Modeling in Manatee

Set up Electric machine and drive models for simulation

Modeling Electric Drives in Manatee

Manatee software offers predefined and customizable multiphysics workflows for e-NVH simulations, catering to various stages of electric drive development at concept and preliminary design stages. These workflows can be tailored to specific engineering needs, supporting single-speed, variable-speed, and torque-speed plane simulations. Manatee enables quick setup for multiple electrical machine types, with templates and customization options for magnetic circuit geometry. The tool supports .dxf imports for custom slot and magnet shapes, allowing detailed geometric modeling. This flexibility is crucial for optimizing performance and minimizing electromagnetic noise in real-life lamination geometries. Manatee's user-friendly interface and shareable files facilitate collaboration among electrical, mechanical, and NVH engineers, streamlining the development process.

Quick e-NVH Simulation Definition

- Predefined and User-Defined Multiphysics Workflows

- Fast Electrical Machine Set-Up

- User-Defined Slot Shape Import From .dxf

- Magnet Shape .dxf Import

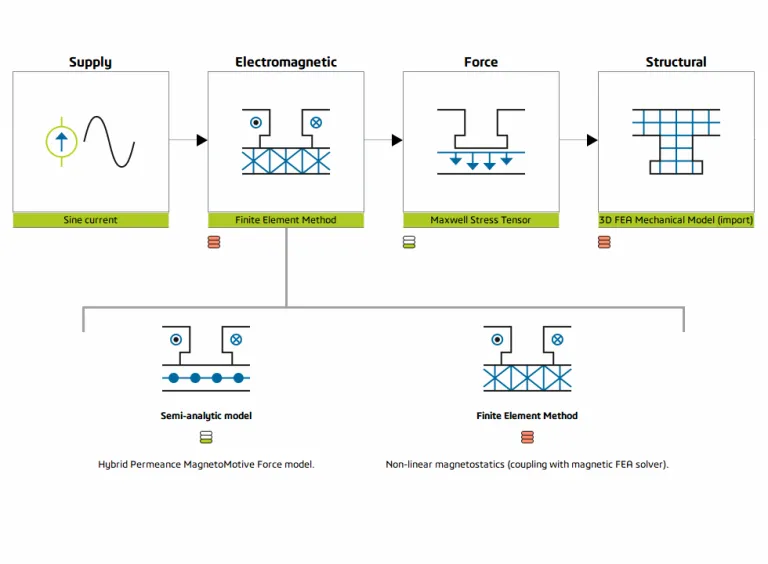

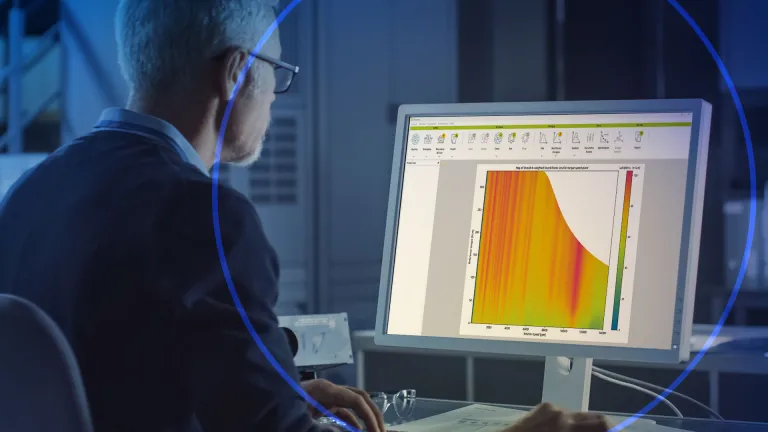

Predefined and User-Defined Multiphysics Workflows

Manatee offers default workflows for multiphysics simulations tailored to electric drives' V-model development cycle stage. Users can also create custom workflows.

Each workflow can be run for:

- Single-speed simulation (e.g., simulating network-fed electrical machines or checking single operating points)

- Variable-speed simulation (e.g., studying noise and vibrations along the torque-speed curve)

- Torque-speed plane simulation (e.g., analyzing resonances at partial load levels)

Predefined workflows are based on extensive consulting experience, while user-defined workflows allow customization of physics models to optimize computing time. These workflows can be combined with Manatee and other tools for optimal design trade-offs. Simulations can be set up and launched quickly by any engineer, and the flexibility to create custom workflows allows adaptation to specific engineering practices, speeding up the development cycle.

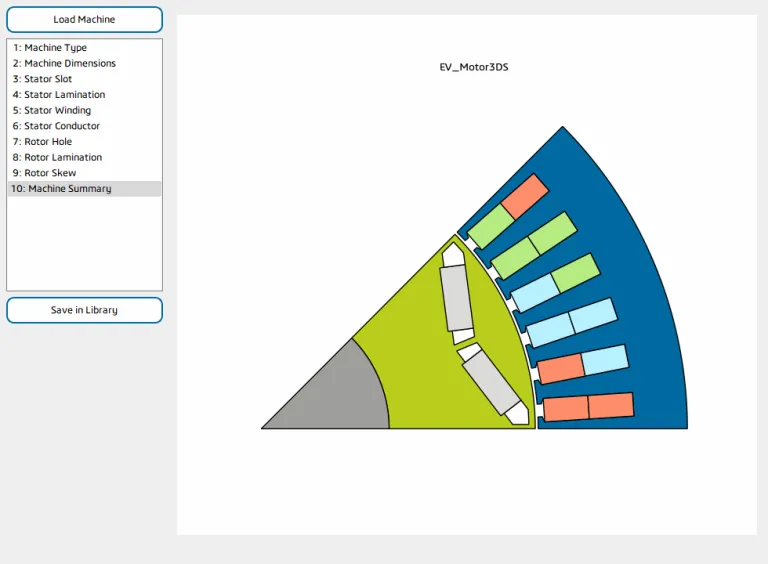

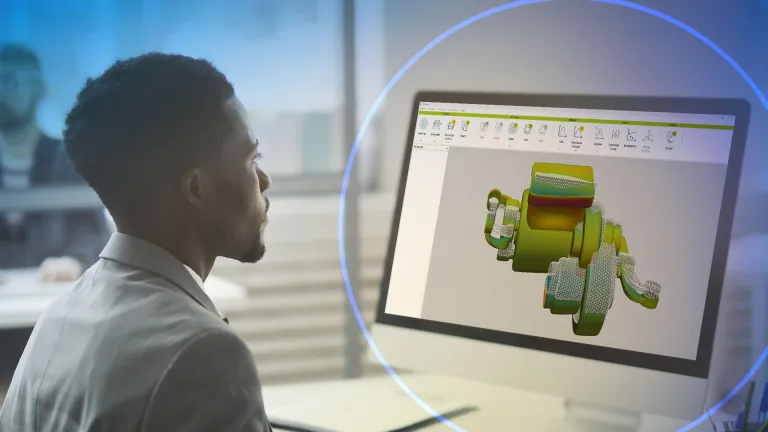

Fast Electrical Machine Set-Up

Manatee allows for the quick definition of various electric machine types:

- Interior and surface permanent magnet synchronous machines (IPMSM and SPMSM)

- Wound rotor synchronous machines (WRSM), also known as Externally Excited Synchronous Machines (EESM)

- Induction machines (SCIM)

- Outer rotor PM machines

Manatee includes a comprehensive set of templates for defining the magnetic circuit geometry, with predefined slot and magnet shapes for topology parameter sweeps. The winding pattern is automatically defined using the star of slot method, and special geometries can be imported via .dxf files.

Several topological features can be easily defined:

- Various skew patterns (linear, V-shape, zig-zag, or user-defined)

- Uneven pole distribution for SPMSM and IPMSM

- Ventilation ducts, notches, and keys can be added to the stator and/or rotor bores, either parametrized or via .dxf import

Manatee also provides predefined electrical machines for validation purposes. The software enables quick setup of the magnetic circuit by both electrical and mechanical/NVH engineers using a limited number of input parameters. Machine files are saved as .json files for easy sharing and collaboration.

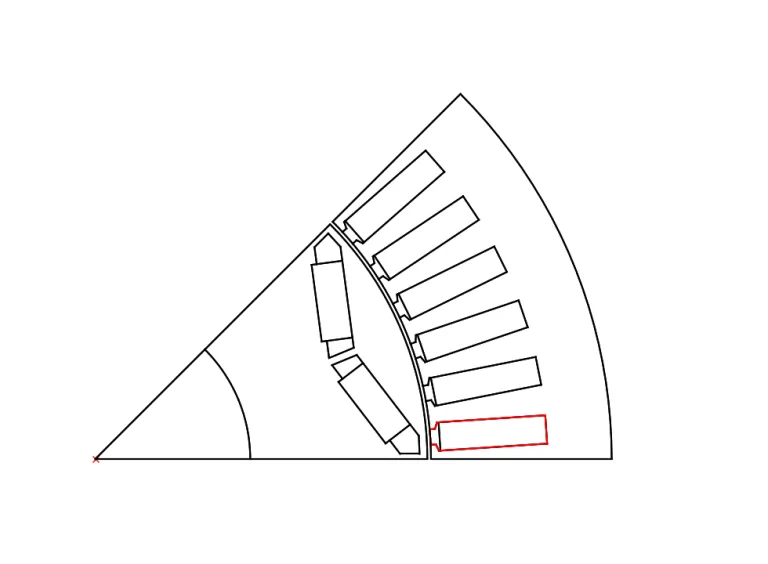

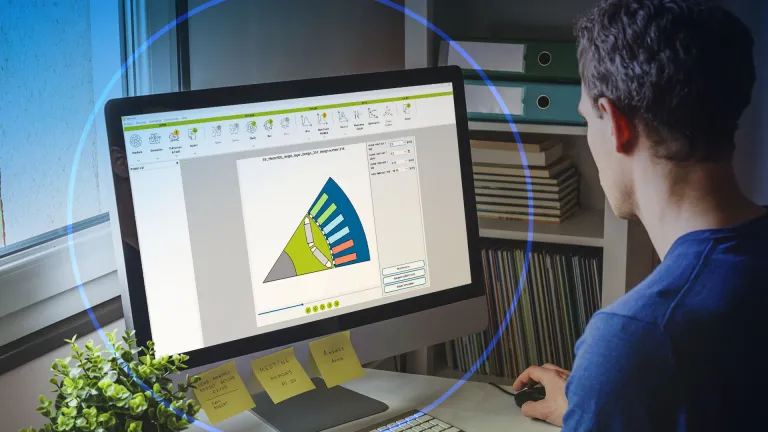

User-Defined Slot Shape Import From .DXF

In Manatee software, you can define the slot of your electrical machine either with predefined templates or with user-defined slot shape import from .dxf files. Once the .dxf file is imported, you can define your slot & winding with a few clicks by selecting relevant lines and points. Even with a user-defined slot shape, Manatee can change the winding number of layers, the winding pattern and the number of slots of your electrical machine (Manatee includes an automated winding algorithm based on Star of Slot method).

This .dxf import feature can be used by all engineers involved in the design of electrical machines, including electrical and mechanical engineers. Manatee can model lamination geometries coming from real-life, industrial CAD models.

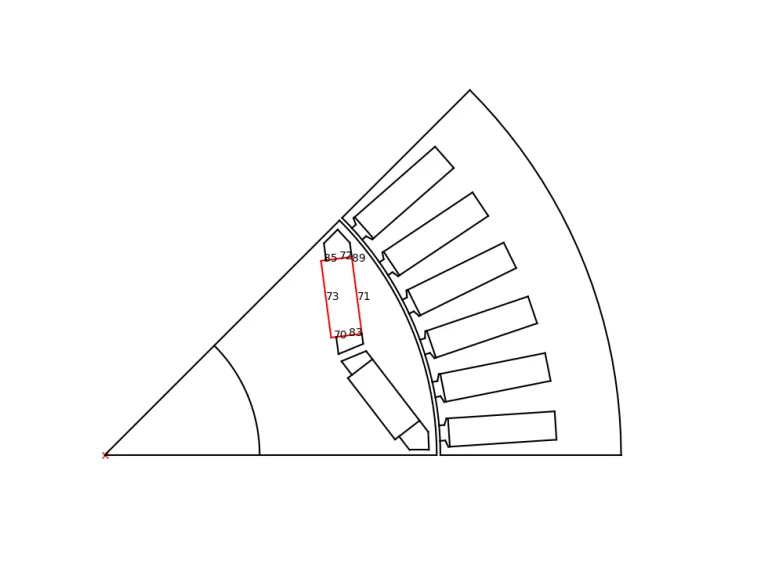

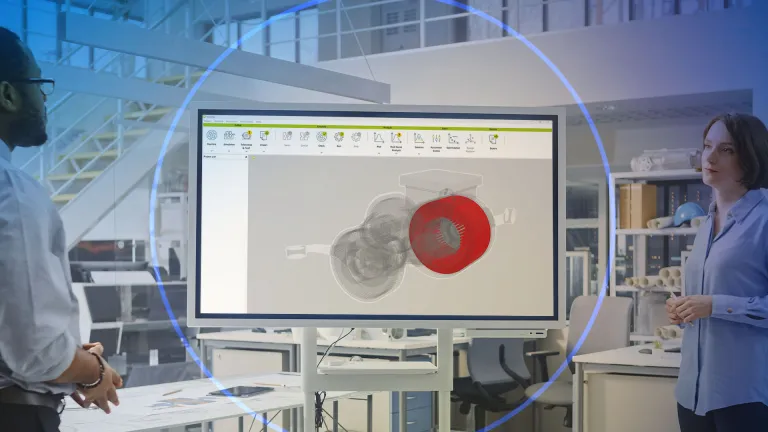

Magnet Shape .dxf Import

In Manatee software, the magnetic circuit of electrical machines can be quickly drawn either with predefined templates or with user-defined magnet shape .dxf import. This is particularly useful to include geometric details (air pockets due to rivets, bolts, or cooling ducts) that influence magnetic field distribution.

Once the .dxf file has been imported in the machine library, you can apply a scaling factor and define your holes & magnets with a few clicks by selecting lines and points, especially the magnetization direction.

The design of rotor lamination has several objectives such as minimizing hoop stress, maximizing cooling efficiency, maximizing torque, minimizing electromagnetic noise etc. This often leads to complex geometries for interior magnet pockets and bridges, which must be taken into account in e-NVH simulations according to consulting experience.

In Manatee software, any engineer can set up a machine geometry with a few clicks using .dxf file import and predefined templates. In the video below, it is shown how to define holes and magnets simply using the .dxf file import feature, with an example based on an IPMSM. This feature is essential to studying real lamination geometries coming from industrial CAD models.

FAQs about Modeling in Manatee

Manatee 2025x for the e-NVH simulation of electric machine and drives can run internal electromagnetic calculations on the following radial flux machines: Surface Permanent Magnet Synchronous Machines (SPMSM with internal or external rotor), Interior Permanent Magnet Synchronous Machines (IPMSM), Externally Excited Synchronous Machines (EESM, also called Wound Rotor Synchronous Machines) and Squirrel Cage Induction Machines (SCIM). The airgap flux import feature of Manatee allows extending magnetic noise & vibration calculations to other topologies such as Synchronous Reluctance Machines, Switched Reluctance Machines or Doubly Fed Induction Machine. Please contact Manatee support for other topologies, some workarounds may be available.

Manatee 2025x can calculates magnetic noise & vibrations produced by external rotor (outrunner) machines. Magnetic forces are computed both in stator and rotor frames. Magnetic Frequency Signature Analysis tool (MFSA) also includes the possibility to visualize the frequencies and wavenumber of Maxwell forces in both reference frames.

Manatee 2025x does not have import features for electrical machines, which means they must be redefined in Manatee GUI. This allows to define a fully parametric model, making it easier to explore alternative designs with parameter sweeps or optimization. Future release of Manatee will include import feature from CST and Opera.

Manatee 2025x includes the possibility to model rotor skewing with many different skew pattern (step skew, V-shape skew, continuous skew, user-defined skew). The change of magnetic forces along the rotor axis is then taken into account, resulting in the excitation of new structural modes. Magnetic forces along stator and rotor structure can be visualized with the Operational Force Shape visualization tool.

Parasitic axial forces introduced by non symmetrical skew patterns is not included in Manatee 2025x.

Manatee comes with a multiphysic material library which is used for magnetics & structural dynamics models. B(H) curves and magnet properties are important for magnetic calculations. Young Modulus is used in analytical and semi-analytical stator vibration models.

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering