Electromagnetic Compatibility Simulation

Virtually Test Compliance with EMC Standards

What is Electromagnetic Compatibility?

Electromagnetic compatibility (EMC) describes the ability of an electronic device to operate as intended in its environment without interfering with other devices. Controlling electromagnetic interference (EMI) is an integral part of the development of any electronic device. By law, products must comply with international EMC standards, which regulate EM emissions and the susceptibility of commercially available electrical and electronic systems. A successful product must strike a balance between EMC and competing design requirements such as size, cost and performance. Finding this balance can pose major challenges to engineers. The earlier we can identify a potential EMI problem, the less disruption it causes to the design process. By including EMC-compliant design at an early stage, additional costly development iterations can be avoided later on.

EMC Certification

Electromagnetic compatibility (EMC) regulations ensure that devices must not emit electromagnetic fields that can disrupt other electronics. Devices must also be able to withstand electromagnetic interference(EMI) from nearby devices and from environmental electromagnetic effects (E3) such as lightning strikes or electromagnetic pulses. To ensure compliance with these regulations, electronics products must undergo EMC testing and certification before they can be sold on the market. Certification not only demonstrates compliance with regulations but also assures customers that the electrical system will function properly in an electromagnetic environment.

Benefits of Early EMC-Compliant Design

By including EMC-compliant design at an early stage, engineers can save time and money by avoiding costly development iterations later on. It also allows for better overall design optimization as any potential EMC issues can be identified and addressed early on in the design process.

How can simulation help with EMC?

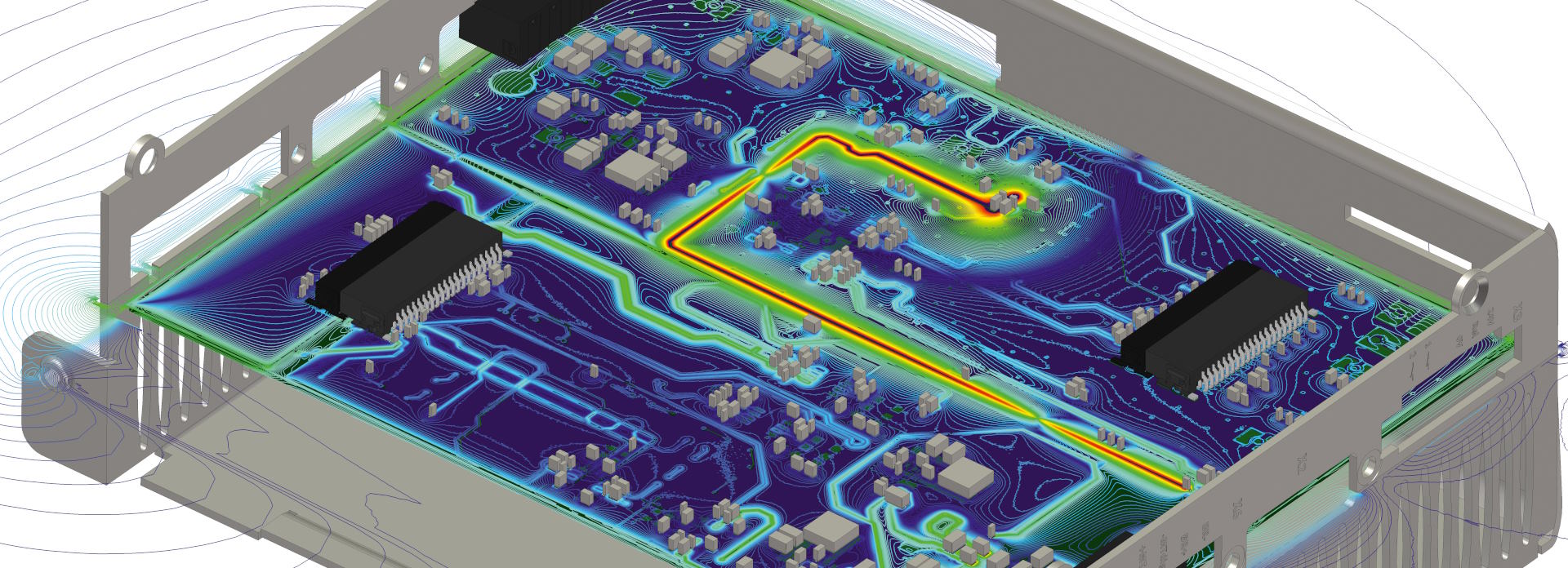

Electromagnetic simulation gives engineers a detailed view of all EMC-relevant aspects of a device – from the flow of currents across a circuit board, to the propagation of fields between co-site antennas. It helps them identify and resolve potential problems before testing. This not only cuts development time and costs, but can also reduce the risk of failing regulatory EMC testing, according to various standards such as MIL-STD. SIMULIA’s simulation portfolio includes a range of specialized tools for interference and EMC analysis, powered by fast, accurate 3D solvers.

EMC Software Applications:

- EMC Rule Checking

- EMC virtual testing

- Co-site interference analysis

- E3 - Electromagnetic Environmental Effects

- Cable harness simulation

With CST Studio Suite technology, the relevant EMC categories emissions and susceptibility can be studied. It also enables the investigation of system-level effects, either by its sheer ability to tackle very large and complex set-ups efficiently or by hybridization between the most appropriate solvers, dedicated to a certain problem class, such as cables for example.

EMC/EMI Applications

- Crosstalk and De-Sense

- Air Discharge Method

- Contact Discharge Method

- Bulk Current Injection

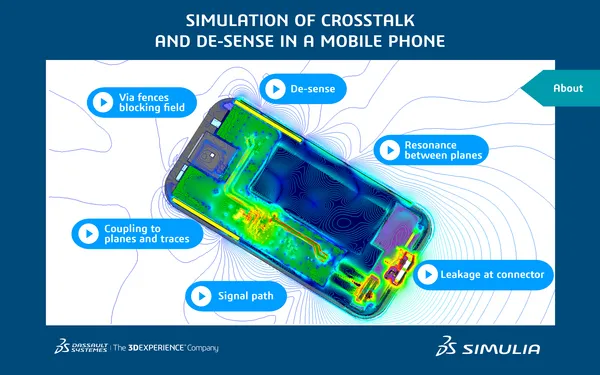

Simulation of Crosstalk and De-sense in a Mobile phone

This interactive infographic uses short videos to explain the electromagnetic compatibility (EMC) and signal integrity (SI) issues affecting the design of a mobile phone.

USB 3.2 offers data speed up to 20GBit/s. These fast signals create broadband noise that can affect other electronic systems even at radio frequencies (RF) and often leads to RF de-sense and crosstalk.

Electromagnetic simulation can be used to analyze the distribution of currents and electromagnetic fields inside devices, showing how they propagate and identifying the coupling paths that can cause interference issues. With this information, engineers can improve the routing of traces and add interference mitigation components such as via fences.

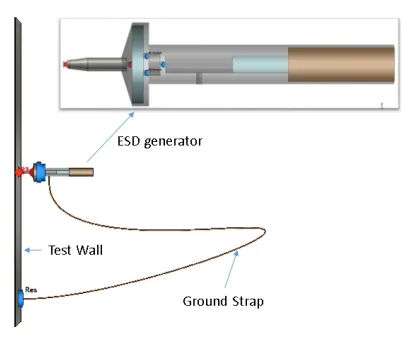

ESD Testing Simulation - Air Discharge Method

In the air discharge method, the charged electrode of the test generator is brought close to the device under test (DUT) and the discharge is actuated by a spark to the device. In this paper, the electrostatic discharge (ESD) generator test setup is modeled using SIMULIA CST Studio Suite and the simulations are carried out for different test levels for air discharge as specified in the IEC standard IEC 61000-4-2

ESD Testing Simulation - Contact Discharge Method

In the contact discharge method for electrostatic discharge testing, the electrode of the test generator is held in direct contact with a conducting part of the equipment under test (EUT). The discharge switch actuates the discharge within the generator. IEC 61000-4-2 describes the procedure for the calibration of the injected waveform by the ESD generator. We compare the waveform characteristics with the ideal generator waveform characteristics.

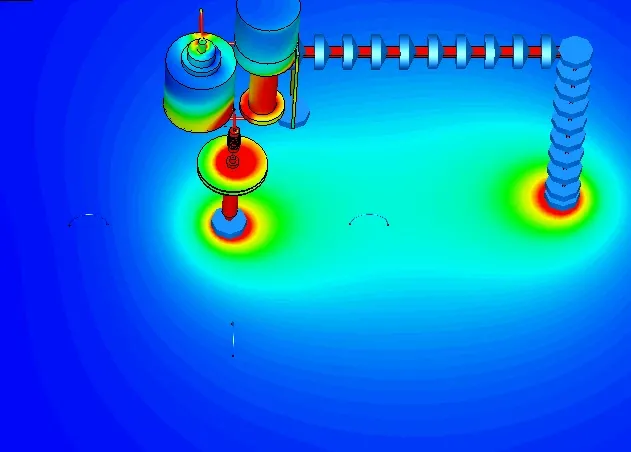

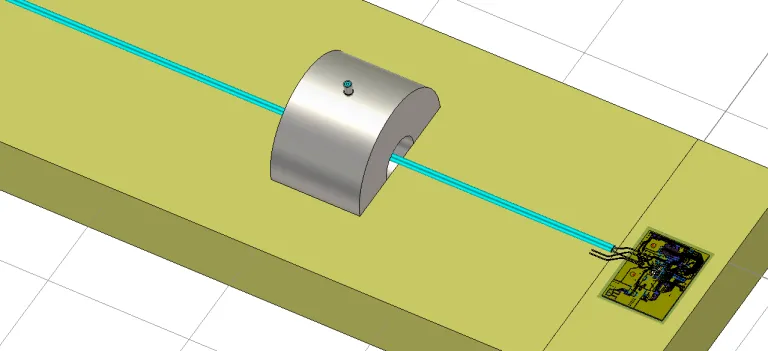

Bulk Current Injection

The Bulk Current Injection (BCI) technique, a non-invasive method to test the immunity of electronic devices. We use electromagnetic fields to couple a noise signal into the device.

Learn how to perform a simulation of the typical bulk current injection test.

Start Your Journey

Explore the technological advancements, innovative methodologies, and evolving industry demands that are reshaping the world of Electromagnetic Compatibility Simulation. Stay a step ahead with SIMULIA. Discover now.

FAQ about EMC & EMI

Electromagnetic Interference (EMI) refers to the disruption caused by electromagnetic fields, typically considered as noise, affecting the performance of an electronic device, leading to data loss or malfunction. There are various sources of EMI.

Electromagnetic Radiation (EMR) is the electromagnetic energy that is emitted or radiated from a source in the form of electromagnetic waves. Sources of EMR can be natural, for example the sun for solar radiation, man-made, by design for example in communication antennas, or involuntarily by radiofrequency emissions from electronic devices. In any case these are sources of EMI that can lead to disruptions of operation. In this sense, EMR is a phenomenon that disturbs the operation of an electromagnetic device.

The purpose of EMC testing is twofold. First, it assesses the electromagnetic interference (EMI) caused by a device, ensuring it won't disrupt the functionality of other devices within its electromagnetic environment.

Second, EMC testing evaluates a device's immunity to EMI, verifying that it can function correctly even when exposed to external electromagnetic disturbances or noise. This includes both common interferences, like devices operating in the same frequency range, and extreme scenarios, such as lightning strikes or electromagnetic pulses.

The goal of EMC testing is to achieve certification to proof that the device complies with the relevant standards set by regulatory bodies.

Electromagnetic Interference (EMI) is defined as degradation in the performance of equipment or transmission channel or a system caused by an electromagnetic disturbance (IEV 161-01-07)

Electromagnetic Compatibilty (EMC) is the ability of equipment or a system to function satisfactorily in its electromagnetic environment without introducing intolerable electromagnetic disturbances to anything in that environment (IEV 161-01-07)

EMC sets the rules and limits to prevent EMI for an electrical system. EMC testing assesses the susceptibility or immunity of devices as well as their radiated emissions, according to standards such as IEC, MIL-STD, CISPR or FCC part 15, for civil or military applications.

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering