Video SLS 3D Printing

Discover in video how the 3D Printing process SLS, also known as Powder bed fusion SLS works with 3DEXPERIENCE Make, the on-demand manufacturing, by Dassault Systèmes and his partner 3DProd.

Video: What is SLS 3D Printing?

Hello, today we’re here at 3D PROD to discuss SLS.

The SLS process is a 3D printing process. It involves sintering fine particles of polymer powder with the help of a laser to fuse them layer by layer.

How does SLS work?

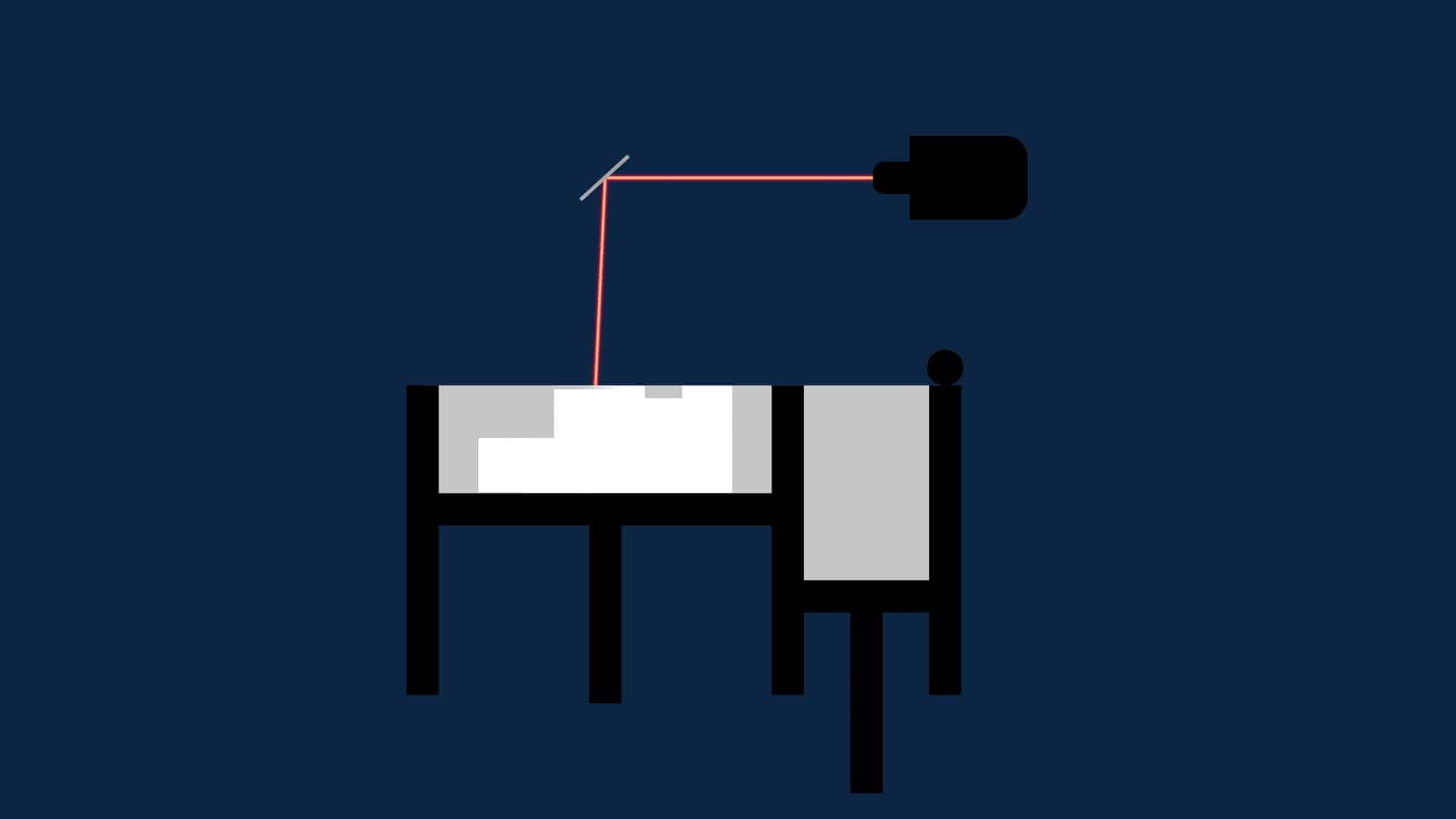

Basically, we’ve got a plate onto which a roller spreads a layer of powder. This layer of powder is sintered using a laser which reflects in a mirror based on the 3D model input to the machine. Once a layer is made, the roller applies a second layer, which is then sintered. This process continues until you have the finished object inside your powder cake. When the process is finished, a powder cake contains all the parts. We remove this powder cake from the machine and let it cool before moving it to the powder extractor and extracting the parts separately for cleaning.

What are the advantages and limitations of 3D Printing SLS?

The SLS process provides multiple benefits.

- First, it’s fast.

- Second is the quality of the parts, especially the ones with complex shapes.

- Third is the range of compatible materials.

3D Printing SLS has three main drawbacks.

- The first is space. The SLS process requires large, dedicated spaces.

- The second is the quantity of materials used. A lot of powder remains inside the powder cake that is not sintered and is no longer usable. This can increase the cost per part printed.

- The third is the cost of the technology which remains high for certain parts, especially the laser.

What are the usages in the industry of SLS?

In terms of use, many sectors use the SLS process because it works with a range of materials and it can handle complex shapes when prototyping. 3D Printing SLS is actively used in various industries such as the aerospace, automotive, consumer products and architecture sectors for making detailed prototypes.

In terms of functional parts, the SLS process is used in robotics and for drones. It’s also used in the medical industry to make implants and prosthetics which are tailored to patients.

Get multiple quotes for your parts in seconds