fe-safe/Rubber

Durability Analysis Software for Finite Element Models

Advanced Elastomer Fatigue Analysis

Introducing the first commercially available software tool for the fatigue analysis of rubber and elastomers. Developers of rubber materials, components and systems increasingly rely on simulation as a routine means to address design issues. The need for durability simulation is growing exponentially and durability often dominates development agendas. Fatigue analysis solutions from Finite Element Analysis (FEA) have been commercially available for metallic components for many years. These solutions have played a vital role in qualifying design concepts across various industrial sectors. Finally, there is a solution available for elastomers.

fe-safe/Rubber is a:

- Unique, patented solution for the simulation of fatigue failure in elastomers.

- Purpose-developed tool for elastomers, possessing a formidable validation.

- Developed by Endurica, leaders in the development of elastomer technology.

- At a Glance

- Capabilities

- Benefits

fe-safe/Rubber at a Glance

Key Facts

- Integrated into fe-safe’s friendly user-interface to access finite element results, define duty cycles and specify materials.

- Accurate Material Models - highly nonlinear stress strain curves, Mullin's effect, strain crystallization.

- Temperature Dependence

- Time Dependence

- Contains a fatigue characterization scheme for efficiency and ease of application in fe-safe/Rubber. It uses material properties that are accessible through readily available experiments.

- Pre-populated Materials Database and add proprietary materials to your own database.

- Critical Plane analysis for multiaxial loading:

- A patented critical plane algorithm that considers the individual loading experiences on each potential failure plane of the material.

- Considers the effects of finite straining on the motions of each potential failure plane.

- Estimates the energy release rate of a hypothetical defect on each plane as a function of time.

- Considers the possibility of crack closure for each plane at each instance of time.

- Identifies the critical plane as the plane that maximizes accumulated damage.

- Rainflow counting on a per-plane basis for variable amplitude loading.

- fe-safe/Rubber damage accumulation calculations consider the contribution from each peak and valley.

fe-safe/Rubber is an add-on module to fe-safe.

fe-safe/Rubber Capabilities

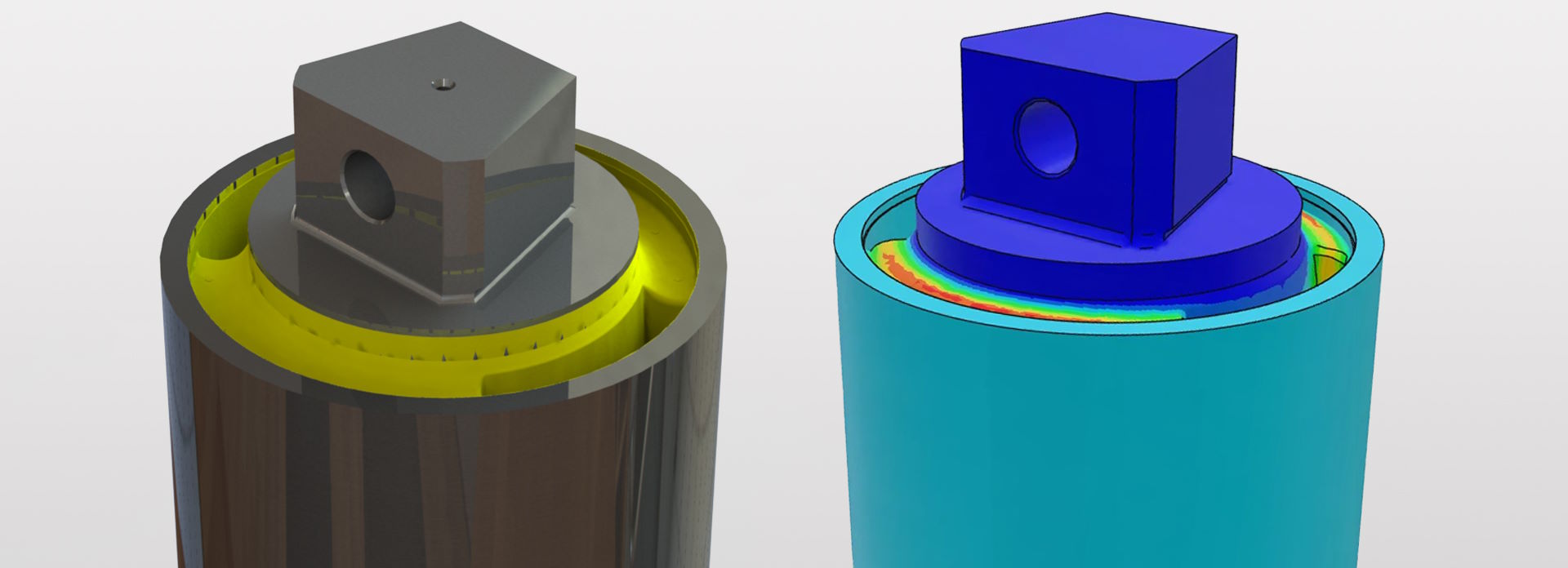

fe-safe/Rubber estimates the fatigue life of a rubber component. Based on the mechanical duty cycle computed in the finite element analysis and the material properties of the rubber, it determines the necessary number of duty cycle repeats. This calculation takes place for each location on the component to predict the formation of a small crack. It highlights fatigue lives as color contours on the FE model, showing the critical locations where cracks could start to develop.

fe-safe/Rubber features a patented critical plane algorithm developed specifically for finite straining. This algorithm accurately accounts for the effects of crack closure and multiaxial loading. It also features a Rainflow counting procedure for identifying and accumulating the damaging effects of each event in the duty cycle.

fe-safe/Rubber provides a selection of nonlinear material models that enable accurate representation of the behavior of the rubber component, and a database of ready-to-use properties for various popular elastomer types.

fe-safe/Rubber analyzes the fatigue performance of elastomers under real-world service conditions. Because of their macromolecular structure, elastomers exhibit unique behavior and require specialized analysis methods:

| Finite Strains | Ozone Attack |

| Nonlinear Elasticity | Mullins Effect |

| Strain Crystallization | Crack Closure |

| Time Dependence | Fatigue Threshold |

| Temperature Dependence | Microstructural Crack Precursor Size |

fe-safe/Rubber Benefits

fe-safe/Rubber is a purpose-developed tool for elastomers, possessing a formidable validation.

- Increase confidence at the inception of the design cycle.

- Save the costs of build and break experiments for well-qualified designs.

- Improve your design process with research-validated software.

- Understand the failure process from the perspective of the critical features and their localized service experiences of your component.

- Make design decisions that accurately account for material behavior and service environment.

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering