Our solution to design sheet metal enclosures

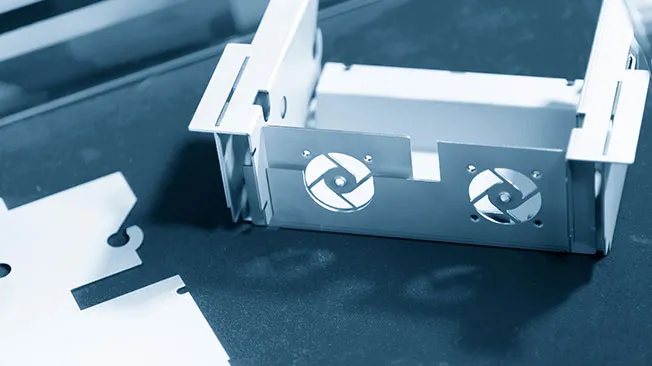

Custom sheet metal enclosures are an important feature of many products found in our homes and workplaces. In this article, we explain the importance of sheet metal enclosures and look at the specialized CAD software engineers use to design and create sheet metal enclosures.

What is the purpose of sheet metal enclosures?

The purpose of sheet metal enclosure is to protect critical parts of components from exposure. Wires, parts, and components often need to be shielded from exposure to human contact, moisture, heat, dust, contaminants, or electrical currents. However, it can also be the case that the critical components must be stopped from coming into contact with the environment or with other parts of a machine.

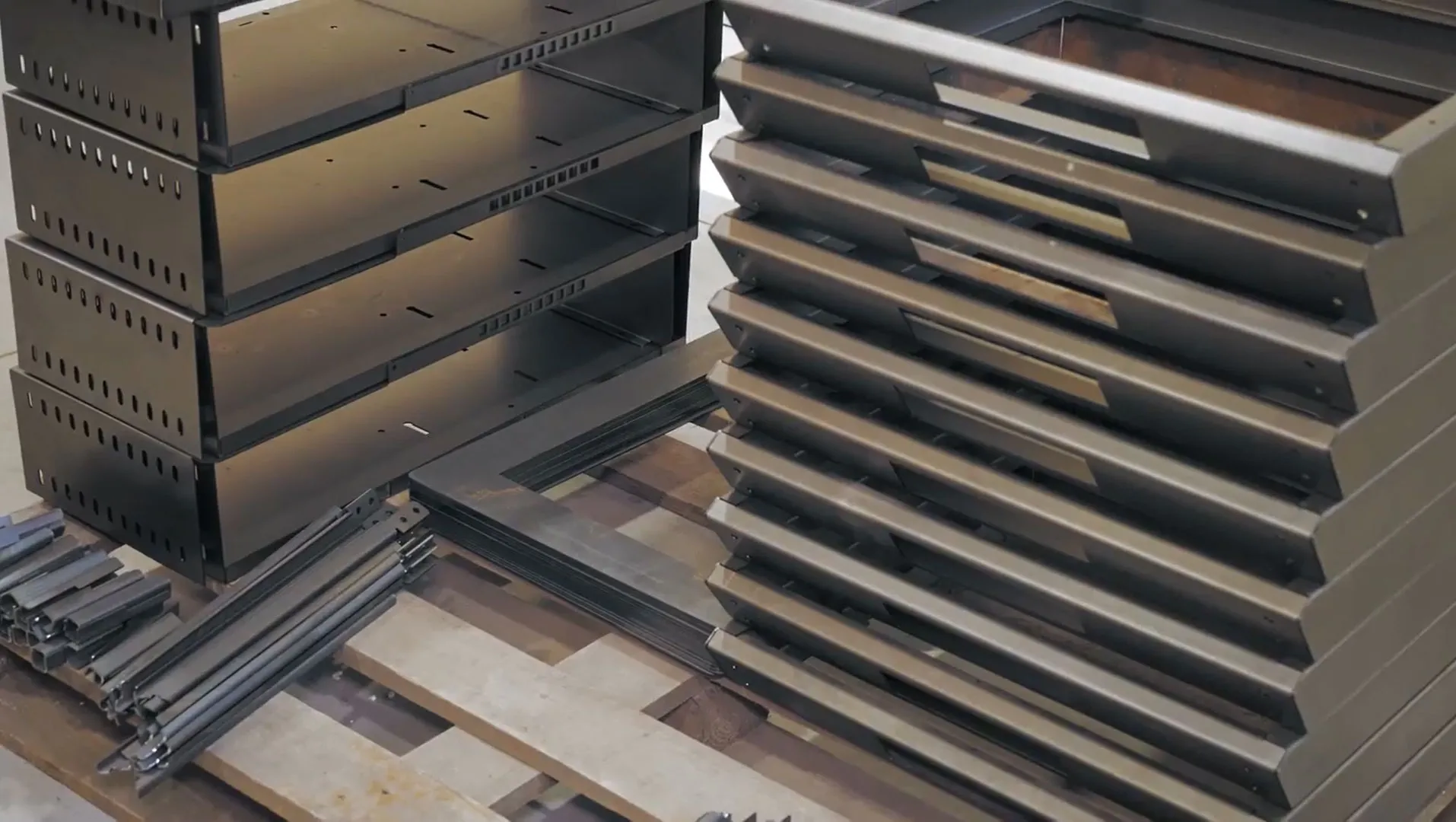

The most common way to protect these critical elements is to house them in a sheet metal enclosure, providing a secure case view of the components. Sheet metal enclosures are used because metal is durable, malleable, and can be fabricated in several different shapes. Different types of metals have a wide spectrum of properties, so designers can fabricate sheet metal enclosures for an array of purposes.

With the right design and fabrication, a sheet metal enclosure can be a highly effective solution for protecting critical components. Whether it's for an electrical system, a machine part, or any other type of equipment, a well-designed sheet metal enclosure can provide the necessary protection and durability.

Explore sheet metal enclosure design solutions from Dassault Systèmes

Professional sheet metal fabrication designers turn to Dassault Systèmes for reliable, highly effective software solutions. Specialized CAD software such as CATIA provides mechanical engineers and designers with the powerful tools they need to effectively design and manufacture sheet metal products.

SOLIDWORKS Design

From mechanical 2D or 3D design to manufacturing, accelerate your processes at an affordable price.

CATIA Mechanical Designer

Advanced mechanical design solution used for aeronautical and industrial applications. Create accurate and consistent 3D geometry suitable for large assemblies.

Why is it important ?

It’s difficult to overstate the importance of sheet metal enclosures for industrial designers. Any industry that designs products with sensitive parts or components or products that are to be used in extreme temperatures will require sheet metal enclosures for housing intricate details.

Sheet metal enclosures are used to shield sensitive components from other parts of a machine, from human contact, from temperature fluctuations, electricity, vibrations, or outside contaminants. Additionally, sheet metal enclosures are crucial for safeguarding critical parts in the event of a machine failure, ensuring their protection within specified dimensions of fabrication.

Examples of products that use sheet metal enclosures

Practically any item that is produced using metal fabrication will require a metal enclosure of some sort in stock. Precision sheet metal enclosures and small sheet metal housing can be found in everything from consumer goods to electronics to automobiles to aircraft. A desktop computer is housed in a metal enclosure and contains various parts that are housed in sheet metal enclosures.

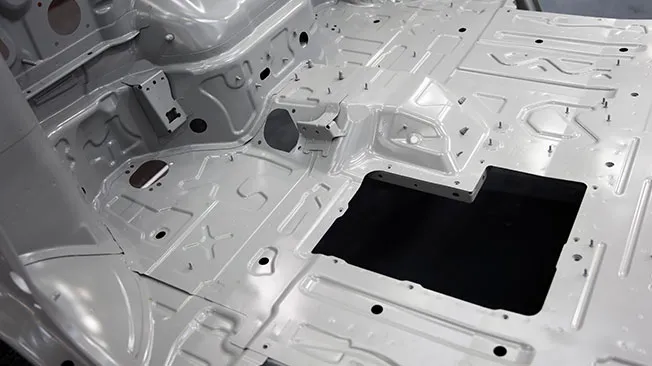

The wiring in audio mixing desks is protected from interference by sheet metal enclosures. Cars, boats, and aircraft use sheet metal enclosures to keep components separate and to protect vital electronic computer systems from fluids. A common household microwave or a refrigerator both require a sheet metal enclosure for housing their internal electronic components securely within boxes.

Browse all the Dassault Systèmes store applications

We feature in our store some of our best software to design, collaborate and innovate throughout the entire product lifecycle.

Content related to sheet metal enclosures

What materials are used for creating a piece?

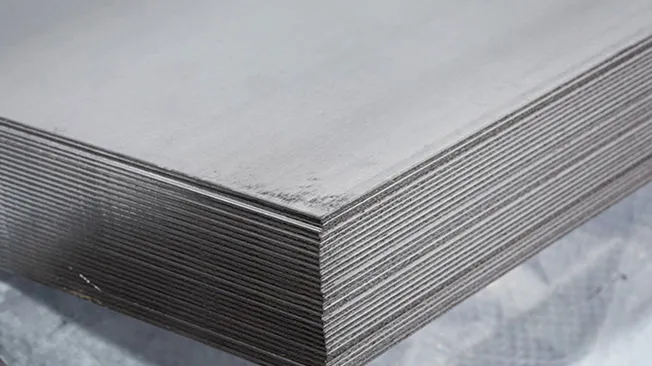

Finding the right sheet metal solution depends on the nature of the machine or product being built. Once the requirements of the particular product have been determined, a designer must then decide on what metal to use. There are five main types of metal used for sheet metal enclosures.

Aluminum

Aluminum is incredibly lightweight, malleable, and is resistant to corrosion. There are various grades of aluminum but the two most commonly used for sheet metal enclosures are 5052 and 6061. An aluminum enclosure made of 5052 can be bent into a variety of shapes without cracking. While 6061 is more prone to cracking, it can be machined more easily than 5052 aluminum.

Stainless steel

Stainless steel is highly corrosion resistant as it contains nickel and chromium. It has a high tensile strength and so is usually used for sheet metal enclosures that must withstand high impacts or large amounts of vibration.

Galvanneal

Galvanneal is a steel material that has low rates of carbon and is commonly annealed and has a zinc coating to add strength. Galvanneal stands up well to moisture and is highly corrosion resistant so it is mostly used in products that will be exposed to fluids.

CRCA

CRCA is the acronym for cold rolled close annealed steel. Although it is prone to rusting if it is not coated, the stiffness and strength of CRCA make it ideal for sheet metal enclosures that are not going to be exposed to extreme conditions.

Copper

Copper is the least used of these metals when it comes to sheet metal enclosures, but it still has specific attributes that make it a good option in certain cases. Copper has high rates of thermal conductivity and electrical conductivity which means it is often used to build sheet metal enclosures for electrical products. The malleability of copper, however, means that many manufacturers choose other metals for their sheet metal enclosures.

What are the typical shapes of sheet metal enclosures?

The other major choice a mechanical designer or mechanical engineer has to make when designing a sheet metal enclosure is what shape the enclosure will be. There are four shapes that are commonly used in sheet metal design.

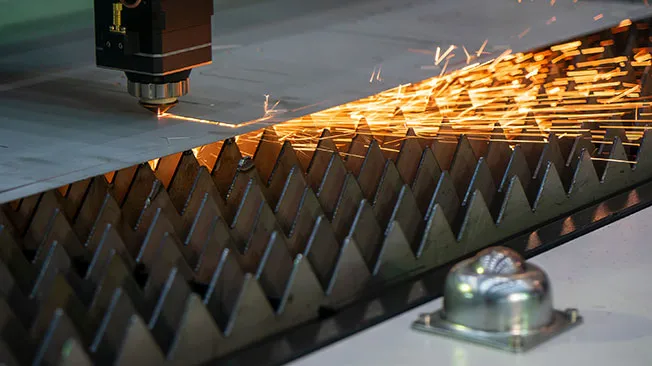

Common manufacturing processes for sheet metal enclosures

Various techniques are used to manufacture sheet metal enclosures. Sheet metal cutting is used to produce the sides and tops of a sheet metal box. Bending and forming sheet metal techniques are used to produce F-shaped, L-shaped, and U-shaped sheet metal enclosures. Stamping techniques such as deep drawn stamping and progressive die stamping are used to join sheet metal components together. Finishing processes for sheet metal enclosures include annealing, heat treatments, and hardening.

Applications of sheet metal enclosures

There are hundreds of ways in which sheet metal enclosures are used. The consumer electronics industry uses sheet metal for electrical enclosures that shield components from electricity. Industrial machinery and equipment often require sheet metal enclosures to keep components separate.

Most telecommunications and networking equipment are built with a sheet metal cabinet to keep the wiring safe. The automotive and transportation industries use sheet metal enclosures to protect computing systems, shield wiring, and stop fluid from corroding or contaminating sensitive components.

Explore Dassault Systèmes solutions

Discover the powerful browser-based modeling solutions from Dassault Systèmes. You can design whatever you wish, wherever you are with 3DEXPERIENCE.

Connecting data & people to foster innovation

The 3DEXPERIENCE platform on the cloud gives you access to a various set of applications that allow you to design, simulate, inform and collaborate on a project.

Advantages and limitations of sheet metal enclosures

Advantages of sheet metal enclosures

Sheet metal enclosures and sheet metal parts have numerous advantages over enclosures or parts made using glass, plastic, or other materials. Metal is incredibly durable and strong, so it has a longer lifespan and provides enhanced protection from environmental factors.

Sheet metal is also versatile and malleable, which makes sheet metal assembly and sheet metal manufacturing a relatively fast process when compared to other alternatives. Sheet metal is highly cost-effective and readily available from numerous suppliers.

Challenges and limitations of sheet metal enclosures

There are drawbacks to using sheet metal. Many designers and engineers have to face limited design options when designing a sheet metal component. Even when treated, sheet metal is highly susceptible to corrosion. Although it is easily malleable, sheet metal is prone to cracking and warping, which poses numerous challenges when manufacturing complex shapes.

Sheet metal enclosures - Conclusion & Perspectives

Sheet metal enclosures protect critical components and systems within products and machinery. The applications of sheet metal enclosures range from common household items such as refrigerators, desktop computers, and microwaves to automobiles, aircraft, highly complex electrical components, and medical devices and equipment.

To develop effective and reliable designs for sheet metal enclosures, mechanical engineers and mechanical designers need to know how to operate sophisticated 3D CAD software. CAD software allows designers to create digital models of their sheet metal enclosures. These models can then be tested and modified without the need to produce physical prototypes.

The right CAD solution will allow a designer to fold and unfold a sheet metal component and run environmental and kinetic simulations that will test its effectiveness. Many professional engineers and designers turn to Dassault Systèmes for sheet metal design software.

Why choose Dassault Systèmes for your sheet metal design needs?

Break away from IT restraints with the 3DEXPERIENCE Platform

The 3DEXPERIENCE Platform provides sheet metal design experts with the flexibility, power, and resources that they require to stay competitive. This unique program provides you with access to a cloud-based digital environment where you can collaborate with team members, share and store files, and use a range of top CAD software solutions from Dassault Systèmes such as CATIA Sheet Metal Designer.

You can use the 3DEXPERIENCE Platform with any device, anywhere in the world, at any time you choose.

Benefit from a team with more than 40 years of experience

Designing sheet metal enclosures requires a skilled team and sophisticated software that gives you the solutions and capabilities you need. For more than four decades Dassault Systèmes has been at the forefront of CAD software.

From the groundbreaking CATIA CAD software to the design powerhouse SOLIDWORKS and now the revolutionary 3DEXPERIENCE Platform, Dassault Systèmes has proven time and time again that we have the design solutions that professionals need.

You can discover new ways to collaborate, innovate, and create like never before with Dassault Systèmes.