SLS - Selective Laser Sintering

SLS 3D Printing: Advanced designs and high-performance materials

What Is SLS 3D Printing and How Does It Work?

Selective Laser Sintering, or SLS, began as an attempt to solve a design problem: How do you create a prototype without having to wait the many months of lead time involved in the traditional manufacturing process? How do you make a copy straight off a CAD (computer automated design) file?

The person asking those questions was Carl Deckard, a mechanical engineering student at the University of Texas at Austin in the 1980s, who eventually patented the technology. Deckard developed the system with the help of his professor, Joe Beaman, and with the aid of a $30,000 grant from the National Science Foundation.

Originally intended to solve the problem of instant prototyping, SLS has continued to be essential for that purpose but has also become a low-volume production alternative to traditional manufacturing methods like injection molding.

How SLS works: General principles

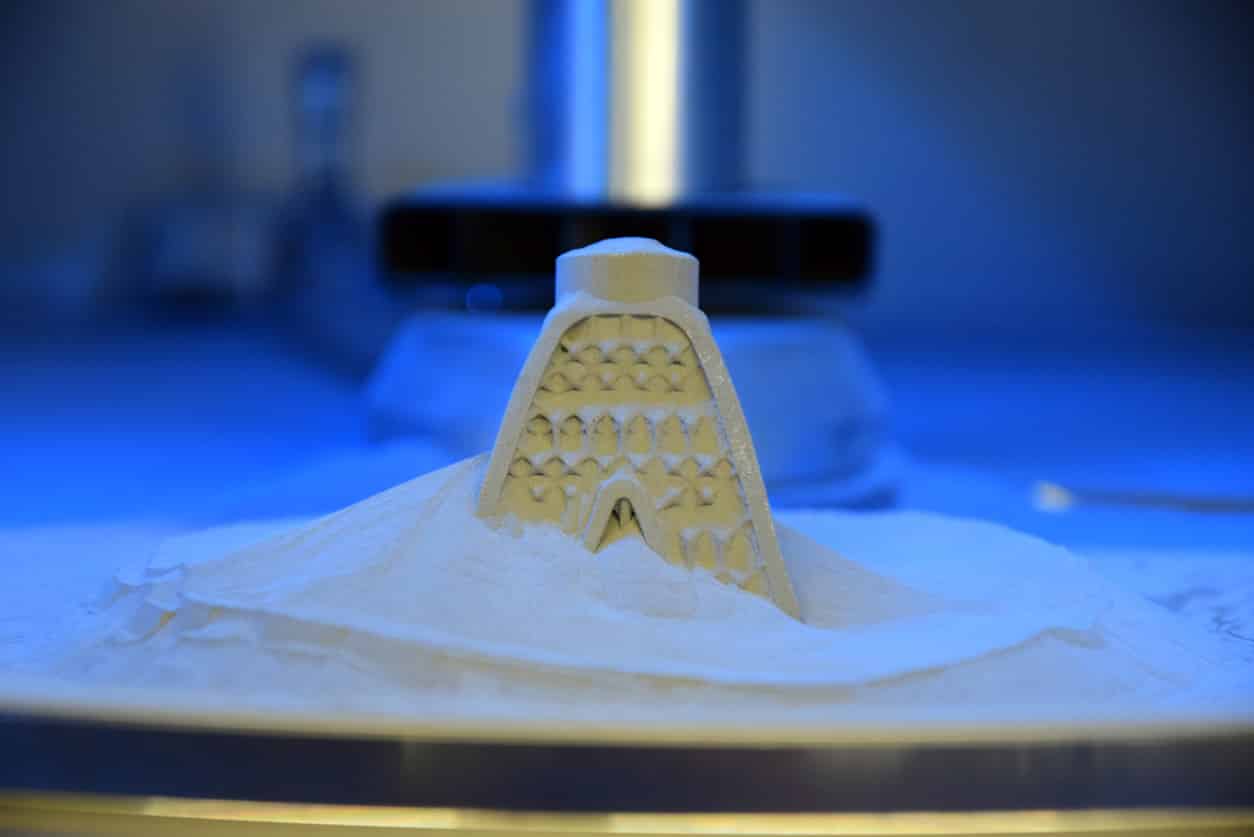

SLS is a type of powder bed fusion (PBF) 3D printing technology. In SLS, a high-power laser draws each layer into a bed of powder, usually Nylon. The laser sinters the powder particles together to form solid structures. Once a layer is complete, the build plate lowers slightly, and a powder recoater spreads new powder onto the previous layer. This technology is highly precise, with layer thicknesses typically ranging between 50 and 200 microns.

