Video 3D Printing Carbon DLS

Discover in video how the 3D Printing process Digital Light Synthesis (DLS) works with 3DEXPERIENCE Make, the on-demand manufacturing, by Dassault Systèmes and his partner ERPRO.

Video: What is 3D Printing DLS by Carbon?

Hello, today we’re live from ERPRO Group to discuss Carbon's DLS manufacturing process.

DLS technology, which stands for “Digital Light Synthesis,” is an additive manufacturing process resembling Stereolithography (SLA) developed by the Carbon brand. We also talk about “clips” which translates into continuous liquid interface production.

How does Digital Light Synthesiswork?

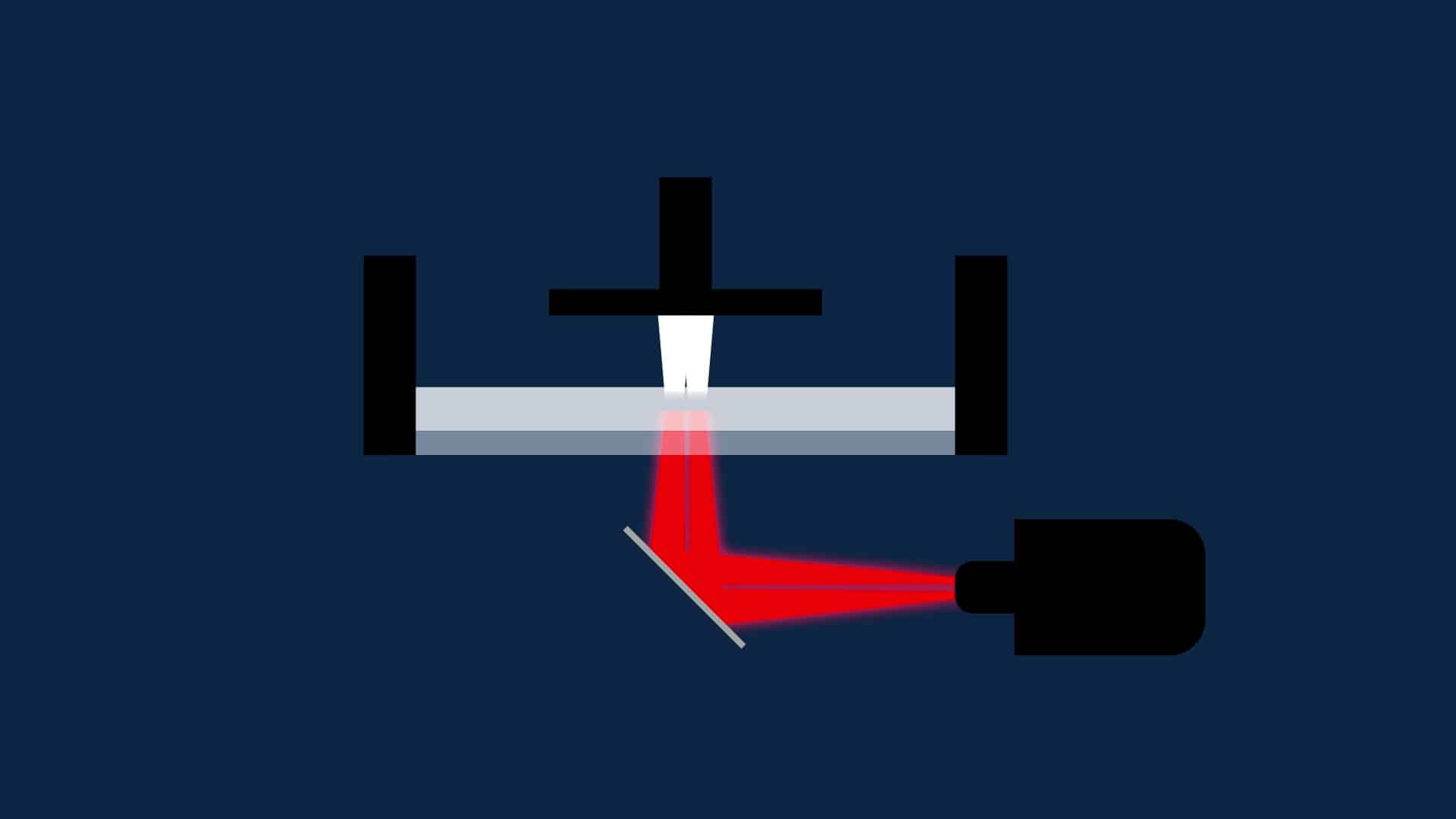

Like their SLA counterparts, 3D DLS printers use a liquid photosensitive resin vat with a transparent bottom. The manufacturing platform is then lowered to deploy layered manufacturing of a part. The light source is what differs between these two processes. 3D DLS printers will use a digital screen projector located under the resin tank. Using a matrix of micromirrors, this projects a successive sequence of layers onto the entire manufacturing platform through an oxygen-permeable window to ensure continuous resin polymerization. As the manufacturing process advances, the platform in contact with the resin rises to reveal the finished part. Upon completion, the recovered part must be washed in this machine type before solidifying in an oven.

What are the Advantages and limitations of Digital Light Synthesis?

DLS technology offers multiple benefits through making complex parts and its proven mechanical properties, not to mention speed of execution, pinpoint accuracy, and zero waste. DLS also lets you print flexible materials. It has two main drawbacks. First off, DLS is pricey, especially for iterations and corrections during prototyping. Second is the limited number of materials which are only produced by Carbon and are unique.

What are the applications of Digital Light Synthesis?

In terms of application, it’s best to talk in examples. DLS technology is world-renowned as a shoe sole manufacturer for Adidas at ERPRO Group. On top of that, DLS is deployed as part of several different industrialized production projects. Two notable examples include the manufacture of custom earphone tips and mass production of perfume bottles.

Get multiple quotes for your parts in seconds