Metal

Discover what is Metal, a manufacturing material, and its usage in the industry.

Introduction to Metal

Humans have fabricated goods from metal over the millennia. Depending on the metal, historians discovered some objects as far back as thousands of years BC.

Metals are generally hard, opaque, and shiny materials that exhibit good electrical and thermal conductivity. Although approximately 91 of the 118 elements of the periodic table are metals, they can be elements, compounds, or alloys. They are generally malleable so that they can be shaped by hammering or pressing without breaking or cracking. Metals are also fusible, meaning they can be fused or melted and exhibit a ductility that makes it possible to stretch them out into a thin wire. Consequently, metals are an essential part of our lives in high-rise buildings, bridge construction, automobiles, home appliances, jewelry, tools, pipes, railways, and many other places.

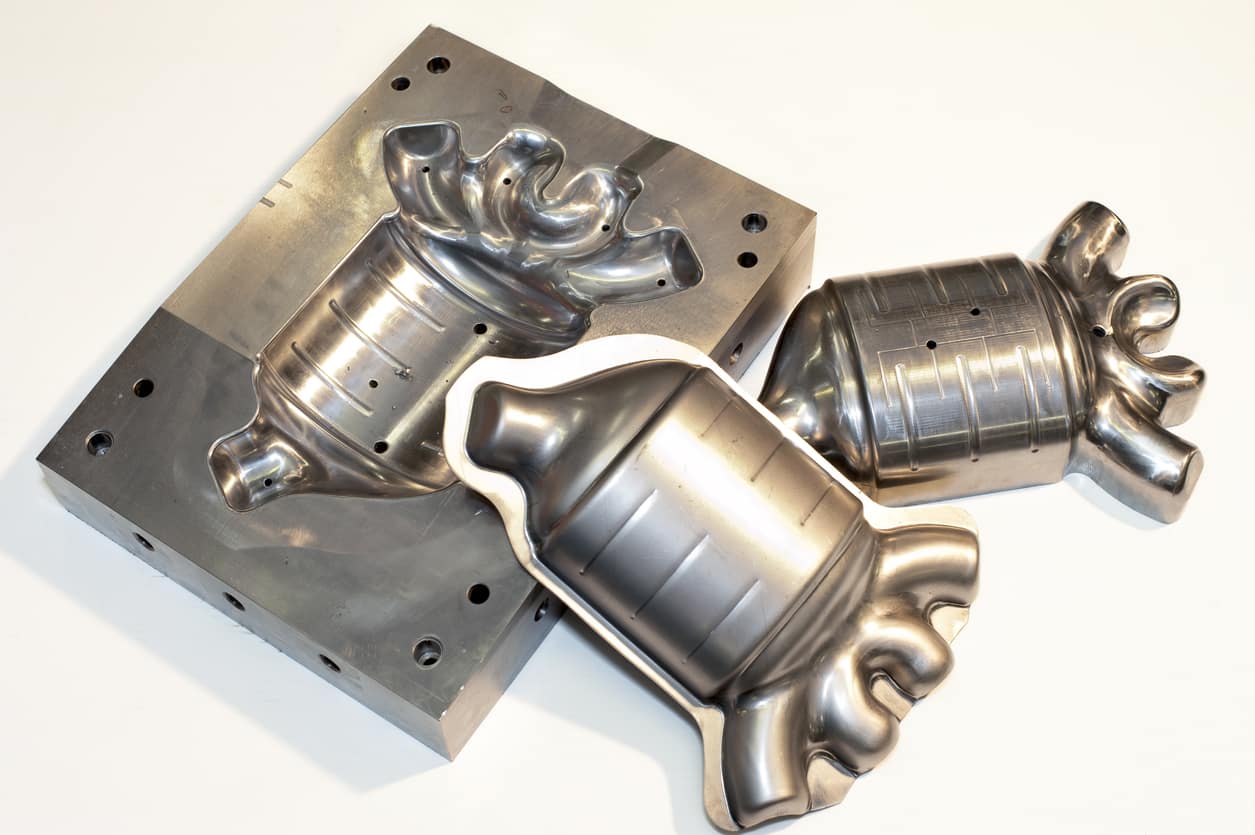

Metallurgy is the driving force for the technical advancement of metalworking. It aims to apply the science behind the metal to the most appropriate application, for instance, in consumer and manufactured products, transportation, railway, aeronautics, marine, and many other fields. As 3D Printing technology has advanced, so have the choices of applicable metals. Many different processes are used to shape metal including, casting, forging, rolling, laser cladding, extrusion, sintering, machining, fabrication, and 3D printing—metals for standard manufacturing processes.

Discover SOLIDWORKS 3DEXPERIENCE for Makers

Generic Metal Materials

Aluminum metal

Aluminum is a silvery-white, soft, non-magnetic, ductile metal in the boron group of chemical elements. The most remarkable properties of aluminum are its low density and resistance to corrosion through the phenomenon of passivation. It is the second most commonly produced metal after iron, with a global production of 31.9 million tons. Aluminum and its alloys are critical to the aerospace industry and widespread in the transportation and building industries. Additionally, packaging, food and beverage containers, household items, street lighting poles, ship masts, electrical transmission lines, and many other applications, use aluminum.

Cobalt metal

Cobalt is a chemical element found in the Earth’s crust only in a chemically combined form, except for small deposits found in alloys of natural meteoric iron. The free element is a hard, lustrous, silver-gray metal. Since ancient times, jewelry and paints creators have used Cobalt-based blue pigments to render a distinctive blue tint to the glass. The main application of cobalt is the production of high-performance alloys employed for their magnetic, wear-resistant, and high-strength properties. Additionally, manufacturers of batteries, catalysts, pigments, coloring, and radioisotopes utilize cobalt.

Cast Iron metal

Cast iron is a group of iron-carbon alloys with a carbon content greater than 2%, particularly beneficial for its relatively low melting temperature. Although cast iron tends to be brittle, its relatively low melting point, good fluidity, castability, excellent machinability, and deformation and wear resistance have made it an engineering material used in a broad spectrum of applications, including pipes, structural, and machine, and automotive industry parts. It is also resistant to destruction and weakening by oxidation. Carbon, silicon, manganese, chromium, molybdenum, titanium, vanadium, nickel, and copper are among the numerous alloying elements.

Cast steel metal

Cast steel defined as steel made by melting wrought iron in crucibles with charcoal. It is similar to cast iron, with the main difference in carbon content. Cast steel typically contains between 0.1–0.5% carbon compared to cast iron, typically with more than 2% carbon. Cast steel exhibits greater shrinkage than cast iron and is more difficult to pour. Its shrinkage makes it more susceptible to stresses, which requires a comprehensive inspection process throughout the casting process and makes it more resource-intensive.

Ferrous alloys metal

Ferrous alloys, also known as ferroalloys, are iron-based alloys with a high proportion of one or more other elements such as manganese, aluminum, or silicon. The production of steels and alloys uses it. The iron and steel industry’s leading consumer of ferrous alloys employs them for their distinctive qualities and essential functions during production.

Gold metal

Gold is a precious metal that is a bright, slightly reddish-yellow, dense, soft, malleable, and ductile metal in its purest form. Its main industrial use is an electrical connector in computers and electrical devices thanks to its high malleability, ductility, resistance to corrosion and most other chemical reactions, and electrical conductivity. Infrared shielding, colored-glass production, gold leafing, and tooth restoration also uses gold. Additionally, jewelry utilizes often it. Certain gold salts and radioisotopes are still used as anti-inflammatories in medicine and as alloys in restorative dentistry.

H Steel metal

H Steel is a European steel-grade, specifically optimized for “High Tensile Strength Flat products.”

Low melting alloys metal

Low melting alloys, also called fusible alloys, are easily meltable at relatively low temperatures. Low melting alloys are most commonly used as coolants because of their stability under heat. They can give much higher thermal conductivity than most other coolants, particularly with alloys made with a high thermal conductivity metal such as indium or sodium. They are also used for cooling nuclear reactors and in automatic fire sprinklers.

Molybdenum metal

Molybdenum is a chemical element that is gray metallic gray in appearance. It exists not as a free metal but in various states of oxidation in minerals and has the sixth-highest melting point of any element. Because it rapidly forms hard, stable carbides in alloys, 80% of the world’s molybdenum production is used in steel alloys, including high-strength alloys and superalloys. Its application is most prevalent in structural steel, stainless steel, chemicals, tools, high-speed steels, cast iron, molybdenum elemental metal, and superalloys. In its pure elemental state, molybdenum is also used as a fertilizer, as a pollution analyzer in power plants, and in mammography and medical imaging.

Nickel metal

Nickel is a silvery-white lustrous metal with a slight golden tinge and is hard and ductile. Predominantly an alloy metal, the main use of nickel is in nickel steels and nickel cast irons for its tensile strength and toughness properties as well as its elastic limit. Manufacturers also use it as an alloy in nickel brasses and bronzes and alloy it with copper, chromium, aluminum, lead, cobalt, silver, and gold. Popular Nickel alloys include Inconel, Incoloy, Monel, and Nimonic. Commonly used in coins both historically and in modern times, nickel is also used as a stainless steel alloy in everyday consumer and industrial products such as alnico magnets, rechargeable batteries, electric guitar strings, microphone capsules, plating on plumbing fixtures, and special alloys such as permalloy, elinvar, and invar. It is also used for plating and as a green tint in glass.

Niobium metal

Niobium, formerly known as columbium, is a soft, grey, ductile transition metal often found in pyrochlore and columbite. Brazil is the leading producer of niobium and ferroniobium, an alloy of niobium and iron with a niobium content of 60–70%. Niobium is used mainly in alloys, mainly in special steel as used in gas pipelines. Although these alloys contain a maximum of 0.1% niobium, the small percentage enhances the strength of the steel. It is also an essential superalloy for jet and rocket engines because of its temperature stability. Additionally, various superconducting alloys containing titanium and tin have niobium, for example, in the superconducting magnets of MRI (Magnetic Resonance Imaging) scanners. Other applications of niobium include welding, nuclear industries, electronics, optics, numismatics, and jewelry.

Non-ferrous alloys metal

Non-ferrous alloys are alloys that do not contain iron in appreciable amounts. Although they are more expensive than ferrous (iron) alloys, well known for their lightweight, higher conductivity, non-magnetic property, or corrosion resistance. The most important non-ferrous metals include aluminum, copper, lead, nickel, tin, titanium, zinc, and brass alloys. Precious metals such as gold, silver, and platinum and exotic or rare metals such as cobalt, mercury, tungsten, beryllium, bismuth, cerium, cadmium, niobium, indium, gallium, germanium, lithium, selenium, tantalum, tellurium, vanadium, and zirconium are also non-ferrous.

Platinum metal

Platinum is a dense, malleable, ductile, highly unreactive, precious, silverish-white transition metal. Its scarcity and use in essential applications make it an expensive precious metal commodity. Platinum is one of the least reactive metals and has remarkable corrosion resistance, even at high temperatures; therefore, it is a noble metal. Platinum applications include catalytic converters, laboratory equipment, electrical contacts and electrodes, platinum resistance thermometers, dentistry equipment, and jewelry.

Silver metal

Silver is a soft, white, lustrous transition metal that exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. Although it is more abundant than gold, it has a longstanding classification as a precious metal. Historically used in coinage, today, silver is commonly used to produce bullion coins. Solar panels, water filtration, jewelry, ornaments, tableware are examples of silver applications. The industrial sector utilizes silver to make electrical contacts and conductors, specialized mirrors, window coatings, and for catalysis of chemical reactions. Photography, X-rays, disinfectants, catheters, and other medical instruments contain silver compounds.

Stainless steel metal

Stainless steel, also known as inox steel, is a steel alloy with at least 10.5% chromium content by mass. The most remarkable property of stainless steel is its corrosion resistance. The alloy is milled into coils, sheets, plates, bars, wire, and tubing before it goes on to be applied in the production of food-handling equipment, cookware, cutlery, surgical instruments, industrial equipment, major appliances, architecture, firearms, 3D printing, and many other products.

Steel metal

Steel is an alloy of iron and carbon, and other elements. Thanks to its high tensile strength and low cost, it is a major component used in buildings, infrastructure, tools, ships, automobiles, machines, appliances, and weapons. There are several categories of steel, including long steel, flat carbon steel, weathering steel (COR-TEN), stainless steel, and low-background steel.

Tantalum metal

Tantalum, formerly known as tantalium, is a rare, hard, blue-gray, lustrous transition metal that is highly corrosion-resistant. Thanks to its chemical inertness, it is a valuable substance for laboratory equipment and a substitute for platinum. Today, tantalum capacitors in electronic equipment such as mobile phones, DVD players, video game consoles, and computers use it. Manufacturers also utilize it to produce alloys and superalloys for jet engine components, chemical process equipment, nuclear reactors, and missile parts.

Titanium metal

Titanium is a lustrous transition metal with a silver color, low density, and high strength. Its resistance to corrosion in seawater, aqua regia, and chlorine makes it one of the strongest but costly metals used in manufacturing metalwork. The vast majority of titanium ore is used for pigments, additives, and coatings after being refined into titanium dioxide. Additionally, the aerospace and marine industries utilize titanium alloys because of their solid and resistant properties, making them suitable for aircraft, armor plating, naval ships, spacecraft, and missiles. Due to its superior corrosion resistance, industrial applications of titanium include welded piping and process equipment (heat exchangers, tanks, process vessels, valves) in the chemical and petrochemical industries. The pulp and paper industry also utilize titanium, ultrasonic welding, wave soldering, and sputtering targets.

Additionally, titanium is particularly favorable in automotive and motorcycle racing applications for its lightweight and high strength and rigidity are essential. Consumer items produced with titanium include sporting goods, eyewear, and jewelry. Specialized implementation of titanium includes the medical and nuclear waste storage industries.

Tool steel metal

Tool steel refers to various carbon and alloy steels that are particularly well suited for making tools. Their suitability is based on their exceptional hardness, resistance to abrasion and deformation, as well as their ability to hold a cutting edge at elevated temperatures. Consequently, tool steels are suited for shaping other materials, for example, for cutting, pressing, extruding, and coining metals and other materials. They are also commonly used in the production of injection molds for their resistance to abrasion, which is an important criterion for a mold that will be essential to produce hundreds of thousands of moldings of a product or part.

Tungsten metal

Tungsten is a free element, and rare metal found naturally on Earth, almost exclusively in chemical compounds. The robustness of tungsten is truly remarkable; it has the highest melting point of all elements, the second-highest boiling point, and is 19.3 times denser than water. Tungsten is mainly used to produce hard materials, most notably tungsten carbide, as well as in alloys and steel. Manufacturers of electronics, nanowires, and armaments use it. There are also applications such as weights, counterweights, ballasts in yachts and aircraft, Formula One and NASCA race cars.

Zinc metal

Zinc is a chemical element that exhibits only one normal oxidation state and features a bluish-white, lustrous color. It is classified as a diamagnetic metal and is hard and brittle at most temperatures but becomes malleable between 100 and 150 °C. Zinc is also a fair conductor of electricity. One of its major applications is iron plating (hot-dip galvanizing) because of its corrosion resistance. Electrical batteries, small non-structural castings, and alloys such as brass use it also. Zinc is a standard alloy of brass. Industrial sector produces it as a compound. Likewise, it is an essential mineral for health in humans, animals, plants, and microorganisms.

Zirconium metal

Zirconium is a lustrous, grey-white, soft, ductile, and malleable transition metal that is solid at room temperature, though it is hard and brittle at lesser purity. It is highly resistant to corrosion by alkalis, acids, saltwater, and other agents. Mainly used as a refractory and opacifier, small amounts of zirconium are also used as an alloying agent for its strong corrosion resistance. High-temperature and biomedical applications could use zirconium as a compound. Nuclear, space, and aeronautics industries could utilize it as a metal. Medical imaging employs its isotopes.

Metal materials for 3D printing processes

Metals for the 3D Printing manufacturing process have restrictions compared to standard metals.

