Manatee

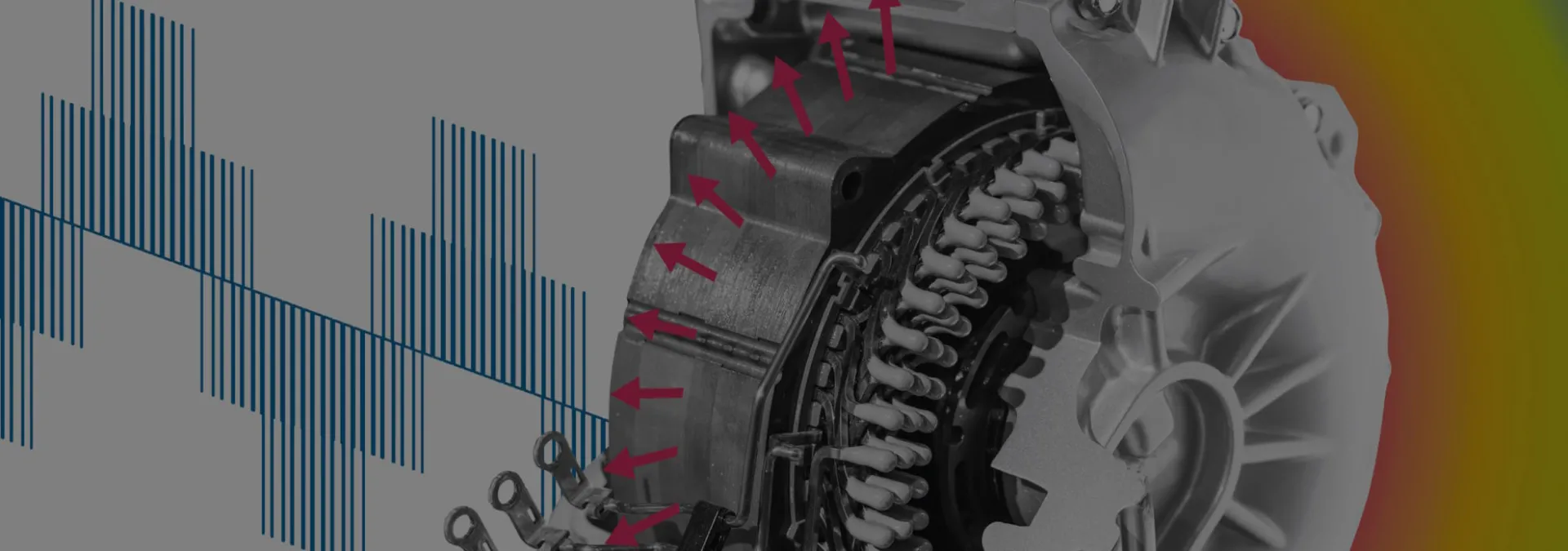

Control Magnetic Noise & Vibrations of Electric Machines and Drives from Concept to Preliminary Design Phase

What is Manatee?

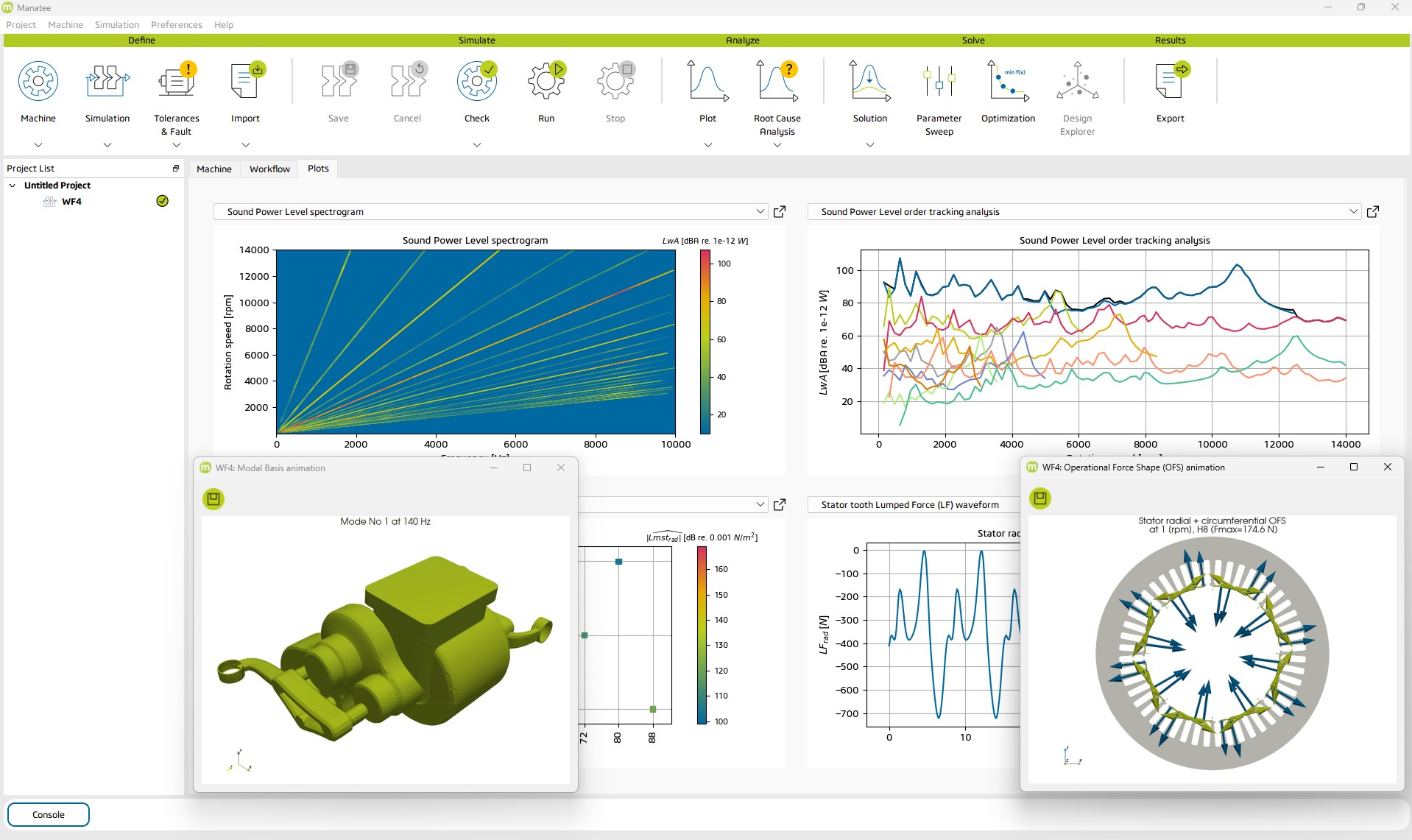

Manatee offers a collaborative simulation and analysis environment designed to quickly and accurately optimize the vibroacoustic performance of electric machines and drives under electromagnetic excitations. Its user-friendly interface has been developed for control, electrical, mechanical and NVH engineers.

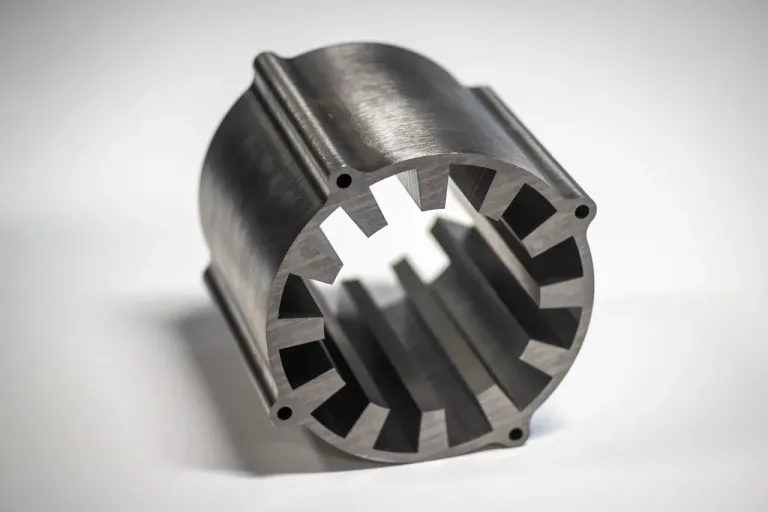

Designing high-quality electric machines requires controlling their acoustic noise and vibration levels at every development stage, from risk analysis in preliminary studies to vibroacoustic troubleshooting after prototype manufacturing. Electric machines can induce significant electromagnetic noise and vibration (e-NVH) due to Maxwell force excitations, resulting in sound levels going up to 125 dBA at 1 meter. All topologies of electric machines can produce health, comfort, environmental friendliness or mechanical fatigue.

Electrical, magnetic and mechanical early design choices can have up to ±20 dB impact on magnetic noise and vibration levels. However, the prototyping and testing of electric machines are expensive and time-consuming. Manatee virtual prototyping environment increases design productivity and physical insights, optimized electromagnetic and vibroacoustic performance and shorter development cycles.

Key Benefits of Manatee NVH Applications

Fast

Set up multiphysics simulation with a button click using predefined workflows adapted to each engineering profile.

Define, run your simulation and visualize your calculation results in the same environment within minutes.

Accurate

Use state-of-the-art calculation methods throughout the development lifecycle, from concept to preliminary design phase.

Include the effect of manufacturing tolerances on carrying out a robust e-NVH ranking of electric machines.

