Video 3D Printing Material Jetting

Find out in video how the Material jetting MJ 3D printing process works with 3DEXPERIENCE Make, the on-demand manufacturing platform, from Dassault Systèmes and its partner Any Shape.

Video: What is material jetting?

Hello. Today we’re at Any Shape to discuss Material Jetting. Material Jetting is an additive manufacturing process, also known as MJ 3D printing. It’s a process enabling the manufacturing of layered parts by solidifying hundreds of photopolymer microdroplets using a UV light source.

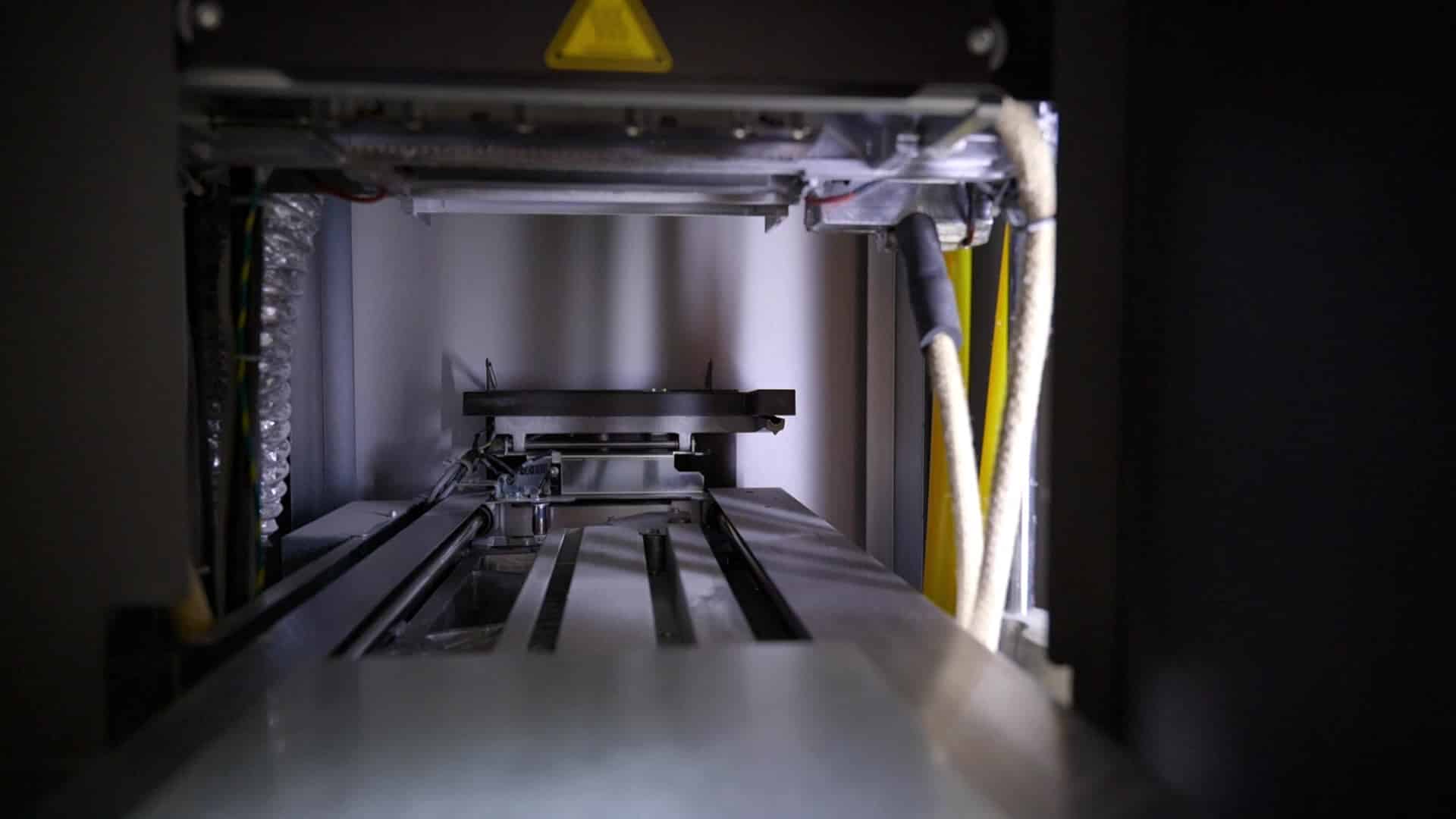

How does material jetting work?

So, how does it work in practice? First, you need a liquid photopolymer resin heated between 40 and 70° to produce a viscosity to fit the print head. This liquid resin is then be projected as hundreds of micro-droplets through the print head and solidified by an ultraviolet lamp in the same print head. This will help you to create a layered final product. At the time of Material Jetting printing, you must automatically use support structures. These support structures can be printed in various soluble materials such as water and wax when melting. This requires a post-treatment phase after printing to remove them.

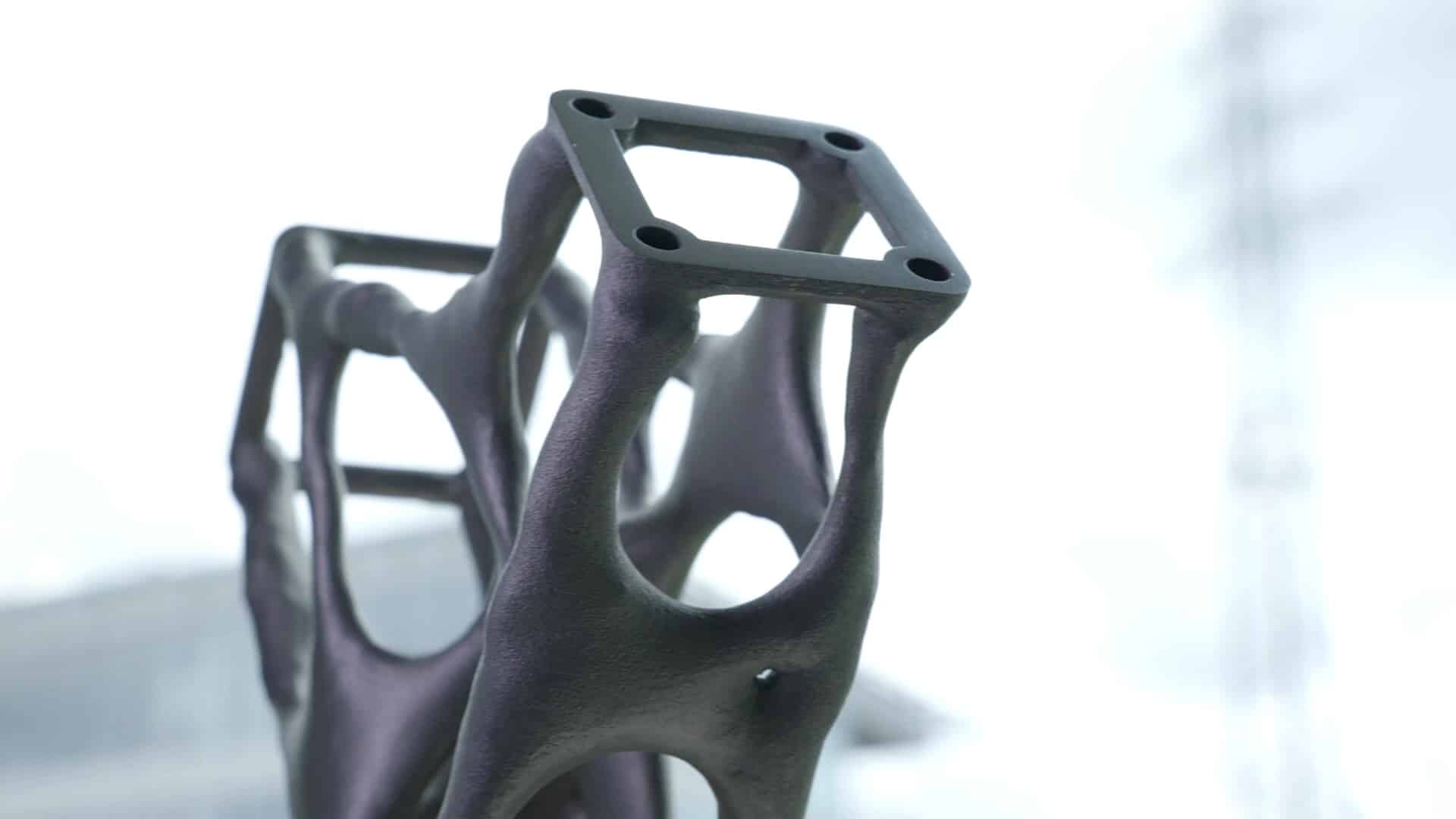

What are the advantages and disadvantages of material jetting?

Material Jetting is one of the most precise additive manufacturing processes which deploys photopolymerization. It’s one the few processes that enables multimaterial and full color printing. It produces a near-perfect surface finish, closely resembling plastic injection, providing high dimensional accuracy. As for drawbacks, Material Jetting is a costly process, which can be a barrier to entry for many applications. Materials are also sensitive to light and UV over time, as with photopolymerization.

What are the applications of material jetting?

Given its excellent surface finish, Material Jetting is widely used for visual validation and proof of concept, particularly in the cosmetics and consumer goods industries.

Get multiple quotes for your parts in seconds