Video Rapid prototyping

Discover in video what is prototyping with 3DEXPERIENCE Make, the on-demand manufacturing platform from Dassault Systèmes, and its partner Ligerium.

Video What is rapid prototyping?

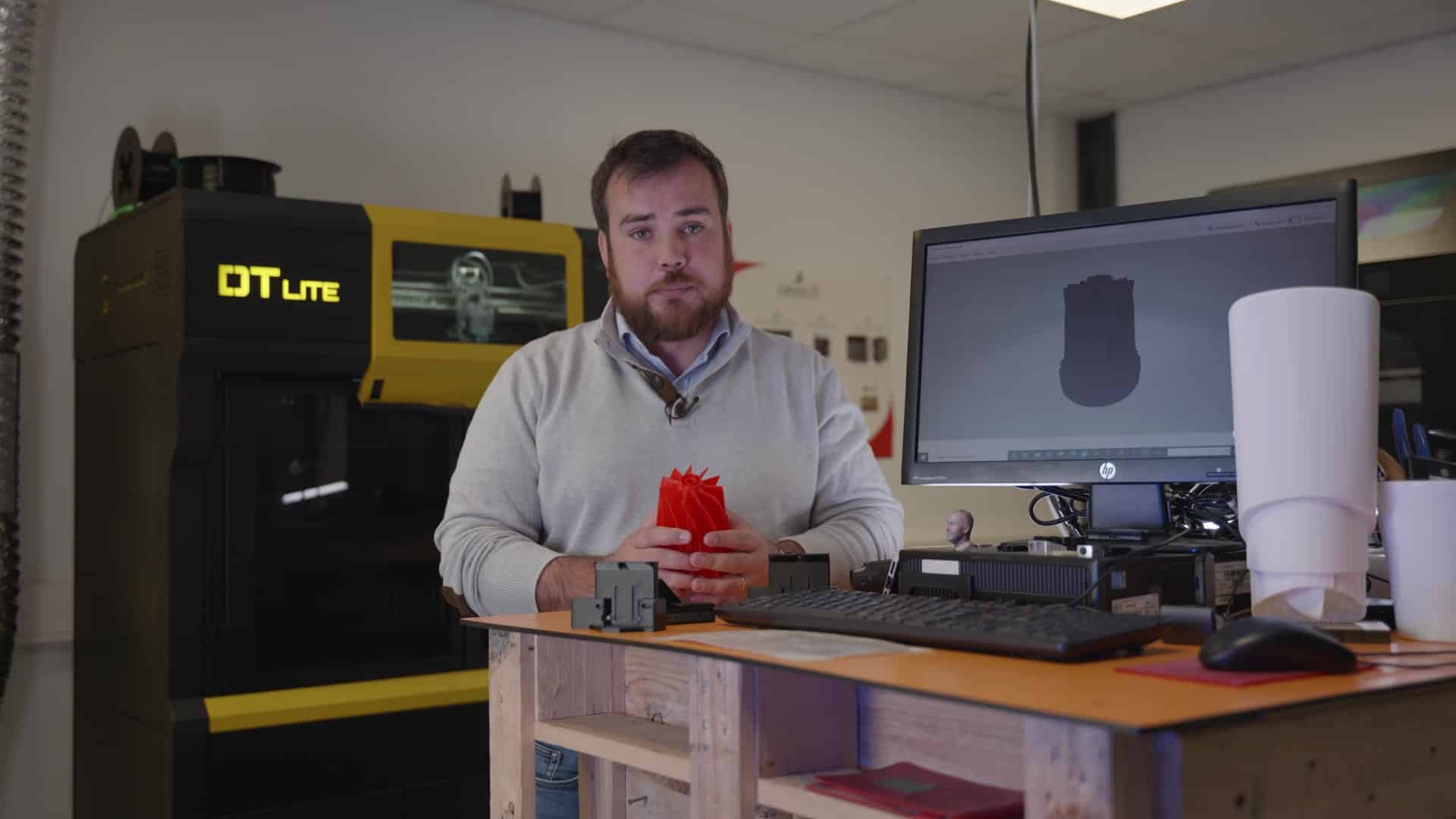

Hello, today we’re live from Ligérium 3D to discuss prototyping, and more specifically, rapid prototyping. Prototyping is the creation of a sample; it’s a sketch of a project, transitioning from idea to reality. Practiced for centuries, it enables the development of a product for testing before potential mass production and marketing. As such, prototyping is regularly used for shape validation, visual validation, functionality validation, mechanical tests, assembly tests or process and material tests.

What is the difference between prototyping and rapid prototyping?

Today, rapid prototyping is much talked about. This concept is made possible by the arrival of new manufacturing technologies and CAD, Computer-Aided Design.

It enables manufacturing in a few hours with high-precision products requiring minimal human intervention.

Rapid prototyping has three main benefits:

- faster prototyping to accelerate research and development,

- prototyping through more cost-effective technologies for one-off manufacturing,

- prototyping complex shapes that cannot be made or are too expensive using traditional processes.

What are the appropriate manufacturing processes for rapid prototyping?

Rapid prototyping relies heavily on additive manufacturing technologies that check most of the boxes for the benefits just mentioned. And as with any manufacturing project, to select the right technology, we must ask ourselves what we want to validate.

There are three main technologies:

- fused deposition modeling,

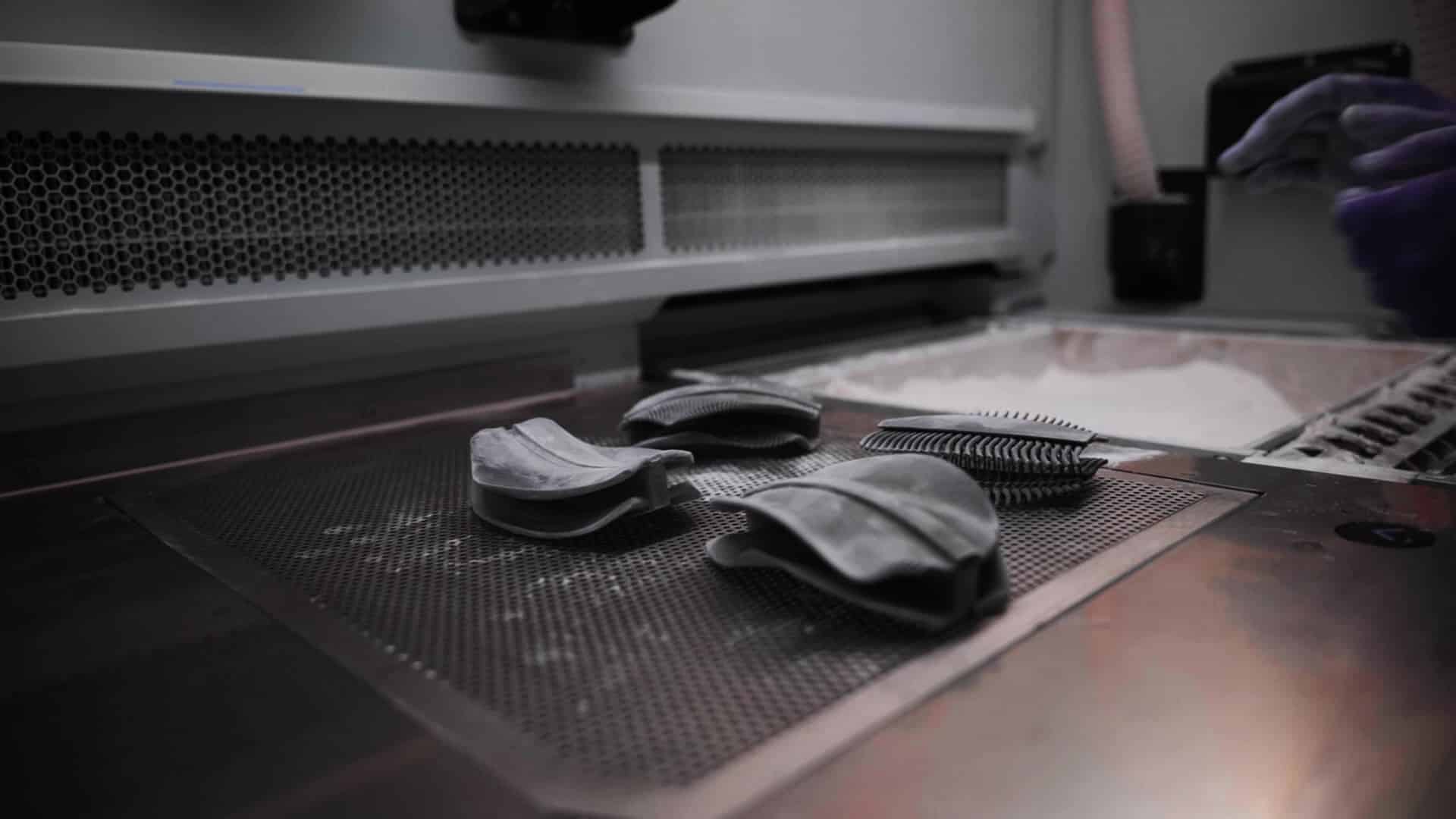

- powder sintering

- and stereolithography.

