5-Axis CNC Machining Service

5-axis CNC machining is a powerful manufacturing solution for producing parts with complex features and geometries because of the two additional axes that are introduced.

Introduction to 5-Axis CNC Machining Service

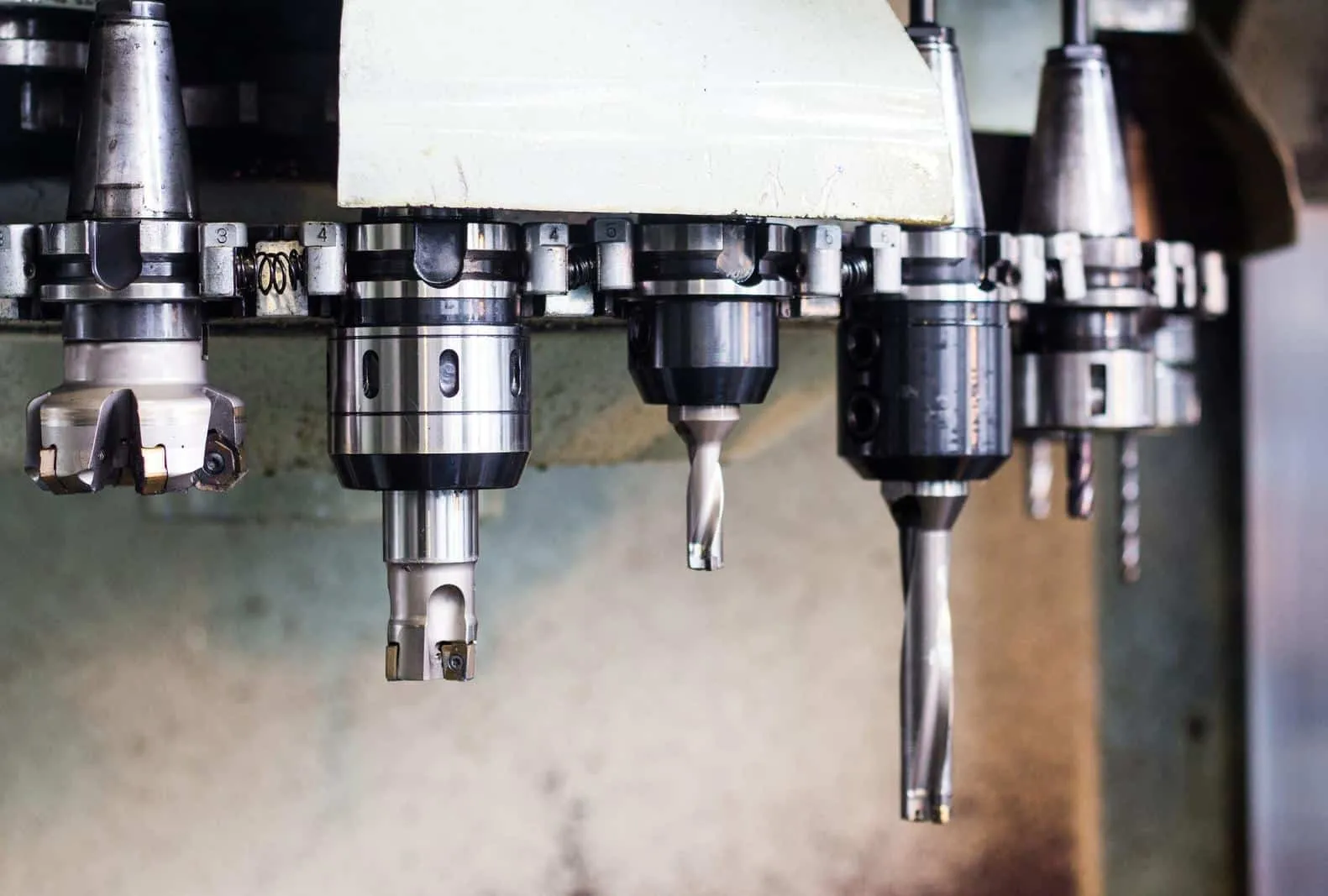

CNC machining is a subtractive manufacturing method that removes material using computer-controlled, precision machines with a wide range of cutting tools to achieve an intended design. CNC machines come in three main kinds including horizontal milling machines, vertical milling machines, and lathes.

CNC machines are highly effective manufacturing solutions because they use pre-programmed computers to determine precise movements of the tools. These programs operate based on instructions that are entered into the CNC machine using encoded CAM (computer-aided manufacturing) software.

5-axis CNC machines have two additional axes compared to traditional 3-axis machines. With a 5-axis machine, the cutting tool can cut the part along five directions instead of three. These additional axes provide increased movement and rotation during manufacturing. Let’s take a closer look at the 5-axis CNC machining service.

Advantages of 5-Axis CNC Machining

5-axis machining offers the unique of advantage of the fact that the mill and the part can be moved in as much as 5 ways at the same time around multiple axes. As a result, 5-axis machining enables complex parts to be produced in a cost-effective manner.

Here is a closer look at the advantages of 5-axis CNC machining:

- Reduced number of setups. 3-axis machining requires multiple setups to achieve the desired geometry by manually rotating the part if it requires machining on multiple faces. With a 5-axis machine, fewer setups are required to manufacture a part with complex geometry.

- Can avoid the need for complex fixtures. Complex fixtures must often be used to hold the part in its required orientation during 3-axis machining. As a result of two additional axes, 5-axis machining allows manufacturers to avoid creating these fixtures since the workpiece is held at one location on the part and rotated to produce the geometry.

- Increased efficiency of material removal. 5-axis machining enables the cutting tool to be tangential to the cutting surface. As a result, shorter cycle times and lower costs are possible since an increased amount of material is removed with each pass of the cutting tool.

- Superior surface finishes. During 3-axis machining, lots of smaller cuts must be done to produce a desired surface finish, which adds on costly lead time. In contrast, since 5-axis machines are superior on contoured geometries, a far better surface finish can be produced.

Applications of 5-Axis CNC Machining

5-axis CNC machining is able to manufacture parts with complex features with a high degree of efficiency. For these reasons 5-axis machining is often utilized for manufacturing parts that are used in many different industries. Here are a some of the most common applications that use 5-axis CNC machining:

- Aerospace. Aerospace components often have shapes that are highly intricate. For this reason, 5-axis machining is a great manufacturing option because of its superior precision.

- Medical. 5-axis CNC machining is often used to produce a wide range of implants, devices, and other types of medical equipment because of their demand for high levels of precision to meet strict medical compliance standards.

- Defense. The defense industry leverages 5-axis CNC machining to make many different essential parts for applications such as high-performance engine components, submarine parts, turbine blades, advanced weaponry, and more.

- Oil and Gas. The energy sector, including oil and gas, often benefits from the precision manufacturing offered by 5-axis machining. Oil and gas equipment often involves the use of materials that are difficult to machine. With 5-axis machining, materials with lower machinability properties can still be efficiently machined for this industry.

What are the 5 Axes on a CNC Machine?

5-axis machines add to the three linear axes on traditional 3-axis machine by tilting and rotating the table holding the workpiece. These two additional rotational axes are called the tilting table axis (A-axis) and the table rotation axis (B-axis).

In total, 5-axis machines use five different directions (or axes) commonly called X, Y, Z, A, and B. The G-code instructions for the 5-axis CNC machine control the movement of the cutting tools along the X, Y, and Z axes and the motion of the worktable along the A and B axes to manufacture the intended part designs.

Here is a summary of the 5 axes:

- X - Left to right

- Y— Front to back

- Z— Top to bottom

- A— Titling table

- B — Table rotation

When Does 5-Axis Machining Make Sense?

As a result of the extra axes, up to five faces of a part can be machined in just one operation. These qualities make the process extremely efficient and precise. For these reasons, 5-axis machines are ideal for parts that include complex movements and intricate geometries that would otherwise require lots of setups. As part designers create increasingly complex parts, they require at least five different faces to be machined, which means that 5-axis machining is increasingly a go-to solution for CNC manufacturing.

Compared with traditional 3-axis machining, 5-axis CNC machining allows the workpiece to be worked on five axes rather than just three. Although traditional 3-axis machining is still versatile and useful for certain projects, 5-axis machining is superior for parts that have more complex designs. That being said, if only one flat surface needs cutting, 3-axis machines could be the best option in terms of affordability. Moreover, 3-axis machines are easier to program, so the cost of using expert CNC programmers is removed.

Can 5-Axis Machining Provide Tight Tolerances?

5-axis CNC machines provide high levels of accuracy and geometric precision. Not only do they achieve these accuracy levels when machining deeper parts and hard-to-machine materials, but they can also meet very strict tolerance requirements.

Since 5-axis machines provide an amazing amount of movement and flexibility, they are much more precise and able to meet tight tolerances compared to other manufacturing methods. For these reasons, 5-axis CNC machines are a great manufacturing solution for achieving tight surface profile tolerances on contoured surfaces with complex geometries.

Get multiple quotes for your parts in seconds