Aluminum can be 3D-printed with aluminum powder sintered together by a laser to produce end-use metal parts that are equally as good as machined models. It can be used for complete functional parts, spare parts, and jewelry. The two main 3D Printing techniques for aluminum are Direct Metal Laser Sintering (DMLS) and Select Laser Melting (SLM). In contrast to traditional shiny milled aluminum, 3D printed aluminum is a bit grayer and more matte with a slightly rougher and less defined surface. Aluminum models are robust, precise, and can have feature sizes as small as 0.25 mm.

Brass is an alloy of copper and zinc, frequently used in musical instruments because of its acoustic properties and ductility. There are many applications that seek an economical substitute for precious metals that utilize it. In 3D Printing, brass is typically used to produce detailed miniatures, sculptures, jewelry, or preprint tests (to form-fit before making with gold or silver). Brass is an economical alternative to gold. Wax 3D Printing and lost wax casting are techniques used to build brass designs. It can be coated with a natural, yellow gold-plated, red gold-plated finish or rhodium-plated, chrome-plated, or black color-plated polish.

Bronze is a copper-based alloy and is an affordable and robust material for printing metal. In 3D Printing, bronze is typically used to produce detailed miniatures, sculptures, jewelry, or preprint tests (to form-fit before making gold or silver). Wax 3D Printing and lost wax casting are techniques used to build bronze designs. It can be coated with a polished PU or natural PU coating or left natural and uncoated.

Copper is a soft, malleable, ductile metal with very high thermal and electrical conductivity. Known for its reddish color and greenish tarnishing, it is affordable for 3D Printing models. Typically, copper is used in 3D Printing to produce small decorative models like coins, medals, connectors, or statues. Wax 3D Printing and lost wax casting are techniques used to build copper designs. It is polished after 3D Printing but is also very susceptible to tarnishing.

Industrial Metal is suitable for prototypes and end-use parts with various metals and alloys. Industrial metals are laser-sintered from metal powder, including aluminum, stainless steel, bronze, and cobalt-chromium. It is also suitable for complex designs with intricate details, mechanical parts, and moving and assembled parts. The main drawback is that the cavities within a plan require using escape holes.

Gold is mostly a suitable material for printing jewelry in either 14k or 18k solid gold mixed with an alloy for durability. Manufacturers use wax 3D Printing and lost wax casting to produce gold models. 14K and 18K gold can be 3D printed in three golden colors: bright yellow, red, and white.

High-detail Stainless Steel delivers a significant level of detail and strength to 3D printed models, making it suitable for miniature figurines, jewelry, bolts, key chains, bolts, and much more. The 3D Printing technique used with high-detail stainless steel involves a precision inkjet printer that binds layers of ultra-fine grains of stainless steel powder together. 3D Printing services can finish it with matte, satin, or gloss finishing.

Sterling silver 3D printed models are composed of 92.5% pure silver and 7.5% of another metal, usually copper. Silver is very malleable and exhibits very high electrical and thermal conductivity. Sterling silver is a standard alloy in jewelry fabrication, which is where it’s typically applied to 3D Printing. Rings, earrings, and bracelets are the most common 3D printed jewelry objects. Wax 3D printing and lost wax casting are techniques used to produce sterling silver models. 3D printed sterling silver models can be finished with gloss, high gloss, antique, sandblasted, or satin finishing.

Steel 3D printed models are printed in steel powder infused with bronze. Steel is the most affordable form of metal printing and is very strong and suitable for very large objects. It is most typically used to produce fully functional parts, spare parts, and jewelry. The 3D Printing technique used with steel involves binding layers of steel powder together. Finishing choices include unpolished, natural polish, gold-plated polish, unpolished gold-plating, black polish, unpolished black, or brown polish.

Titanium 3D printed models are printed in titanium powder sintered together by a laser to produce end-use metal parts that are equally good as machined models. 3D printed titanium is a bit grayer and more matte with a slightly rougher and less defined surface than traditional shiny milled titanium. 3D printed titanium models are robust, precise, and as small as 0.25 mm. They are ideal for 3D printing of fully functional parts, spare parts, and jewelry. The two main 3D Printing techniques for titanium are Direct Metal Laser Sintering (DMLS) and Select Laser Melting (SLM).

Get multiple quotes for your parts in seconds