Turning

Discover what is the manufacturing process CNC Machining Turning and its usage in the industry.

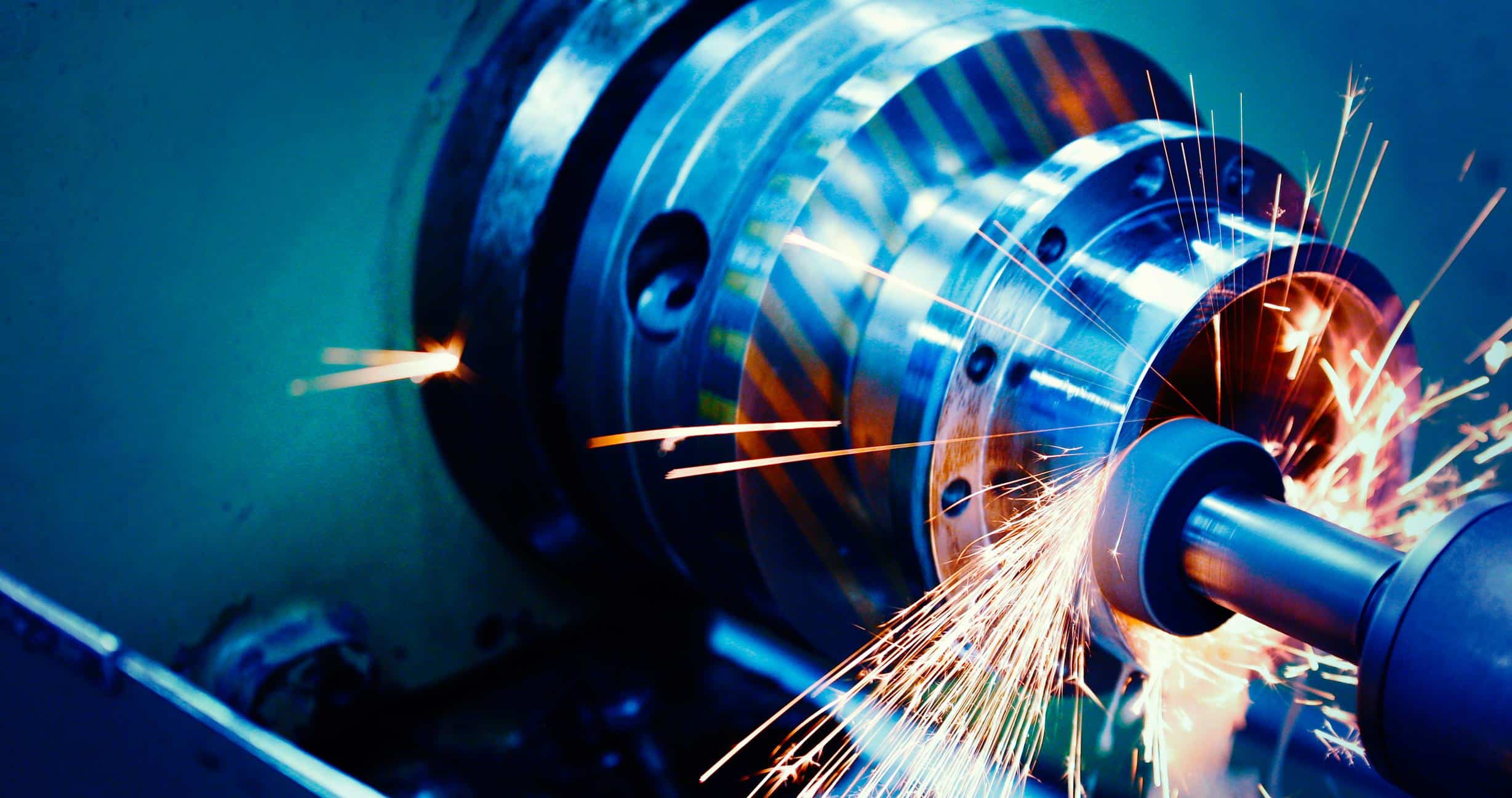

Introduction to Turning

Turning is a Substractive machining process that uses a cutting tool, typically a lathe, to achieve a variety of shapes for end-use plastic, metal, wood, or stone parts. Briefly, the use of a rotating metal rod performs turning. At the same time, a cutting tool is held against a rigid piece of material, generally cylindrically shaped, to remove material and create final parts. Today, CNC (Computer Numerical Control) is the most common automated form of turning.

Turning takes a fairly rigid material such as metal, plastic, stone, or wood and rotates it while carving it with a cutting tool that uses one, two, or three axes of motion, resulting in diameter and depths of remarkable precision. It is possible to perform turning on either the interior or exterior of a cylinder (also known as boring) to create cylindrical parts of different forms.

Four turning operations

There are four specific turning operations:

- Turning is one of the most basic machining processes, which involves a rotating part cut by a single-point cutting tool whose movement is parallel to the axis of rotation. Turning can be performed on both the external and internal surfaces of parts.

- Facing is frequently the first operation and often the last, performed in the production of machined parts. It moves the cutting tool at right angles to the axis of rotation while the part rotates.

- Parting creates deep grooves that remove an entire or partial segment from its parent part.

- Grooving is the cutting of grooves at a specific depth and can be performed on internal and external surfaces, as well as on the face of a part. It encompasses face grooving, boring, drilling, knurling, reaming, threading, and polygonal turning.

Get multiple quotes for your parts in seconds