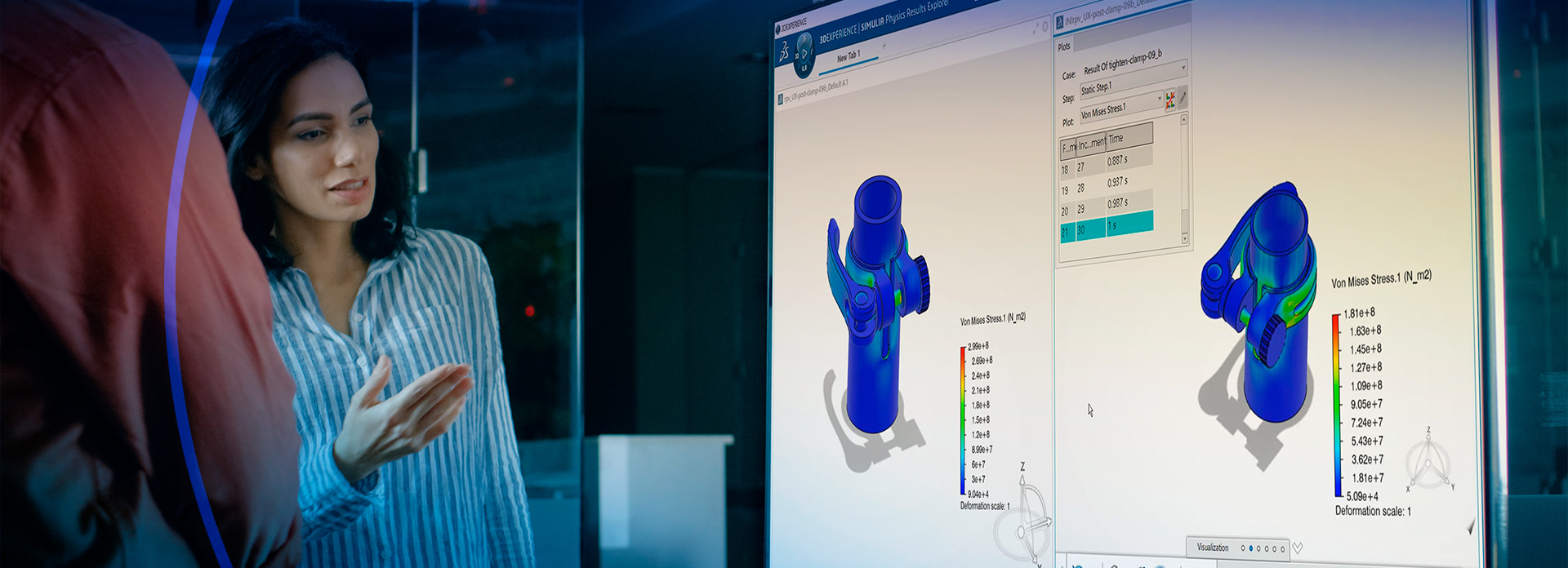

Structural Simulation

Finite Element Analysis for Mechanical and Civil Engineering

Advanced Structural Simulation Technology

Structural simulation using the Finite Element Method (FEM) and related technologies, offers a deep understanding of how products, assemblies, and processes respond to real-world conditions, including varying loads and temperature.

SIMULIA's structural simulation technology enables the creation of virtual prototypes, enabling the comprehensive evaluation of crucial performance indicators instead of relying on physical testing.

These indicators include stiffness, ensuring deformation is acceptable under normal use, and strength, upholding structural integrity even under the maximum design loads.

Safety guarantees predictable failure modes to protect consumers and bystanders. Durability/reliability ensures a consistent and predictable product lifespan, and robustness maintains performance consistency throughout design and manufacturing phases.

Adherence to industry standards for noise and vibration delivers a superior user experience, comfort assures positive interactions between humans and the product or process.

SIMULIA Structural Simulation Key Benefits

Accurate Predictions

Gain precise real-world structural insights of products under a wide range of loading conditions using Abaqus and fe-safe technologies.

Enhanced Product Quality

Achieve cost-efficiency and design issue prevention through early-stage structural simulations in a user-friendly interface integrated with CATIA or SOLIDWORKS design geometry.

Cost-efficient Prototyping

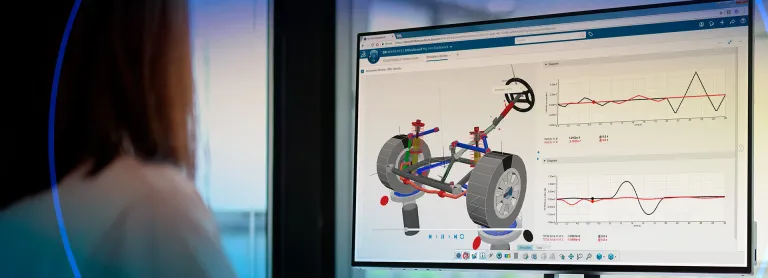

Virtual testing and simulation save costs and expedite time-to-market, covering everything from component analysis to complex assembly simulations with nonlinearities.

Strategic Impact of Structural Simulation

Structural simulation plays a pivotal role in achieving key business objectives, reducing risks, ensuring compliance with standards, and reducing time to market. Structural Simulation software enables users to:

- Minimize product complexity and cost

- Minimize risks of failure

- Optimize competitive positioning

- Satisfy corporate or government standards

- Accelerating product launches

Finite Element Analysis (FEA)-Driven design insights reduce costs, eliminate errors, and shorten design cycles. Unlike typical prototype testing, virtual prototypes can tell you much more than pass/fail. It can tell you why a part can fail and can help you understand whether your improvements can prevent it from failing. And unlike physical testing, mechanical simulation is available 24/7/365.

SIMULIA Structural Analysis Technologies

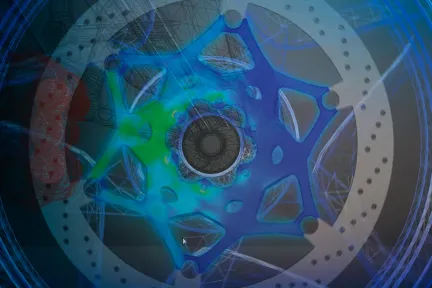

The SIMULIA portfolio in the Structures domain includes products on the 3DEXPERIENCE platform, which are available on cloud, along with Abaqus, fe-safe, and Tosca Structure technologies. Abaqus is a market- and technology-leader in linear and nonlinear finite element analysis. Both implicit and explicit solution techniques are available and are complementary. fe-safe technology provides modern algorithms for durability and fatigue lifecycle predictions. Tosca Structure technology enables optimization of the 3D shape and topology of your part to reduce weight and improve strength and stiffness. These technologies are popular for their power, flexibility, feature set, and solution performance on modern High-Performance Computing (HPC) architectures including GPUs and Cloud.

SIMULIA Structural Simulation Software Products

Finite Element Analysis for Mechanical Engineering and Civil Engineering

Durability Analysis Software for Finite Element Models

Efficient Optimization Based on FEA and CFD Simulations

SIMULIA Structural Simulation Software on 3DEXPERIENCE Platform

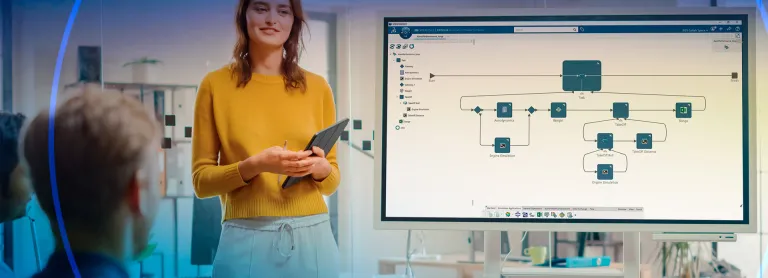

SIMULIA Structural Simulation software products are packaged as Roles on the 3DEXPERIENCE platform to get you up to speed faster and work more efficiently with all needed applications available at your fingertips. Select a package that corresponds to your role in an organization.

Start Your Journey

Explore the technological advancements, innovative methodologies, and evolving industry demands that are reshaping the world of structural analysis and simulation. Stay a step ahead with SIMULIA. Discover now.

FAQs About Structural Analysis Program & Software

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering