Rapid Prototyping Service

Online rapid prototyping services are game-changers for engineers who need to iterate their product designs quickly and cost-effectively.

SECURE PAYMENTS

Via payment card or purchase order

PROTECTED IP

Your data is confidential and secure with us. Use your own Non Disclosure Agreement

INSTANT QUOTE

For 3D Printing and CNC Machining, get quote in few seconds.

Rapid prototyping service with 3DEXPERIENCE Make

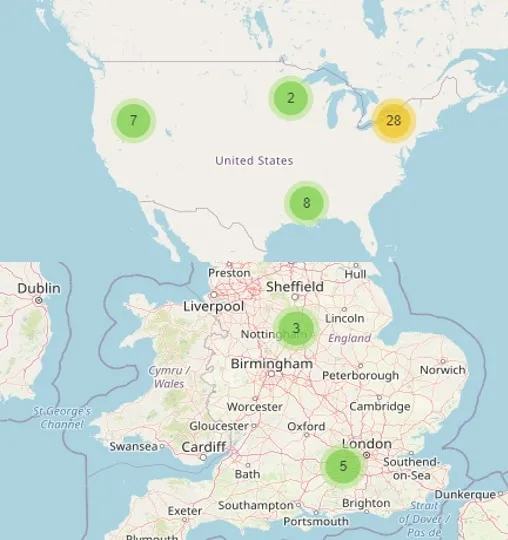

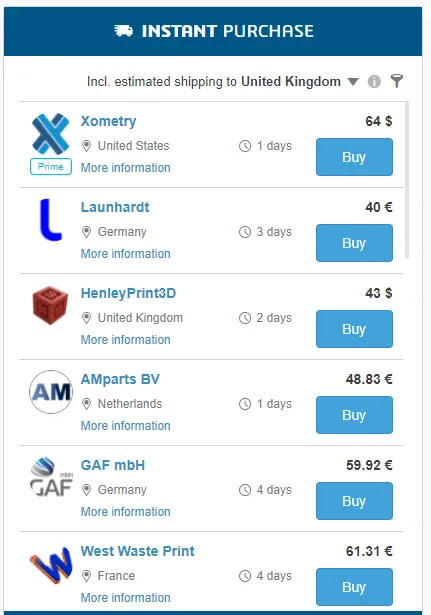

3DEXPERIENCE Make is an On-Demand Manufacturing platform, which connects designers or engineers with industrial Rapid prototyping service. Our service providers are mostly based in North America (the United States and Canada) and Europe (United Kingdom, France, Netherlands, Germany, etc.). Rapid prototyping service is today mostly used for Mockup or Prototyping (technical or presentation) and Small Series.

Our network of Rapid prototyping service providers offers hundreds of materials for your project, Plastic (PA12, ABS, PLA, PET, etc.), Metal (Stainless steel, 316, Aluminum, Titane, etc.), Ceramic, Wax, Sand or Composite (PA Glass, PA aluminum, ABS Carbon fiber, etc.) and various process as 3D Printing service, CNC Machining service, Cutting Service, Forming service, Injection molding service...

Our online rapid prototyping services

Discover How 3DEXPERIENCE Marketplaces Boost Your Design to Manufacturing Process

You’re in good company. Thousands of leading companies from all industries use our solutions.

Our network of Rapid Prototyping Services

Materials of our Online Rapid Prototyping Service Providers

Features to help you

Check & repair or Geometry check is a feature that helps you to understand Geometry issue of your part and could repair it live and online.

Check & Repair

Check & repair or Geometry check is a feature that helps you to detect geometry issue on your part and repair it online and live.

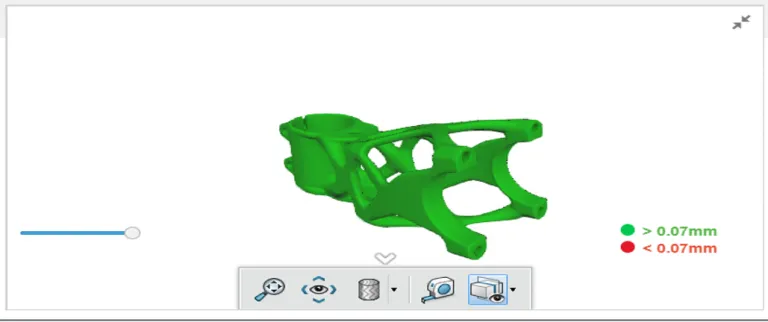

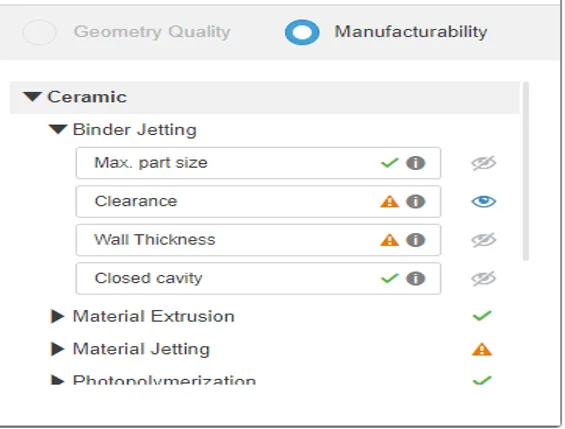

Manufacturability Check

This feature is available only for 3D Printing service. It helps you check the manufacturability of your part, depending on the materials and the process.

Instant quote engine

Receive in seconds several quotes thanks to our instant quote engine.

What is Rapid Prototyping Service and How Does It Work?

Rapid prototyping is an important phase of the development process for creating parts and products. By taking advantage of fast and affordable manufacturing methods, multiple iterations of a part or product can be easily generated for testing and analysis purposes.

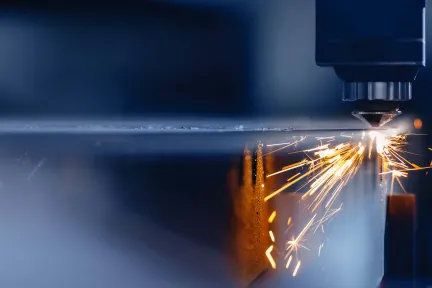

Multiple types of 3D printing processes are commonly used for rapid prototyping because of their cost effectiveness and extremely short lead times. In addition to 3D printing, other types of rapid prototyping processes include sheet metal fabrication, CNC machining, and rapid injection molding.

When it comes to rapid prototyping strategies, engineers often require multiple designs of a prototype to be manufactured at the same time or one prototype to be produced and revised very quickly until the prototype meets its intended specifications. Rapid prototypes give engineers key data points that helps them decide on any design modifications prior to generating more expensive models for further analysis or final production. In this sense, rapid prototyping reduces the risk of moving hastily into production without an adequate amount of confirmatory data.

The Different Types of Rapid Prototyping and Their Applications

The good news for part designers and engineers is that there is a wide range of viable manufacturing processes available when it comes to online rapid prototyping services. While there are many different options when it comes to which rapid prototyping process to use, engineers must decide which process and material would be the best for their specific prototype. A growing trend in rapid prototyping is the use of 3D printing technologies because these methods are very affordable and offer short lead times.

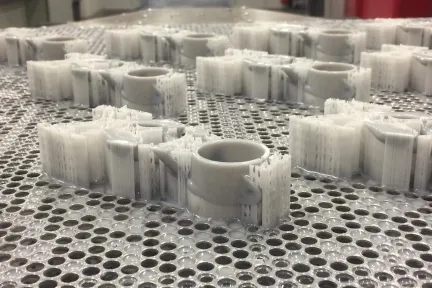

Rapid Prototyping Service Using 3D Printing

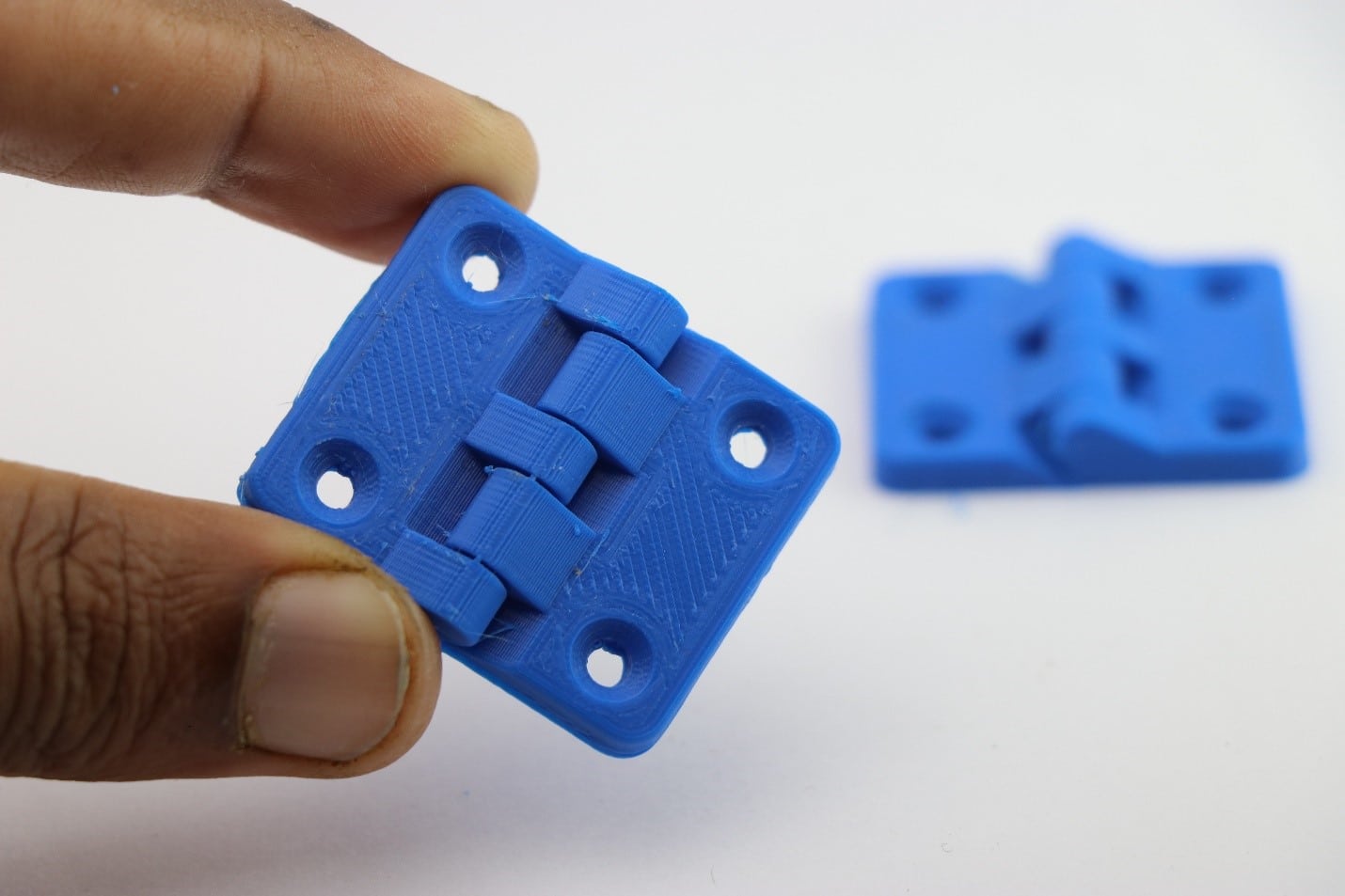

When it comes to rapid prototyping, 3D printing is one of the most common and effective manufacturing methods. What makes 3D printing immensely popular for rapid prototyping is that it’s cost-effective and fast.

Here is a closer look at the three most common 3D printing methods used for rapid prototyping: selective laser sintering (SLS), stereolithography (SLA), and fused deposition modeling (FDM).

- Selective Laser Sintering (SLS). SLS 3D printing is extremely versatile because of its balance of desirable mechanical properties, speed, high-resolution details, and affordability. As a result of this versatility, SLS 3D printing is a great option for rapid prototyping.

- Stereolithography (SLA). SLA 3D printing is notable for offering the best surface finishes of any 3D printing technology used in rapid prototyping. Moreover, SLA 3D printing provides a high level of accuracy and the ability to achieve tight tolerances.

- Fused Deposition Modeling (FDM). FDM is advantageous in rapid prototyping because you can use a wide range of thermoplastic material including ABS, ULTEM, and PC. Moreover, FDM 3D printing can quickly generate large prototypes in one piece.

Rapid Prototyping Service Using CNC Machining

CNC machining processes including turning and milling are excellent for rapid prototyping when parts need a prototype to be analyzed in its final material if cut from fully dense stock. Additionally, a wide range of plastics and metals can be used in rapid CNC machining.

When it comes to lead time, CNC machined prototypes can often be manufactured and distributed in less than a week. Despite this speed, 3D printed prototypes are still produced faster than CNC machined prototypes because of the extra machine set-up time required in CNC machining.

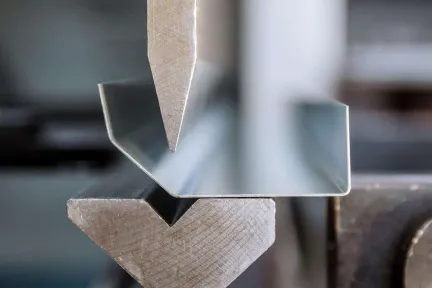

Rapid Prototyping Using Sheet Metal Fabrication

Rapid sheet metal fabrication is commonly utilized when producing quick-turn flat parts that need a prototype to be analyzed using the production metal material. These types of parts are turned around in one week or less. Moreover, rapid prototyping using sheet metal fabrication is so cost-effective that you can often fabricate two or more prototype designs in parallel.

While the most common sheet metal used in rapid prototyping is Aluminum 5052, there are also several different types of alloys that can be used including stainless steel, copper, and steel. While rapid sheet metal manufacturing offers lead times that are comparable to rapid CNC machined parts, the lead times are longer than 3D printed prototypes. Additionally, it’s important to keep in mind that sheet metal fabrication involves additional set-up time like CNC machining, whereas 3D printing does not.

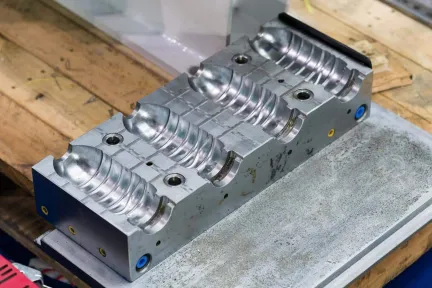

Rapid Prototyping Using Injection Molding

Rapid injection molding has the ability to produce highly durable sets of identical prototypes for testing purposes. Using plastic material, rapid injection molding offers both bridge tooling during product launches and also high-fidelity part evaluations.

Generally speaking, the lead time for rapid tooling with injection molding is two weeks for the initial parts. In many respects, rapid injection molding is the best solution for rapid prototyping compared to CNC machining or 3D printing because of stringent mechanical demands and material requirements that are oftentimes mandatory in those processes.

There’s no denying that rapid plastic injection molding is slower compared to CNC machining and 3D printing, but this shortcoming is compensated by its ability to produce prototypes in as close to the intended geometries as possible. In this sense, injection molding leads the way because of its ability to achieve superior repeatability and extremely accurate final forms.

Discover our other manufacturing services

Get multiple quotes for your parts in seconds