Once the prints are complete, the machine operator must remove and de-powder them. It is possible to recycle most of the unused powder by mixing it into fresh powder; another advantage of SLS. However, it is more efficient to print as many parts as will fit in the chamber at once.

General Characteristics

SLS is one of the most efficient forms of 3D printing available. It is destined for professional and industrial usage, the most affordable solutions starting at around $6,000. Post-processing machines such as depowdering stations and powder sieves are necessary to cover the entire workflow. Its main applications continue to be rapid prototyping, though some companies also use the technology for small production runs.

SLS has some key characteristics which make it superior to fused deposition modeling (FDM) or stereolithography (SLA) for specific applications. First among these is the fact that parts are printed while encased in a build chamber full of powder. The powder acts as its own support material, eliminating the need for any support structures. This also means it is possible to print incredible geometries that would be impossible for FDM or SLA, including functional moving parts requiring no assembly.

Another key characteristic of SLS is that the resolution of finished parts is of very high quality, though surfaces have a slightly grainy texture similar to very fine sandpaper. This porosity translates into objects that are easy to dye in many colors.

Finished models are also isotropic, meaning they have strength in all directions (contrary to anisotropic prints from technologies like FDM). SLS parts have good mechanical properties on par with injection-molded elements. In some cases, SLS 3D printing can even be superior to injection molding, considering no time-consuming die is required. Furthermore, SLS prints don’t require draft angles or other design constraints imposed by injection molding. For small objects with low-volume production runs (e.g., 500 to 1000 units), SLS can be a viable alternative to traditional manufacturing.

In terms of downsides, while SLS is certainly faster than traditional manufacturing from start to finish, it is still quite slow compared to other additive manufacturing methods. The entire build chamber must be heated to just below the plastic’s melting point before printing, and then it must be permitted to cool down for several hours before it is possible to remove the prints. Print times themselves are generally long, and all the post-processing steps (depowdering, sandblasting, etc.) can add up to be quite time-consuming as well.

The printing process also has some complexity. Oversintering, when trapped heat is unable to escape properly, can occur on small details, damaging the prints. Printing thinner walls can mitigate this problem by dissipating heat faster. It is important to note that parts are printed hollow and require escape holes of at least 5 mm in size to release powder.

Lastly, the biggest drawback to SLS 3D printing is almost certainly cost. Machines are expensive, with most industrial-grade systems running around $200K. Prices are coming down, however, and the lowest SLS 3D printer prices start at about $6K.

Which materials can SLS 3D printers use?

SLS 3D printers mainly use thermoplastic polymers in powder form, of which the most common and versatile material family is PA (polyamide), a.k.a. nylon. The standard PA-based powder can accommodate additives like aluminum, carbon fiber, and glass fiber.

Other SLS-compatible powders include TPE (thermoplastic elastomer) and TPU (thermoplastic polyurethane), rubber-like plastics, and PP (polypropylene), a chemical-resistant material.

Main applications of SLS 3D printing

SLS 3D printing is useful to a number of industries. Automotive and aerospace companies employ it extensively for prototyping and the production of brackets and enclosures. Some specific use cases are as follows.

The Ford Motor Company adopted 3D printing, including SLS, at the technology’s inception in the 1980s. Since then, Ford estimates that its in-house 3D printing lab has made a half-million parts used in prototype testing and has saved billions of dollars. To print metal parts, Ford employs a sister technology called SLM – selective laser melting – which is similar to SLS but creates metal parts through a melting process at higher temperatures.

In an example of ready-to-use manufacturing, Porsche Classic is using SLS to manufacture spare plastic parts for some of its rare classic cars. The company finds that 3D printing these parts on demand is the only practical method of supplying parts for vehicles that have been discontinued from factory production.

Node-Audio leveraged SLS 3D printing’s complex geometry capabilities to build a single-piece high-fidelity audio speaker cabinet. The innovative 3D-printed cabinet features an internal helical structure within which sound spirals for 1.6 meters, aiming to recreate a live music listening experience.

The Future of SLS 3D Printing

As with many other 3D printing technologies, the biggest areas for improvement lie in material diversity and hardware costs. The issue of cost is even more critical with SLS, but manufacturers have made huge advancements in recent years. It wasn’t long ago that all SLS machines cost upwards of six figures, and now several companies offer options below $20,000. It is quite conceivable that prices will become more accessible for small businesses in the coming years.

Meanwhile, designers interested in using selective laser sintering for their 3D modeling can explore print-on-demand services.

Get multiple quotes for your parts in seconds