Insightful

Understand the root cause of magnetic noise and vibration using advanced visualization tools.

Run “what if” scenarios using powerful parameter sweeps and optimization tools, easily compare simulation results and explore the whole design space.

Collaborative

Explore the most relevant noise mitigation techniques combining control, electromagnetic, and structural design modifications.

Work in parallel with other engineering departments through a user-friendly Graphical User Interface.

NVH Simulation of Electric Machines for Electrical Engineers

Electrical engineers can assess and reduce magnetic noise and vibrations at different design stages using Manatee software.

In the early design stage, electrical engineers can compare different slot/pole combinations and electric machine topologies. They can estimate the risk of resonances using the frequency signature of magnetic forces provided by Magnetic Force Signature Analysis (MFSA).

Once the electrical machines are quickly set up under the Manatee environment, electrical engineers can either compute or import air gap flux. They can study the influence of electromagnetic design parameters on the sound power level radiated by the stator yoke using quick NVH models by running parameter sweeps or optimizations. They can analyze the tradeoffs between electromagnetic performances and NVH performances. In the detailed design phase, they can also assess the impact of current harmonics on e-NVH.

NVH Simulation of Electric Machines for Mechanical Engineers

Mechanical engineers can assess and reduce magnetic noise and vibrations at different design stages using Manatee software.

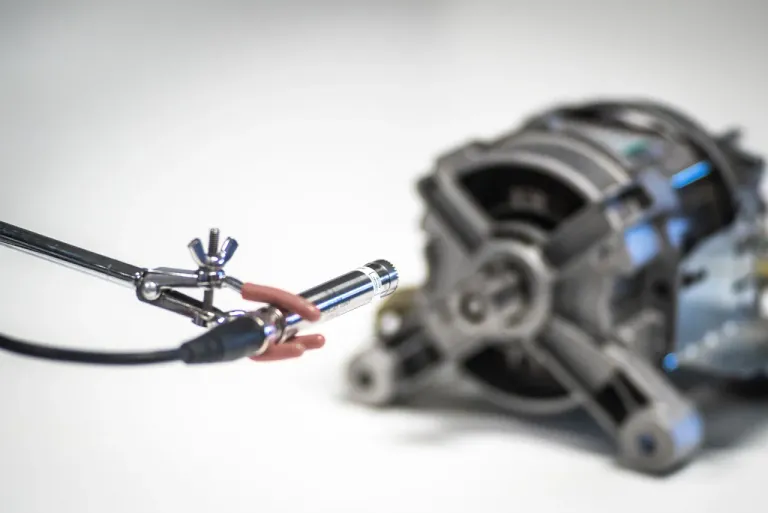

By importing modal bases from 3D FEA software, mechanical engineers can iterate on mechanical integration of the electric motor, stiffening some parts or moving some resonances at other operating points. Spectrograms and load case contribution plots ease the results analysis and the identification of which modes are excited by magnetic excitations.

Mechanical engineers can also study the impact of 3D eccentricity effects on noise and vibration to assess design robustness.

NVH Simulation of Electric Machines for Acoustical Engineers

Acoustical engineers can assess and reduce magnetic noise and vibrations at different design stages using Manatee software.

They can assess sound pressure and sound power levels based on fast acoustic models.

Acoustical engineers can also import external noise sources such as gear noise, to get a global estimation of “magnetic noise” + “external noise source”.

In addition, acoustical engineers can analyze sound quality metrics.

Discover the Capabilities of Manatee

Start Your Journey

The world of e-NVH is changing. Discover how to stay a step ahead with SIMULIA Manatee

FAQs About NVH Simulation Software & Solutions

e-NVH means electrical or electromagnetic Noise, Vibration, Harshness, so noise and vibration problems caused by electromagnetic forces, which may include electrostatic or magnetic forces. e-NVH issues can be due to passive components (inductors, transformers, capacitors, …) and electric machines (electric motors, generators, actuators…). SIMULIA offers several simulation workflows to tackle e-NVH problems, such as Manatee (specialized in rotating electric machines e-NVH analysis and mitigation) and CST Studio Suite x Abaqus x Wave6 combination (at the detailed design stage of all electrical systems).

NVH analysis or testing refers to the process of evaluating and understanding the Noise, Vibration, and Harshness characteristics of a product or system. It involves assessing the sources of noise and vibration, understanding how they propagate through the structure, and analyzing their impact on the overall user experience.

NVH simulation solution is vital in automotive (vehicles), aerospace, and consumer electronics industries because it:

- Optimizes product performance and comfort.

- Saves costs and time by replacing physical prototypes.

- Detects issues early in the design process.

- Ensures compliance with regulations.

- Provides a competitive advantage through superior product performance.

- Enables multi-disciplinary optimization for the best balance between NVH performance and other factors.

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering