MODSIM Unified Modeling & Simulation

MODeling & SIMulation on the 3DEXPERIENCE platform

What is MODSIM?

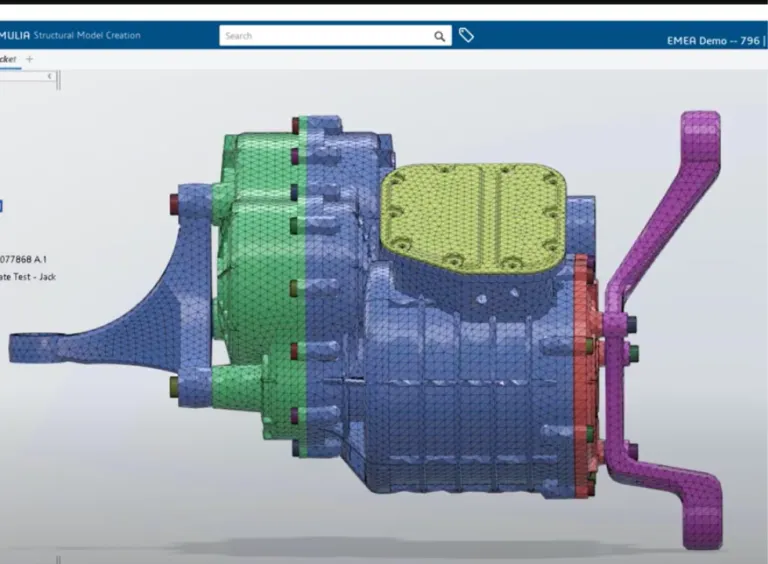

MODSIM unifies modeling and simulation on a common data model within a single user experience on the 3DEXPERIENCE® platform. In contrast to the traditional CAE processes, the MODSIM processes are cyclical rather than linear. In a MODSIM loop, modeling processes such as geometry cleanup, meshing, connections, and simulation processes, such as adding initial conditions, interaction, and boundary conditions, are performed without ever exporting the data. Instead, it is done by enriching the data at various stages. Thus, in a MODSIM loop, the simulations are updated automatically if there are any changes to the initial design. This is revolutionary compared to the traditional process, where you may have to start over. In addition, design exploration through the automation of parametric design space is an integral part of MODSIM core processes. It allows for what-if studies and has a significant impact on efficiency savings.

The 3DEXPERIENCE platform integrates data, systems, processes and people in one place. The platform is the single source of truth where companies can have well-defined and interoperable layers of product development like program management, product management and test management that work together with MODSIM. MODSIM on the 3DEXPERIENCE platform is the key enabler for:

- Simulation Process Transformation – A radical change towards well-documented processes that are automated, and integrated.

- Digital Engineering Transformation – Create a more desirable product by making your engineering more accelerated, innovative and efficient.

Key Benefits of MODSIM

Faster Time to Market

Dramatically reduce development time by upto 90% and from months to weeks

Reduce Late-Stage Failures

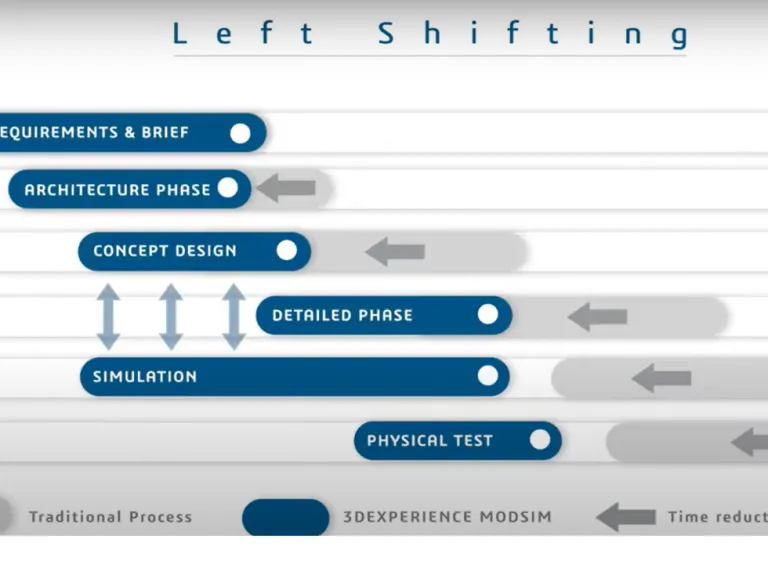

MODSIM enables a simulation-empowered shift-left strategy that pulls verification and validation upfront in the design concept stage and reduces the risk of late-stage failures and reworks.

Accelerate Innovation

By embedding simulation within the design process engineers can accurately predict product behavior. Automating the design exploration space with multiple iterations reduces uncertainty.

Reduce Cost

See significant improvement in product efficiencies of up to 40%, achieve weight savings of up to 20%, and reduce the capex cost of up to 8%

A Common Data Model

You can maximize your design process using advanced simulation tools such as Abaqus, PowerFLOW, and CST Studio Suite within your familiar design environment, like CATIA, SOLIDWORKS, and other popular CAD systems.

With MODSIM processes, you can embed requirements, design intent, and even your thought process directly into the design itself, allowing you to capture and replicate your design and simulation processes easily. MODSIM unifies the data model behind CAD and CAE, eliminating the need to export or convert models for simulations.

It is also seamlessly integrated with the PLM system, enabling efficient collaboration with partners, suppliers, and consultants for significant efficiency savings over disconnected legacy systems.

Multidisciplinary Collaboration

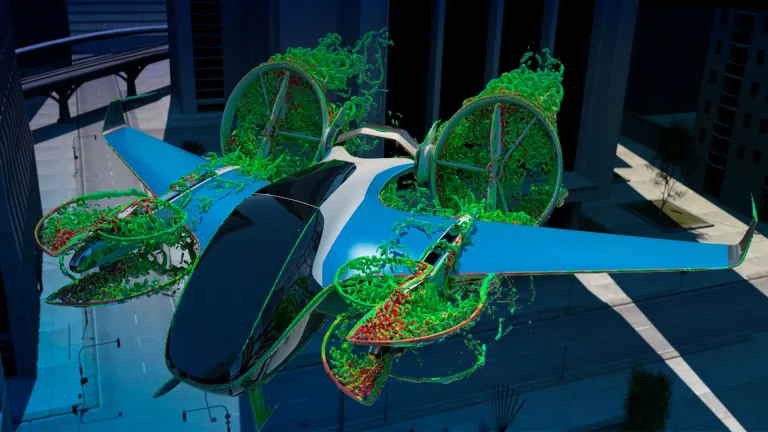

The MODSIM process, available on the 3DEXPERIENCE platform, designs and simulates, bridging the gaps between engineering disciplines and enabling truly integrated multiphysics simulations. With the SIMULIA portfolio covering a wide range of physical behaviors such as structural, fluid, electromagnetics, acoustics, and multibody systems, MODSIM allows for simulations that consider the interactions of these different physical aspects, providing an accurate representation of the true behavior.

SIMULIA provides project management capabilities that offer insight and confidence, as well as transparency and traceability across the design process. This includes the ability to track issues, manage changes, and access work in progress at any time. With MODSIM and the 3DEXPERIENCE platform, teams can validate their designs on the fly, enabling efficient and effective project management.

Shift-Left Strategy

MODSIM enables a simulation-empowered shift-left strategy that pulls verification and validation upfront in the design concept stage and reduces the risk of late-stage failures and reworks.

Concept Structure Engineers allow designers to run simulations as the product develops. The lattice designer creates simulation-aware geometry, moving away from traditional geometry into something that is ready for simulation upfront. These concepts help achieve massive efficiency gains and deliver innovative products on time at a lower cost with less prototyping.

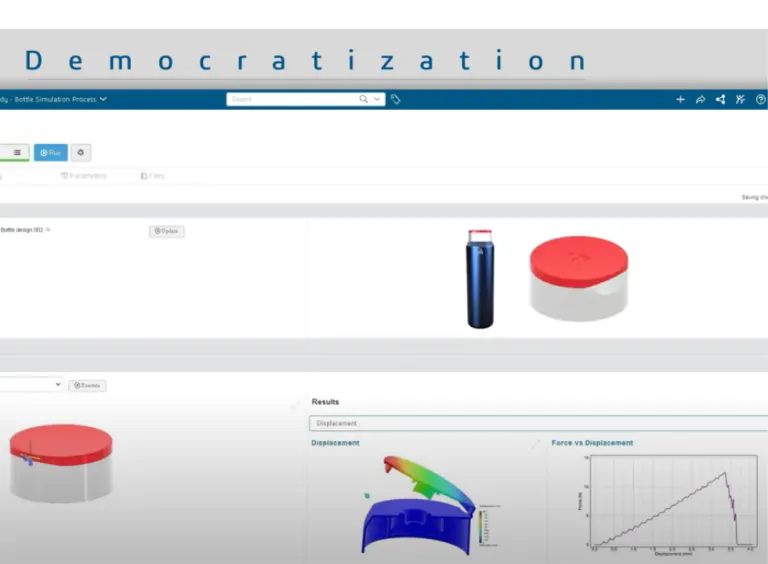

Democratization of Simulation

Democratize simulation and make even complex simulation workflows available to designers and non-experts on the 3DEXPERIENCE platform to speed up the design process.

High-value simulation workflows can be standardized and templatized to allow consistent, repeated use of high-quality simulation best practices. This also frees up the simulation experts to focus on higher-value work.

- MODSIM for Engineers

- MODSIM for Teams

- MODSIM for Businesses

MODSIM for Engineers

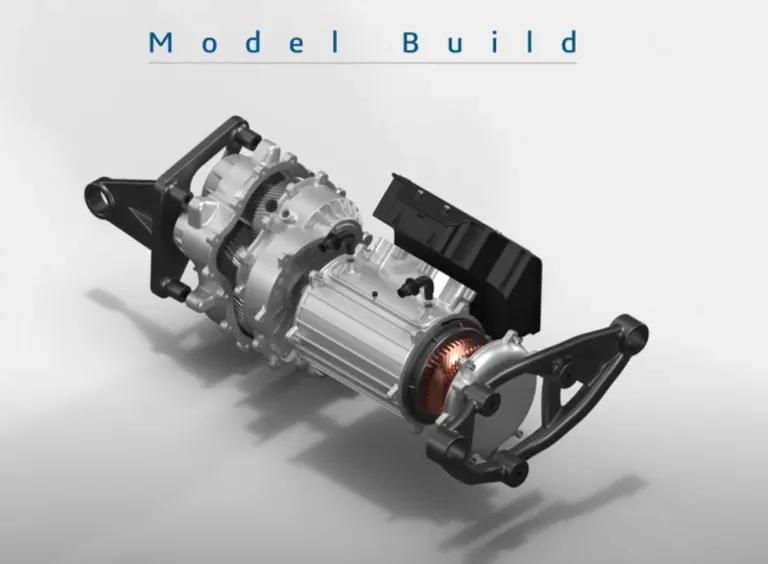

MODSIM on the Dassault Systemes 3DEXPERIENCE platform is a unique next-generation engineering and design paradigm that unifies modeling and simulation. In this e-book, we explain some of the benefits experienced by a fictional electric drive development team using MODSIM, including:

- Common model build

- Automated modeling

- Design in your comfort zone

- Automatic simulation set-up

- Democratization

- Single source of truth

- Platform integration

MODSIM for Teams

Engineering team leaders manage cross-disciplinary teams and find it difficult to remove silos between departments, get real-time updates, and lack visibility to required data to make informed decisions. They often face conflicting requirements and must deliver innovative products on time. The MODSIM approach brings your multidisciplinary team of experts, non-experts and managers to help realize the value of looking at the design process as a whole. Explore the full benefits of MODSIM now.

MODSIM for Businesses

Discover how the 3DEXPERIENCE platform enhances product development. With MODSIM, businesses can reduce prototyping costs and risks by integrating simulation early in the design process. This leads to fewer redesigns, successful certification, and faster market entry.

Simulation Processes Automation

- Automated Design Updates

- Parametric Design Space Exploration

- Integrated Simulation Process Flow

Automated Design Updates

MODSIM process automates design updates so you don’t have to start over and previous designs can be repurposed to create a family of products. The animation here shows how an extreme design change from performance to mass-market electric motor is done almost automatically with little interference. We start with a vehicle requirement at a high level. It is cascaded down to system requirements for the electric drive unit. We then cascaded those down further to the system model parameters for the e-drive unit, and then we updated our model, which updates our simulation, and that updated our test outcome. The test outcome will go back to the product manager who will update the vehicle requirements. This workflow also uses out-of-the-box automated simulation templates that can be used by the designer with little or no simulation expertise.

Parametric Design Space Exploration

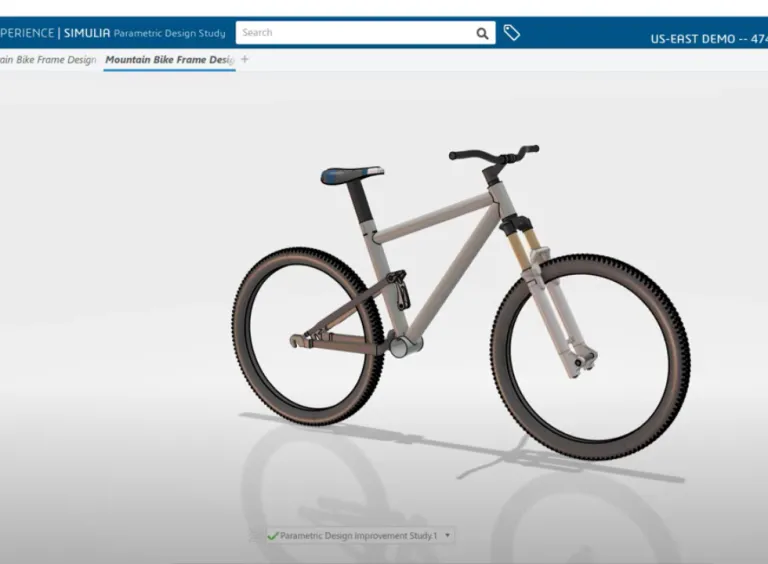

With products becoming more complex, the faster you can validate your product by simulation, the more time you’ll have to find the best innovative technical solution. MODSIM offers a unique opportunity for parametric design space exploration. Users can get an optimized design by simply specifying the design variable and defining the design space. The system autonomously constructs all points within the design space and conducts simulations to identify the most optimal design. The example shows how a bicycle is optimized for stiffness with a few simple clicks because MODSIM processes have automated parametric design space.

Integrated Simulation Process Flow

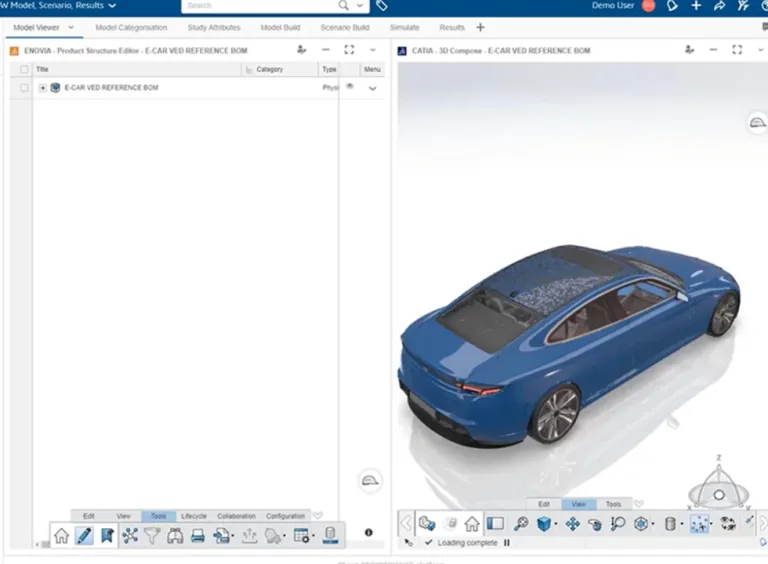

MODSIM is the most efficient way of doing modeling and simulation. It is fully integrated and goes beyond CAD-CAE associativity. We can deliver processes that are more collaborative, democratized and we can have BOM connected CAE. The integration also includes the pre and post-process of CAE. This allows more saving as all the data you may need to do the simulation and all the result data are in one place. The attached video shows how a full vehicle powerflow simulation is democratized and connected to engineering BOM.

Digital Engineering Transformation

- Accelerated Product Development

- Innovative Concept Development

- Efficiency Through Systematic Democratized Simulations

Accelerated Product Development

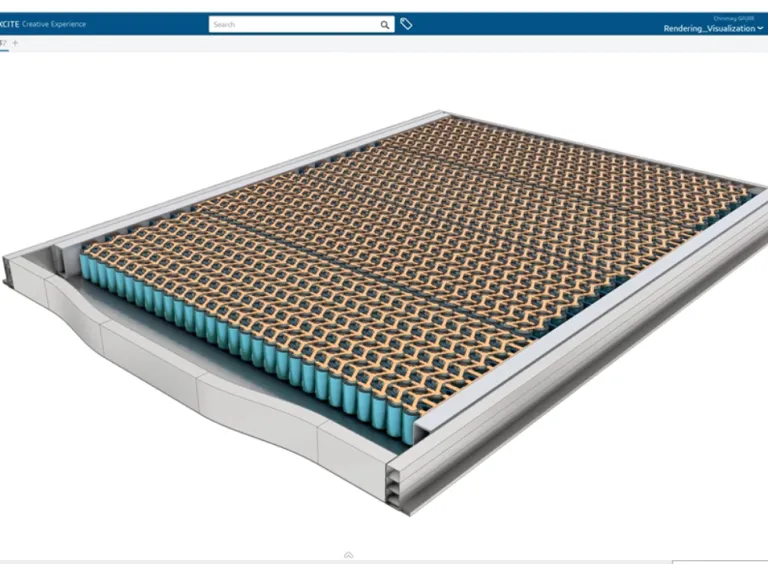

The most obvious impact of implementing the MODSIM-based process is that it completely automates previously manual tasks, meaning that they can be done more rapidly. For example, we can dramatically accelerate automated processes and reduce the development time of a battery pack for a new electric vehicle.

The streamlined MODSIM process accelerates the development of battery pack design across different platforms, regions and cell types using a parametrized system model and advanced apps within the 3DEXPERIENCE platform, such as Layered Product Design, Material Homogenization, Concept Structure Engineering and Visual Scripting.

Innovative Concept Development

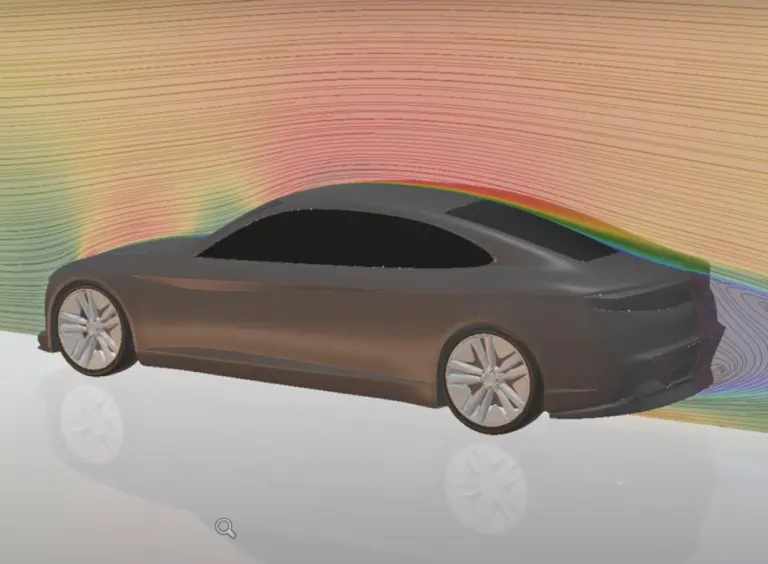

MODSIM processes allow designers to be more thoughtful and creative in their design. A designer can create and validate a design in the concept phase on the 3DEXPERIENCE platform using CATIA and SIMULIA apps. CATIA tools like Imagine and Shape and Natural Sketch allow engineers not only to sketch effortlessly but at the end of it also to have a CAE-ready model without any additional work. Designers can validate their designs and do feasibility studies in the early concept phase when combined with advanced but intuitive simulation apps. The designer can easily run advanced fluid simulations to study the aerodynamic impact. It also allows designers to build structure models using module libraries and run structure simulations to check bending, stiffness, crash impact etc, on the design.

MODSIM empowers designers to confidently create innovative designs, providing them the assurance they need for feasibility.

Efficiency Through Systematic Democratized Simulations

MODSIM processes allow designers and engineers to be more efficient by allowing them to work on the same data, share, collaborate, validate and verify their designs all seamlessly in the same environment. Is it possible to scale the MODSIM process of automatic model selection and creation, automated updates, traceability, reuse, and lifecycle management to tens of thousands of processes and how. The answer is yes; we can use a systematic simulation system that is automated and democratized. We have done this with the help of a widget that is connected and driven by the engineering BOM and can create a standardized view for simulation across groups, departments and teams. We have proven results that our system performs successfully even with drastic design change. We noticed that as we built the system to include more processes, the reusability, traceability, and lifecycle management were all dealt with automatically. This system can be used of Artificial Intelligence and Machine Learning making your design and engineering future ready.

MODSIM - Where to Find It?

- MODSIM with CATIA

- MODSIM with SOLIDWORKS

- MODSIM with CATIA V5

MODSIM with CATIA

CATIA shifts expectations from traditional 3D CAD (computer‑aided design) to cognitive augmented design, which fuses modeling and simulation.

By leveraging knowledge, know‑how, and proven technology to automate design, CATIA supports a performance-driven design approach from the concept phase onward. This powerful combination can help companies successfully execute their innovation strategies and shape more sustainable, market-leading products.

MODSIM with SOLIDWORKS

MODSIM unifies modeling and simulation on a common data model within a single-user experience on the 3DEXPERIENCE® platform. The goal is to consider the whole product development process and break down existing departmental silos.

MODSIM is more than a simulation-driven design. It enables simulation to drive the entire product development process from beginning to end, from requirements to architecture, validation to certification, and product development to program management, including design exploration, processes, automation, change management, and collaboration.

MODSIM with CATIA V5

The design and engineering landscape is evolving rapidly. How can you accelerate the product development process by leveraging CATIA V5 and leveraging the MODSIM approach?

With cloud services, you can extend the performance of CATIA V5, improve collaboration, and ultimately accelerate time to market without disrupting your processes.

Customer Testimonials

Learn how leading companies are using SIMULIA MODSIM solutions to streamlining design and engineering processes

The continuous pursuit of cleaner cars and much shorter development timescales demands a much closer integration between CAD and CAE and a greater confidence in the CAE predictions. At Jaguar Land Rover, we have invested heavily in the deployment of 3DEXPERIENCE as the backbone for engineering as we believe that this platform will give us the close integration and confidence in simulation that we need.

Start Your Journey

The world of unified Modeling and Simulation is changing. Discover how to stay a step ahead with SIMULIA.

FAQs About MODSIM

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering