PowerDELTA

Geometry Preparation for Design Simulation

Accelerates Design with Advanced Simulation Meshes

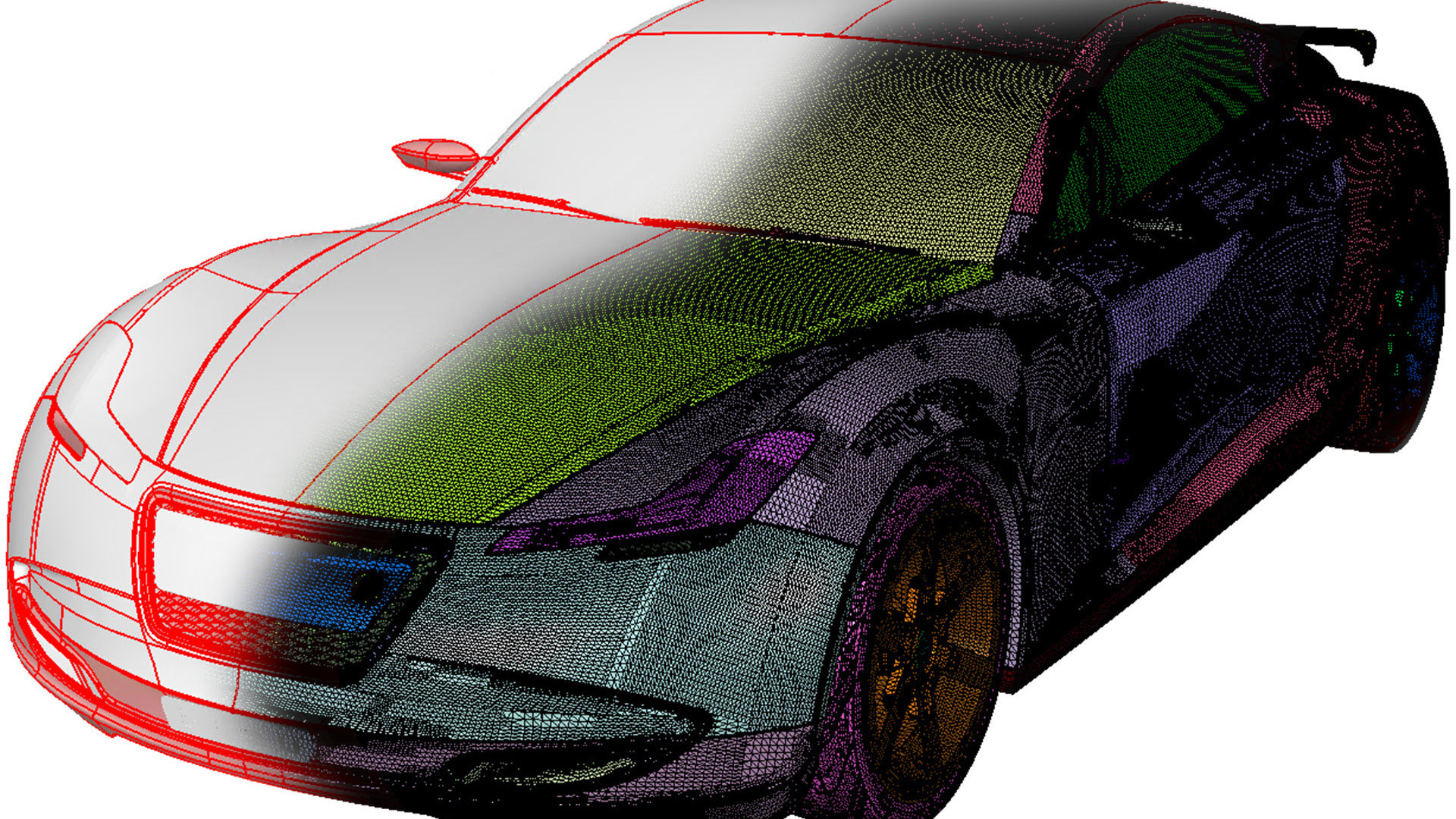

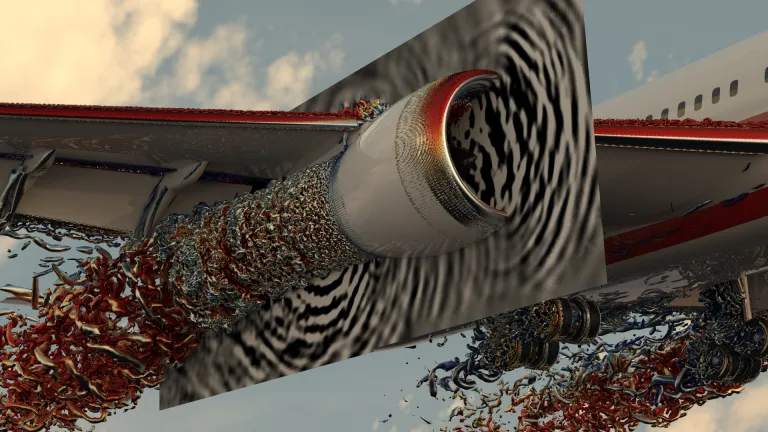

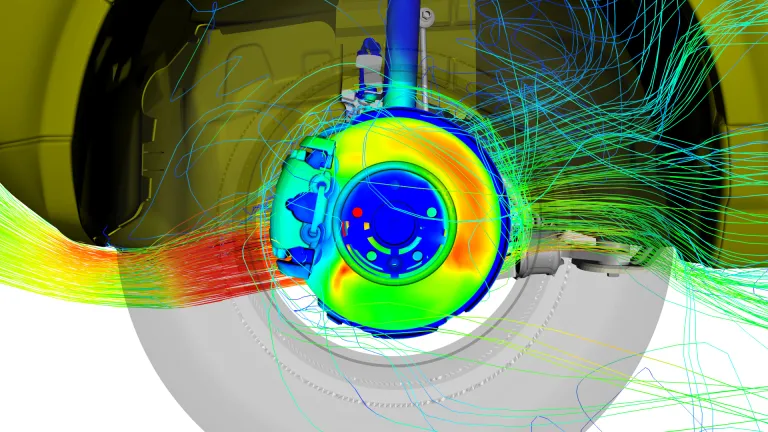

PowerDELTA is a fully featured surface mesh creation tool that prepares real-life geometries for digital simulation with PowerFLOW. Utilized early in the design process, this software can develop new meshes or detect and mend gaps in existing CAD renderings to eliminate the need for manual third-party tools. PowerDELTA offers the industry’s highest quality simulation meshes at turnaround times that are 20–75% faster than that of competitors. PowerDELTA works to connect simulation results with design direction to streamline workflows and improve product development for leading manufacturers.

- Features & Benefits

- Key Capabilities

Features & Benefits

- Geometry creation. Engineering simulations can use new and incomplete CAD geometry (such as studio surfaces and past program data).

- Simulation preparation. Engineers can identify, analyze, and correct mesh issues faster and with better usability to achieve the highest-quality PowerFLOW mesh in the fastest times in the industry.

- Concurrent design & collaboration. PowerDELTA centralizes CAD and engineering product development into one evolving model that can be used in multiple types of simulations.

-

Precise Wrap. Precise Wrap automatically fills gaps and holes that meet the specified threshold values, but leaves the input mesh outside the gap area as-is. The operation adds facets only to close the gaps, without modifying the quality of the input mesh, providing the user with a high-quality surface mesh. Precise Wrap can fill highly complex gaps and holes, such as seal gaps and door handle holes, which would require painstaking manual intervention.

-

Automation. Automation through operations template enables complex model build workflows for aerodynamics, aeroacoustics, and aero-thermal simulations using PowerFLOW and PowerTHERM.

- Geometry editing. Geometry can be prepared efficiently and accurately with new geometry editing tools, such as face extension, filleting, removing face, scaling and more.

Key Capabilitites

Early influence

- Geometry creation, mesh analysis and mesh editing capabilities in PowerDELTA enable engineers to prepare for the simulation processes.

- When utilized early in the design process, PowerDELTA can help teams reduce cycle time and save valuable resources while improving product reliability, durability and compliance.

Speed & Quality

- Only PowerDELTA can create simulation-ready meshes with industry-leading speed and quality.

- Product design and development teams receive the most accurate, real-world simulation results sooner as engineering turnaround is reduced by 20–75% and as throughput is increased by as much as 2X.

Integrated design

- Only PowerDELTA can create simulations.

- A single, evolving model managed in PowerDELTA can be used by all the simulation methodologies throughout the PowerFLOW suite.

- Integrate this intuitive morphing and optimization process across various teams and engineering disciplines in your organization for a better concurrent design process.

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering