Augmented Reality in Manufacturing

Optimize assembly and inspection operations in manufacturing with augmented reality

What is Augmented Reality in Manufacturing?

Augmented Reality (AR) software is used in manufacturing to transform traditional manufacturing processes by providing real-time, contextual digital information directly from the 3D digital mock-up. With AR technology, virtual information is brought into the real world for improved production, assembly, quality and inspection where operators can better understand their environment. Bringing sense computing and AI-driven capabilities directly on the shopfloor, augmented reality in manufacturing transforms how workers perceive and interact within their environment by guiding users through tasks with precision and eliminating ambiguity that results in errors.

Physical Manufacturing Processes + Augmented Reality

Bridging the gap between the virtual and the real worlds with AR and AI, providing real-time guidance for tasks in manufacturing, improving productivity, safety and comfort.

Revolutionizing Manufacturing with Augmented Reality

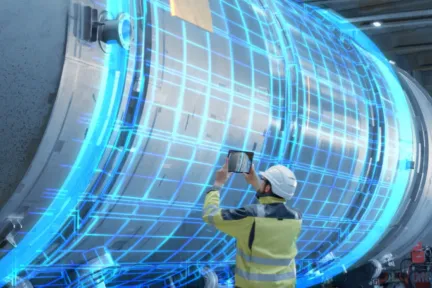

In today's fast-paced industrial landscape, Augmented Reality (AR) is revolutionizing various sectors by enhancing efficiency, accuracy and overall productivity. AR overlays digital information onto the physical world, providing real-time assistance and insights to field operators, engineers and quality control specialists. AR work instructions efficiently guide operators through assembly and inspection tasks, improving operations quality, reducing cycle times and increasing workforce comfort.

This advanced technology is bridging the gap between the virtual and real worlds, making it an indispensable tool for modern enterprises and across various industries from aerospace to transportation or industrial equipment.

Key Applications of Augmented Reality in Manufacturing

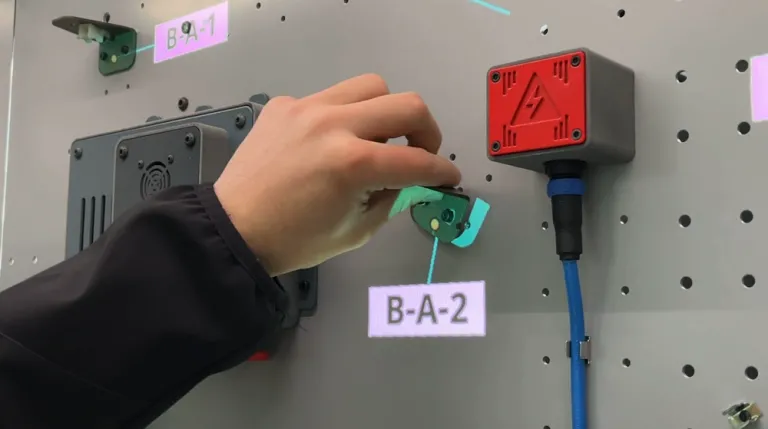

Assembly Guidance

Visual step-by-step instructions projected onto parts reduce errors and increase speed.

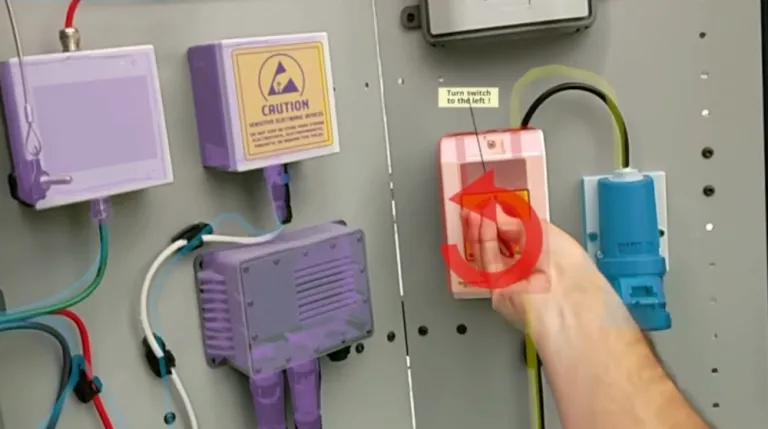

Inspection Assistance

Real-time comparisons with digital models highlight issues like misalignment or missing components.

Maintenance Support

Technicians view live diagnostic data and repair guides overlaid on equipment.

Supplier Goods Validation

AR validates the positioning conformity of tools, and jigs or even assembly elements before use on the production line.

Key Benefits of AR in Manufacturing

Enhance Accuracy

Get real-time, visual instructions directly in the operator’s field of view, reducing errors in complex tasks such as assembly and inspection. This ensures higher precision and consistent quality across operations.

Increase Productivity

By overlaying step-by-step guidance and real-time data, AR streamlines workflows, shortens cycle times, and minimizes downtime, enabling teams to complete tasks more efficiently.

Improve Workforce Training

Receive clear and precise step-by-step instructions, helping employees quickly gain the skills needed for complex manufacturing processes. This accelerates onboarding and reduces training costs.

Improve Quality Control

Using AR for inspection tasks allows operators to detect defects early by visualizing potential issues in real-time, ensuring products meet stringent quality standards.

Strengthen Safety

Minimize workplace hazards by providing clear visual instructions and alerts, ensuring operators can perform their tasks safely and confidently.

Streamline Equipment Maintenance

Get assistance with equipment maintenance by overlaying diagnostic information and repair instructions, helping technicians address issues faster and reduce downtime.

Which Industries are Getting Value from AR in Manufacturing?

Aerospace & Defense

In the aerospace and defense sector, AR assists in the assembly of complex equipment such as aircraft engines or aerostructures. By projecting digital assembly instructions directly onto the components, AR reduces errors and ensures that each step is performed correctly the first time. Quality control processes and Maintenance, Repair and Overhaul (MRO) operations are also enhanced through AR, allowing inspectors to quickly identify and rectify non-conformities using smart glasses or tablets.

Transportation & Mobility

The light and heavy vehicle industry leverages AR for a variety of applications, including inspection of jigs and fixtures, assembly of harnesses, or quality control. AR technology guides operators through intricate assembly tasks, such as the installation of brackets, screws, and other components on car bodies and truck or train frames. It also aids in the inspection of welds and bolts, ensuring that vehicles meet stringent safety standards.

Industrial Equipment

In the industrial equipment sector, AR transforms manufacturing and maintenance processes by providing real-time guidance and digital documentation. Operators can access step-by-step augmented reality work instructions overlaid on the equipment, which simplifies complex tasks and accelerates skill development.AR also plays a crucial role in inspection, helping detect defects early and maintain high-quality standards.

Other Industries

From ship building to infrastructure equipment or construction material, there are many other industries that are leveraging augmented reality for their processes to improve efficiency of manufacturing operations and reach operational excellence.

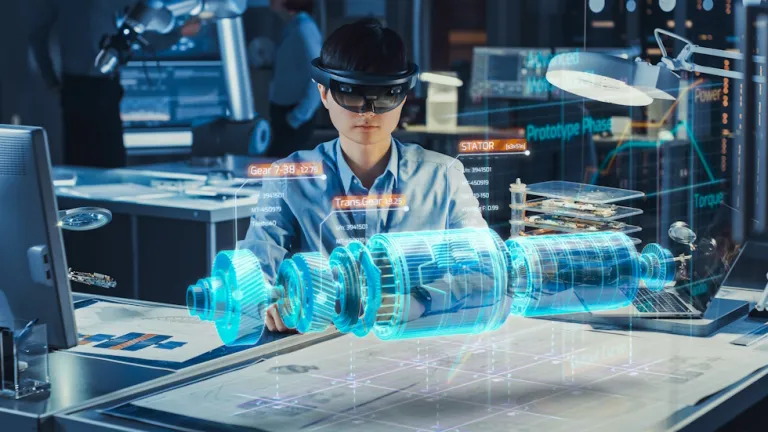

Augmented Reality & Virtual Twin in Manufacturing

In advanced manufacturing environments, AR combined with virtual twin technology is enabling operators to interact with real-time production data directly on the shop floor. For example, when an operator performs an inspection task, the virtual twin can flag a deviation based on sensor feedback or simulation data, then AR immediately overlays corrective instructions on the physical asset.

During assembly, the virtual twin simulates process paths and tolerances and AR projects those exact configurations on the product, guiding workers to act precisely without pausing for manuals or digital screens. This synergy ensures that what was validated in the virtual model is executed flawlessly in reality, accelerating iteration cycles, supporting right-first-time execution and making continuous optimization part of daily operations.

Our Customer Stories with AR in Action

Latecoere

Boosting Quality Inspection

Latecoere leverages DELMIA Augmented Experience to enhance aerostructures' quality inspection and drive zero-defect manufacturing.

With DELMIA Augmented Experience we are reducing inspection time by 20% to 30% and it makes our inspection methods more reliable.

Start Your Journey

The world of Augmented Reality is changing. Discover how to stay a step ahead with DELMIA Augmented Reality in Manufacturing.

Augmented Reality in Manufacturing FAQs

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering