Service Engineering

Unlock the Potential of Service Operations

Define Service BOM & Processes in a Single Platform

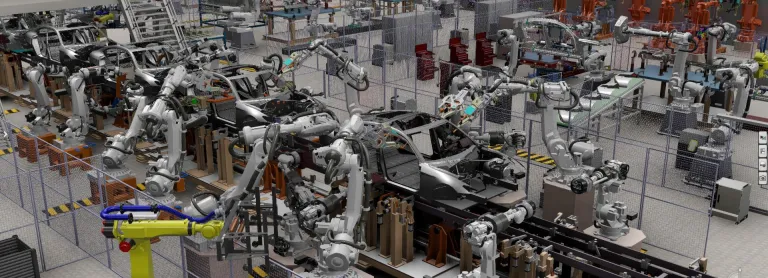

DELMIA Service Engineering extends digital continuity from engineering design to support and services. It enables users to fully define and service BOM with spare part policy definition, process definition and resources allocation in a single location. With a myriad of logistics and unplanned events on the shop floor every day, precise planning can be challenging, and errors can drive up costs. Now users can plan and validate every aspect—from the entire field and shop layout to workflows to maintenance schedules and design specifications—in a virtual environment before deploying physical resources.

Using engineering data, engineers can define the Service BOM, maintenance task activities and related service instructions. They can validate the feasibility of maintenance task activities by reviewing accessibility for tools and workers ensuring all configurations and changes are controlled on a single data model. This is done by applying product design, Service BOM, tooling, and materials knowledge in a methodologically structured Virtual Twin in Operations. Users can also test and optimize service methods and equipment virtually. They can identify any process risks earlier, create a safer environment for workers and obtain an accurate forecast of the investment costs and maintenance & repair space needed.

DELMIA Service Engineering software products are packaged as Roles to get you up to speed faster and work more efficiently with all needed applications available at your fingertips. Select a package that corresponds to your role in an organization.

When it comes to configuration control and consolidation management, a common platform is essential because it provides a holistic view of the facility.

Start Your Journey

The world of manufacturing & operations is changing. Discover how to stay a step ahead with DELMIA.

Join the conversation in the DELMIA Global Operations User Community!

FAQs

Service engineering is an industrial core process used to define:

- How a product has to be maintained with their maintenance tasks (such as aircraft, machines, cars, boats, etc.)

- Spare parts policy

Service engineering process involves four key steps:

- Maintenance requirements and Design Engineering analysis to prepare Service Bill of Material definition. What are the product to be maintained with their requirements?

- Service Bill of Material phase with spare part policy definition based on reliability information and maintenance level, in another word “Which spare part can be procurable by a maintenance operator?

- Service Process phase involves maintenance task definition with overall resources. Verify & validate mountability with 3D feasibility study. Time analysis in one click to view estimated time for overall tasks. What are the maintenance task definition to be planned and executed on the field?

- Finally, develop collaboratively and continuously improve maintenance concept from field data feedback. What are product in-service data feedback from the field?

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering