover our other materials for manufacturing

Get multiple quotes for your parts in seconds