More specifically, fused deposition, which gives a slightly less qualitative surface finish, is mainly used for shape validation and resistance tests.

The rapid prototyping platform phenomenon

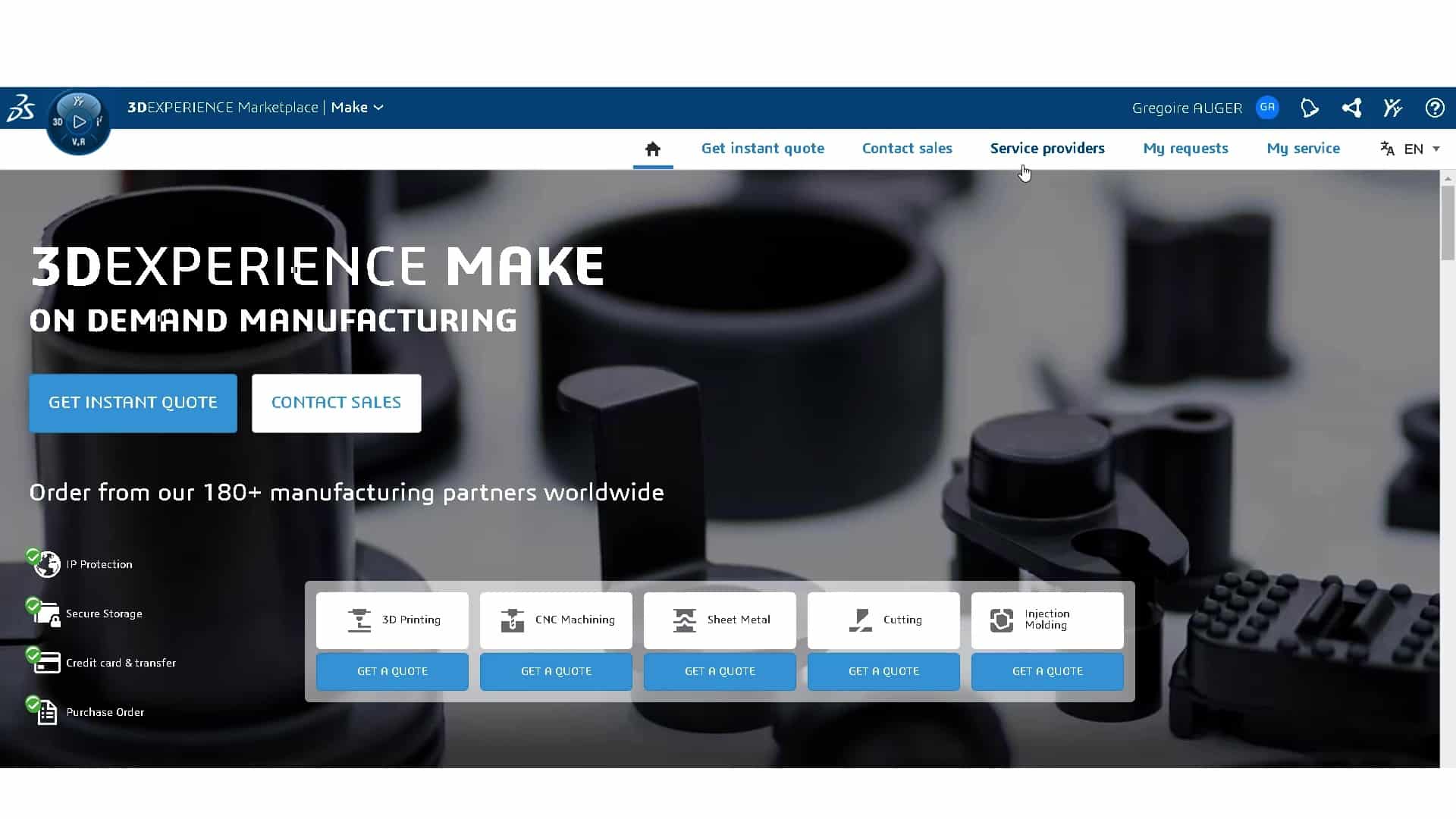

Photopolymerization, which is a fast process ensuring high precision, can be used for shape and visual validation. Powder sintering, which produces solid parts, is mainly used for complex prototypes and mechanical resistance tests. Rapid prototyping is also promoted through the generalization of the concept of on-demand manufacturing and the emergence of platforms such as the Make service of Dassault Systèmes’

3DEXPERIENCE Marketplace. This service helps you find local subcontractors who can quickly adapt to any type of project.

Get multiple quotes for your parts in seconds