Water Cutting

Discover what is the manufacturing cutting process Water Cutting and its usage in the industry.

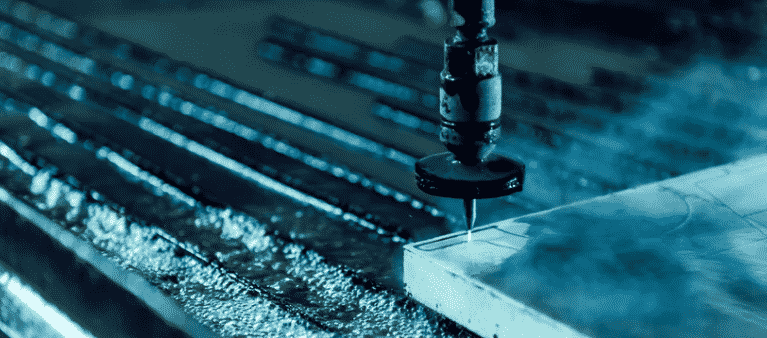

Introduction to Water Cutting

Water cutting is an industrial cutting process that occurs when a very high-pressure jet of water, or a mixture of water and an abrasive substance, cuts a broad range of materials. The tool used in water cutting is called a water jet cutter, also known as a water jet, and sometimes spelled “waterjet.” An abrasive substance is necessary to cut tough materials like metal or granite, in these cases it is called an abrasive jet. Softer materials such as rubber or wood do not require an abrasive substance and can benefit from a pure waterjet.

The water jet cutter carefully controls the erosion of the various materials using a jet of water at a high velocity and pressure. It is a frequently used method in the fabrication of machine parts and is particularly beneficial when the material being cut is sensitive to the high temperatures generated by other methods. Mining and aerospace, among others, are industries that use water jet cutting for cutting, shaping, and reaming.

Theoretically, the first application of water cutting occurred in the mid-19th century with the use of high-pressure water for erosion purposes in hydraulic mining. But it was really in the 1930s when the process became adopted for industrial cutting processes in the paper industry. Abrasive water jets also emerged in the 1930s. The post-war era continued to made advancements, at first with softer materials, eventually leading to the first ultra-high-pressure liquid to cut hard materials. The 1960s and ’70s led to the development of a pulsing water jet and as the development of high-pressure systems advanced, the merging of the two technologies has ushered in its modern application.

Get multiple quotes for your parts in seconds