Laser Cutting

Discover what is the manufacturing cutting process Laser Cutting and its usage in the industry.

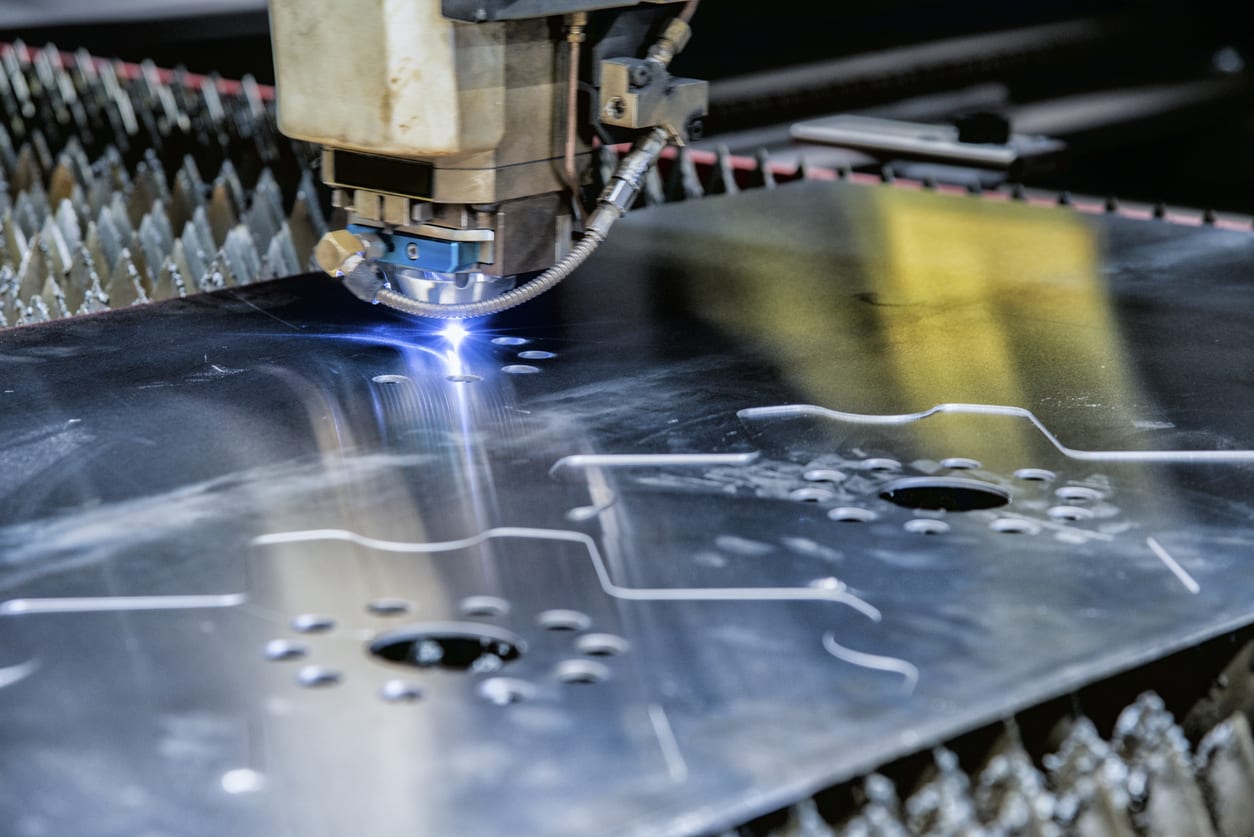

Introduction to Laser Cutting

As its name implies, laser cutting is a digital subtractive technique that uses laser technology to cut or engrave a variety of materials. Although it is most broadly adopted in the industrial manufacturing sector, it is gaining traction with small establishments like schools and small businesses and among hobbyists. It is a highly precise method and can be applied to numerous different materials such as acrylic, plywood, MDF (Medium-Density Fiberboard), cardboard, POM (PolyOxyMethylene), aluminum, steel, stainless steel, among others.

Despite it being an expensive cutting technology, laser cutting offers a precision that’s hard to match. The three types of lasers are: CO2 (gas), fiber, and Nd:YAG/Nd:YVO (crystal lasers). CO2 lasers are mainly suitable for non-metallic and most plastic materials. Fiber lasers are mostly suitable for metal marking by annealing for metal engraving, and for high-contrast plastic markings. Like fiber lasers, crystal lasers belong to the solid-state laser group and are suitable for metals, coated metals, plastics, and some ceramics.

The American electrical engineering and manufacturing company Western Electric Engineering Research Center was the first to design a laser-cutting machine to drill holes in diamond dies in 1965. Shortly after, the British developed laser-assisted oxygen jet cutting for metals in 1967. The 1970s ushered in an era of laser titanium cutting specifically for aerospace applications. During this period, scientists adapted CO2 lasers to cut nonmetals because they weren’t powerful enough to surmount the thermal conductivity of metals.

Laser cutting involves the output of a high-power laser directed, most commonly, through optics. In tandem with CNC (Computer Numerical Control), the optics direct the laser beam at the material by focusing it to melt, burn, vaporize, or blow away (by a jet of gas) a pattern defined by a CNC interface. The end product delivers a high-quality surface finish for edges. Industrial laser cutters are used to cut flat sheet, structural, and piping materials.

Get multiple quotes for your parts in seconds