PowerTHERM

PowerTHERM and PowerCOOL - A Complete Thermal Management Solution

Efficient Digital Thermal Solutions for Vehicles

Thermal analysis reveals the heating and cooling behavior of devices when in use, and is essential for ensuring that products operate reliably in real-world conditions. PowerFLOW supports rapid simulation of thermal management systems with two add-ons – PowerTHERM and PowerCOOL – for thermal analysis.

PowerTHERM

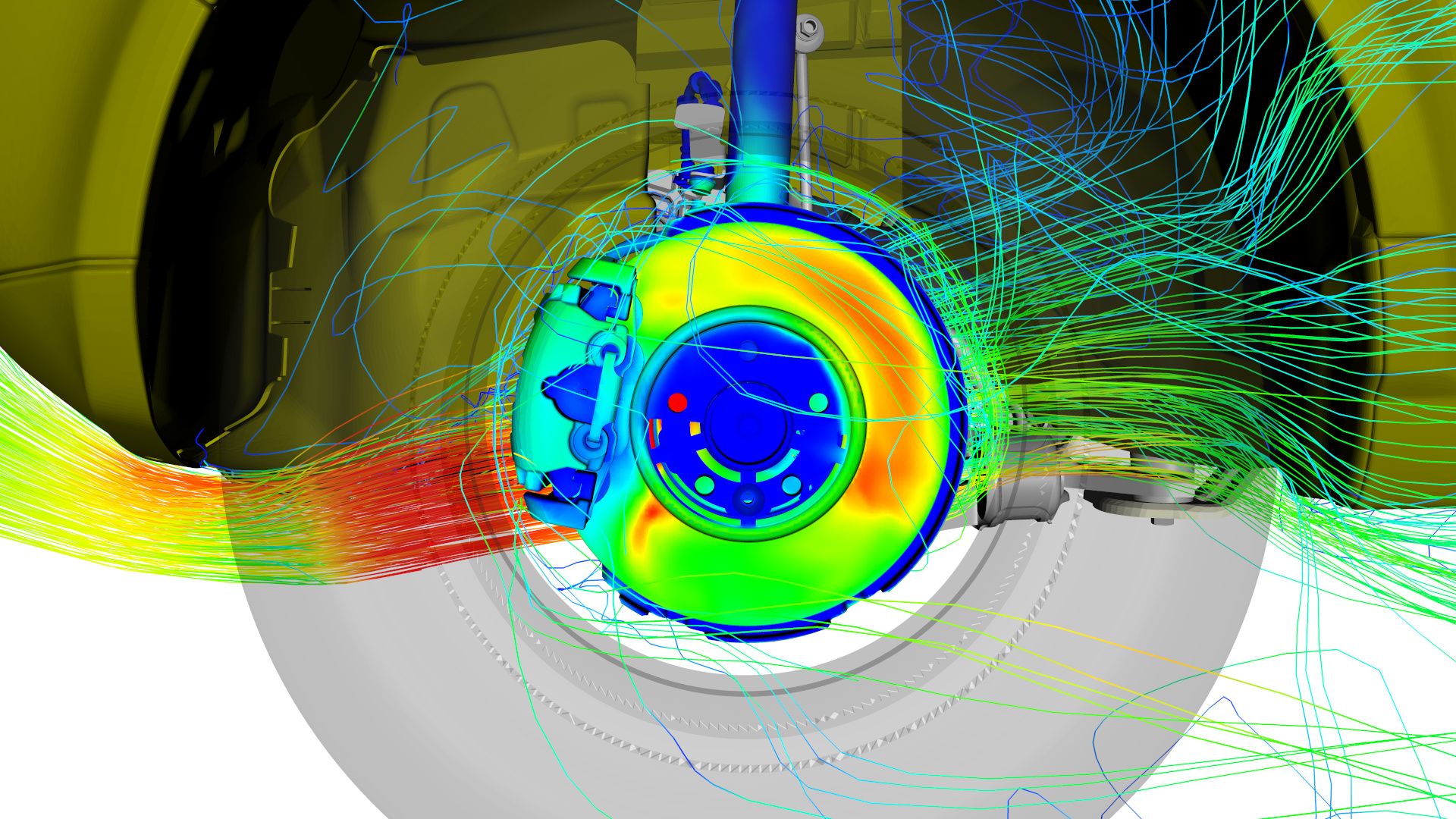

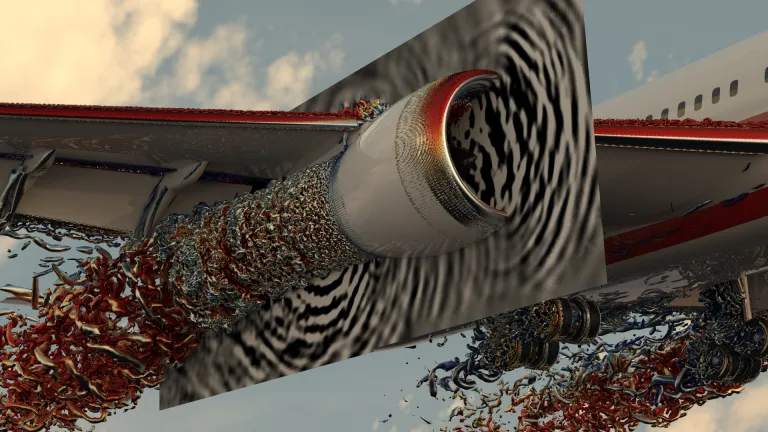

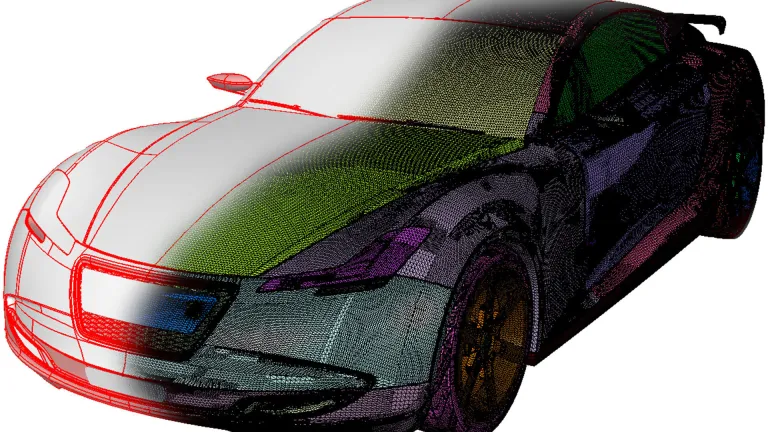

PowerTHERM® coupled with PowerFLOW provides a complete, extensively validated digital thermal management solution. Calculations in PowerTHERM predict surface temperatures and heat fluxes generated by heat radiation, conduction, and convection. The combination of PowerFLOW with PowerTHERM enables you to accurately predict temperatures and visualize the flow and temperature fields for the entire vehicle. You can then identify problem areas and provide recommendations to improve the design. Rapid turnaround time for simulation and model creation enables you to quickly make design changes to the baseline and evaluate improvements in thermal performance. PowerFLOW uses unique, inherently transient Lattice Boltzmann-based physics that enables thermal simulations to accurately predict real-world transient airflow conditions on the most complex geometry.

PowerCOOL

Using the PowerCOOL add-on to PowerFLOW, you can model heat exchangers such as automotive radiators and charge-air coolers for under-hood cooling analysis. When coupled with PowerFLOW simulations, the results enable you to predict the calculated heat exchange between the air flow and the heat exchanger. The result is provided as the temperature of the coolant at the heat exchanger inlet (top tank temperature) or the heat rejection. Other results include the distribution of air parameters like velocity, temperature, and density on the surface of the heat exchanger; and coolant temperature distribution within the heat exchanger. These results provide essential information needed to position the heat exchangers correctly and optimize the overall under-hood design of a vehicle.

- Features & Benefits

- Key Capabilities

- Application Solutions

Features & Benefits

- Faster product development. Improve designs through early-stage thermal evaluation.

- Reduce development costs. Decrease or eliminate the need for prototype testing throughout the design process.

- Improve products. Comprehensive, early-stage thermal testing results in better products with increased reliability and longevity.

- Warranty. Improved thermal evaluations catch potential warranty risks early in the process.

- Improve efficiency. Improve vehicle efficiency by maintaining optional thermal operating conditions.

- Increase customer satisfaction. Increase customer satisfaction through analysis of cabin airflow and occupant comfort.

- Improve thermal safety with PowerCOOL. Ensure that heat-generating exchangers are at safe temperatures with optimized coolant flow and pressure.

Key Capabilitites

Advanced solver for radiation, conduction & convection

- Multi-bounce radiation.

- Shell and solid conduction models.

- Convection via coupling with PowerFLOW.

- 1-d advection and fluid stream models for modelling coupled internal flows (e.g.: Exhaust system).

- Temperature-dependent properties include conduction, specific heat and emissivity.

- Handles multi-layer parts: Solid, air, vacuum or mixed.

- Efficient and robust numerical scheme with adaptive solution algorithms.

Accurate & efficient over many time scales

- Steady-state or transient

- Simulation period of a few seconds to hours

High-performance & easy-to-use

- Rapid, easy-to-use thermal model creation and case setup

- Integrated coupling with PowerFLOW fluid simulations or ability to run as a stand-alone application

- Results analyzed using PowerVIZ®, a powerful simulation results visualization & analysis environment – a single environment for analyzing flow results

- Optional parallel processing for reduced simulation time

Battery cell model

- Optional module for coupled thermal-electrical analysis of a battery cell or pack

- Supports both charging and discharging states

- Captures realistic time-varying loads and charges

Climate control analysis

- Solar loading – direct, diffuse, or reflected

- Wind loading

Human comfort model

- Optional module for advanced human thermal comfort within complex environments

- Creates a virtual test consisting of dummies with clothing layers into a virtual operational environment to compute comfort indexes

- Full radiant, convective, and conductive heat transfer

- Computes localized thermoregulatory responses such as perspiration, respiration, and blood flow changes

- Steady-state or transient localized thermal sensation and comfort analysis

Air-cooling applications

- Geometry optimization is available for under-hood radiators (I- and U-type) and charge-air coolers.

- Heat transfer between the internal and external flow is measured based on the temperature difference in inlet coolant temperature or heat rejection.

- Air flow is calculated by PowerFLOW; coolant flow is calculated by PowerCOOL. All capabilities are integrated in PowerCASE.

Using core CFD technology behind our simulation software, PowerTHERM has been validated to help solve many thermal management problems, including:

- Underbody and engine compartment thermal protection

- Brake cooling

- Key-off/soak

- Electronics and battery cooling

- HVAC system performance

- Cabin comfort

- Defrost and demist

- Heat exchanger cooling (PowerCOOL)

Application Solutions

Using core CFD technology behind our simulation software, PowerTHERM has been validated to help solve many thermal management problems, including:

- Underbody and engine compartment thermal protection.

- Brake cooling.

- Key-off/soak.

- Electronics and battery cooling.

- HVAC system performance.

- Cabin comfort.

- Defrost and demist.

- Heat exchanger cooling (PowerCOOL)

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering