Injection Molding SPI Surface Finishes

SPI surface finishes are the most common set of injection molding finishing standards around the world. With over 12 different grades, part designers have many options to choose from.

Introduction to injection Molding SPI Surface Finishes

Parts manufactured with injection moldings very often need finishing to meet the requirements for end use. The good news is that there are a wide range of surface finish options available for injection molded parts. These surface finishes have an impact on the aesthetic and texture of the part. For these reasons, surface finish is a very important design consideration for part engineers and designers.

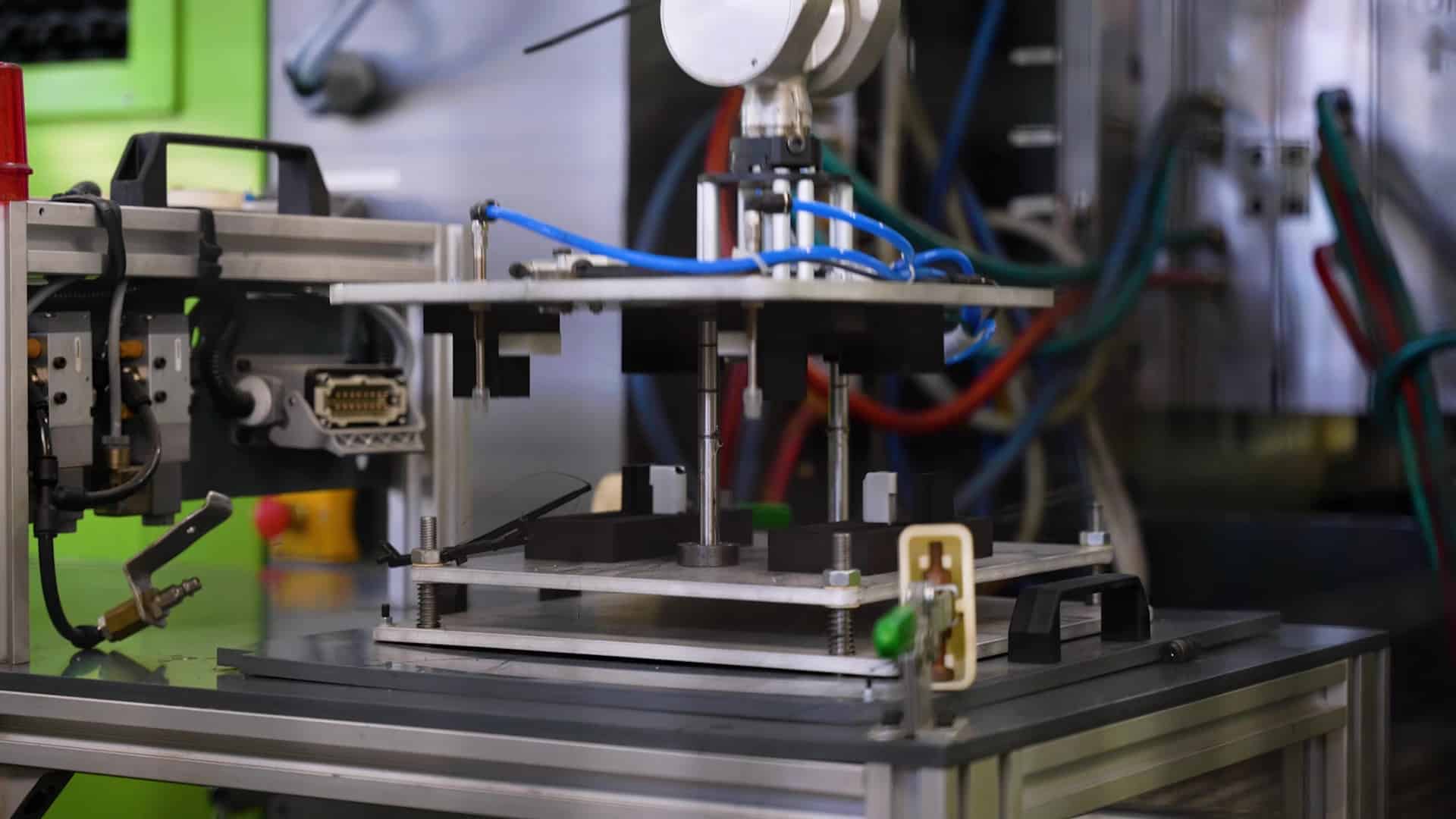

Molds are most often machined using aluminum or steel material. As a result, the molded part will receive tiny surface imperfections from the metal molds. In other words, these tiny marks left on the molds from the mills will show up on the surface of the molded part unless they’re removed by polishing or bead blasting.

Moreover, most molds are finished to varying degrees, but the more finishing that takes place, the more mold tooling that will be required. The result is an increase in cost and lead times for producing the mold. For these reasons, surface finishes are extremely important for injection molded parts.

What are SPI Surface Finishes?

SPI surface finishes are the generally accepted surface finish standards set by the Plastics Industry Association (SPI) worldwide. These standards cover 12 different grades of SPI mold finishes. It’s worth noting that the terms “SPI surface finishes” and “SPI mold finishes” are used interchangeably.

Let’s take a closer look at the 12 different injection molding SPI surface finishes and their corresponding optimal materials.

What’s the Right Material for Each SPI Surface Finish?

- SPI Surface Finish A-1 - Acrylic

- SPI Surface Finish A-2 - Acrylic, PC

- SPI Surface Finish A-3 - ABS, Acrylic, PS, Nylon, PC

- SPI Surface Finish B-1 - ABS, Acrylic, PP, PS, HDPE, Nylon, PC

- SPI Surface Finish B-2 - ABS, Acrylic, PP, PS, HDPE, Nylon, PC

- SPI Surface Finish B-3 - ABS, Acrylic, PP, PS, HDPE, Nylon

- SPI Surface Finish C-1 - ABS, Acrylic, PP, PS, HDPE, Nylon, TPU

- SPI Surface Finish C-2 - ABS, Acrylic, PP, PS, HDPE, Nylon, TPU

- SPI Surface Finish C-3 - ABS, Acrylic, PP. PS, HDPE, Nylon, TPU

- SPI Surface Finish D-1 - ABS, PP, PS, HDPE, Nylon, PC, TPU

- SPI Surface Finish D-2 - ABS, PP, PS, HDPE, Nylon, TPU

- SPI Surface Finish D-3 - ABS, PP, PS, HDPE, Nylon, TPU

What’s the Best SPI Surface Finish for Your Injection Molded Part?

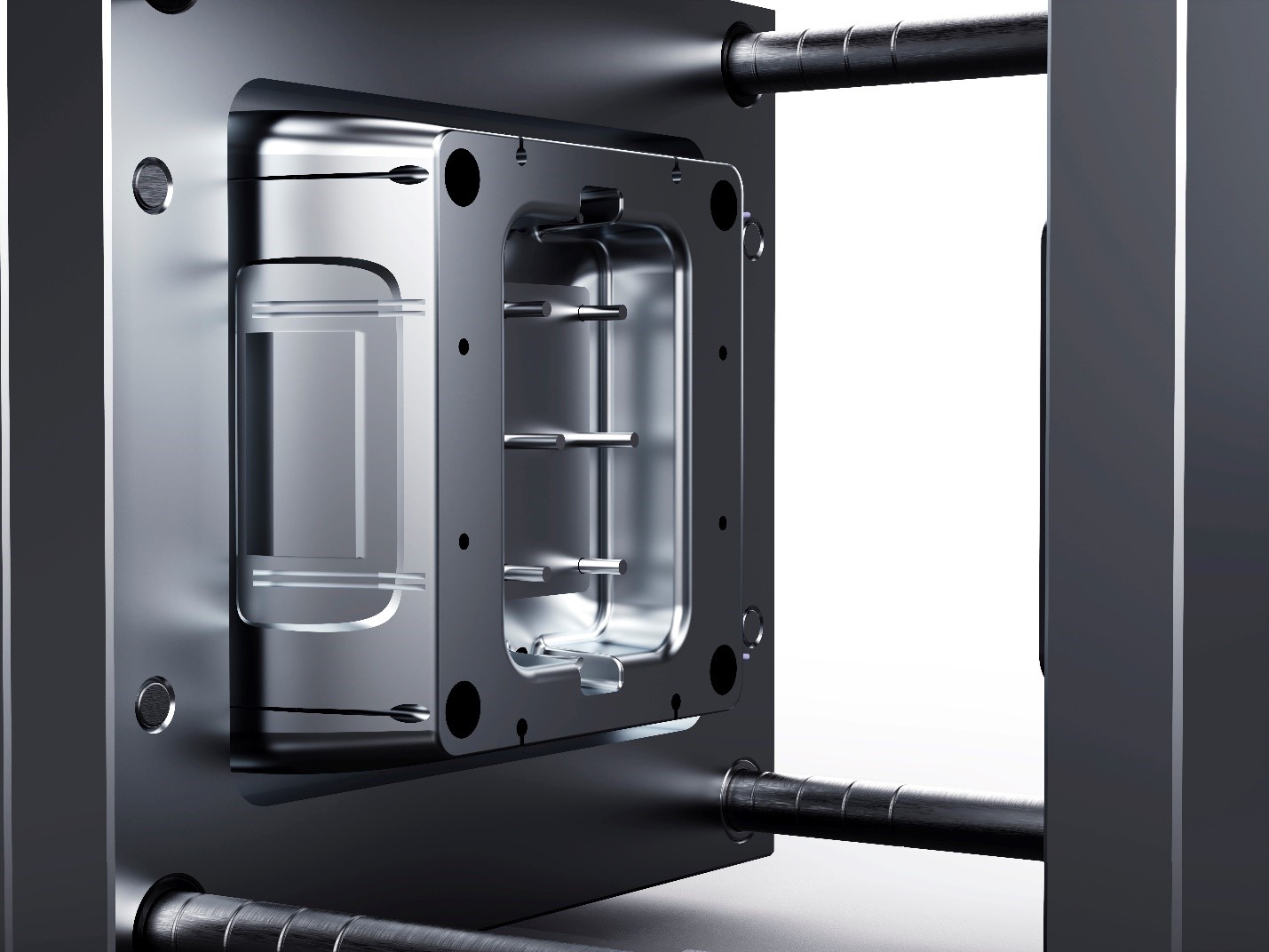

The reality is surface finishes on injected molded parts are different from the surface finishes of 3D printed or CNC machined parts. With 3D printed and CNC machined parts, surface finishing takes place after the part is manufactured. However, with injection molded parts, the surface of the mold itself is prepared or textured so that the part comes out of the mold finished. Therefore, if the intended part design calls for a matte finish, the inside of the mold is textured accordingly so that the part comes out of the mold with a matte finish.

On this basis, part designers can better understand which SPI surface finish is going to be the best for their injection molded part. For designers who need parts that are more visually appealing, they can texture the inside of the mold to meet their aesthetic parameters. For example, a resulting matte or smooth texture on the part’s surface gives a more desirable aesthetic and hides small imperfections such as knit lines, flow lines, shadow marks, and sink marks that were caused by the mold. For many consumers, products with eye-catching surface finishes are more desirable.

In addition to the aesthetic factors, part designers can help decide which SPI surface finish is best for their part when it comes to functionality. For example, textured surface finishes can increase paint and sticker adhesion. In fact, a matte surface texture can hold paint longer and ensure that labels adhere to products longer. Moreover, textured surface finishes on injection molded parts can improve the end user’s ability to better grip the part, which can be a very desirable functional characteristic.

What is the VDI 3400 Standard?

Even though SPI surface finish standards are widely used across the world, they aren’t the only mold finishing standards. Another finishing standard worth noting is the VDI 3400 texture or surface finish standard. VDI 3400 is determined by the Society of German Engineers, and it covers 45 different grades of texture for parts manufactured with injection molding.

Get multiple quotes for your parts in seconds