Machining

Boost precision, reduce programming time, and streamline workflows with DELMIA’s advanced CAM automation for efficient manufacturing.

What is the Value of DELMIA Machining Software?

DELMIA Machining is an advanced CAM (Computer-Aided Manufacturing) software designed to optimize CNC programming, simulation, and machining operations. It provides a fully integrated 3D modeling and simulation environment, allowing manufacturers to maximize machine performance and improve efficiency. By enabling seamless digital continuity, DELMIA Machining helps industries reduce production time, minimize errors, and enhance precision in manufacturing processes.

Optimize Machining Programming and Operations

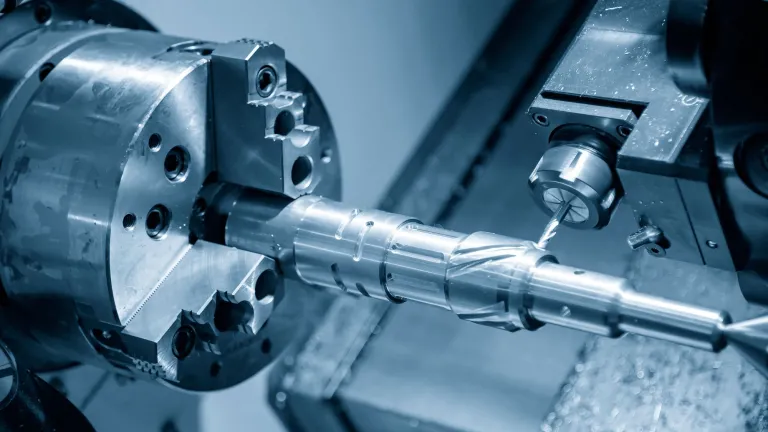

Our CAM software supports a wide range of machining operations, from milling and turning to multi-axis machining, allowing you to tackle any project with confidence. Users can simulate the real behavior of complex machine tools, and quickly generate G-code for CNC machines. The solution provides ease of use by implementing a standardized user interface for programming machines of all types, making it easier to incorporate and deploy new machine tools. This approach delivers a reduction of lead-time from design to production and reduces programming hours by up to 80% for modified versions of existing parts and products. DELMIA Machining lays the foundation for continuous improvement by capturing and reusing knowledge through templates, tool setups and cell designs.

Key Features of DELMIA Machining

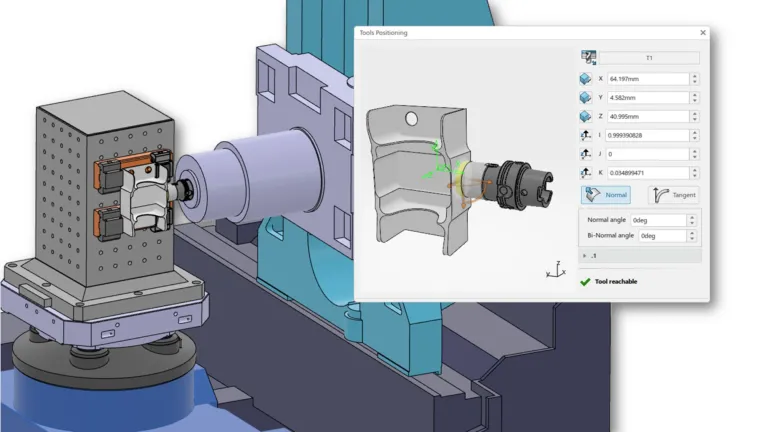

Integrated 3D Simulation

DELMIA Machining provides a realistic 3D simulation of the entire machining process, from tool assembly to tool path generation. This allows operators to visualize, validate, and optimize machine movements before production, reducing errors and ensuring smooth operations.

Advanced CNC Programming

With intelligent programming automation, DELMIA significantly reduces the time needed to create and modify CNC programs. Using predefined templates and reusable tool paths, manufacturers can cut programming time by up to 80% while maintaining high precision.

Complex Machining Support

The software supports a wide range of machining operations, including milling, turning, and multi-axis machining. This versatility allows manufacturers to tackle complex geometries and high-precision parts, improving production flexibility.

Seamless CAD & CAM Integration

By combining CAD (Computer Aided Design) and CAM within a single environment, DELMIA ensures smoother transitions from design to manufacturing. The software automatically detects geometrical modifications, reducing the impact of design changes by up to 90%.

Standardized User Interface

DELMIA Machining offers a unified programming interface for all machine types, making it easier to adopt new CNC machines. This standardized approach enhances usability, reduces training time, and improves operational efficiency.

Benefits of CAM Software & DELMIA Machining

Reduced Lead Time

DELMIA’s automated programming tools streamline CNC programming, reducing lead time and speeding up production. With knowledge-based automation, manufacturers experience up to 80% faster programming cycles.

Improved Quality

Integrated machine simulations allow for early detection of potential errors, ensuring optimal tool paths and machining strategies. This results in a 30% increase in part quality, reducing defects and material waste.

Minimized Design Changes

With automatic geometry modification detection, DELMIA minimizes the disruption caused by design modifications. This feature helps reduce the impact of design changes by up to 90%, ensuring seamless adaptability in production workflows.

Streamlining Your Workflow with DELMIA Machining

- Advanced CAM for every CNC machine and process

- Simulation in a 3D virtual twin environment

- Programming automation and knowledge management

Advanced CAM for Every CNC Machine and Process

DELMIA Machining supports all machining processes covering full spectrum of machine types.

- Milling: 2- to 5- axis , milling with robots, drilling & riveting, adaptive concentric milling

- Mill-Turn with support for up to 5-axis simultaneous milling

- Production turning, multi-spindles, multi-turrets programming (SWISS machines included)

- Synchronized machining: balance turning or follow turning B-Axis management

- Support tools such as multi-cutter, Y-axis parting tool and d’ Andrea head Wire EDM, laser cutting and water jet cutting

- Direct connection to cutting tool libraries Feature recognition automatically identifying machinable features

Simulation in a Virtual Twin Environment

Real-time toolpath verification accurately calculates the toolpath ensuring it performs as designed. All other elements of the work cell can be simulated including

- Part loading

- Tooling clamping

- Cutting tool activation

- Start of machine

This simulation helps our users to reduce the machine setup time by 50-60% on average. It drastically reduces the number of iterations during the test run. In addition, intermediate stock function helps to see how the subsequent machining operations will impact machining.

Programming Automation and Knowledge Management

Leverage management knowledge management to automate CAM to achieve:

- Auto-generation of NC code, reducing programming time through automation and tool path re–reuse

- Ability to define program templates and to reuse NC programs, definitions of cutting tools and machines

- Capability to store your company’s know how to quickly create new programs based on proven previously used sequences of operations

- Collaborative environment to access to NC programming, data management and cutting tools in a single environment across programming offices and multiple locations

- Automatic management of associativity between processes, products, NC programs, machines, accessories, tools and tool assemblies in a single unified database

Open and Flexible Solutions with DELMIA Machining

- Integrated CAD/CAM Environment

- Available On The Cloud

- Post Processor

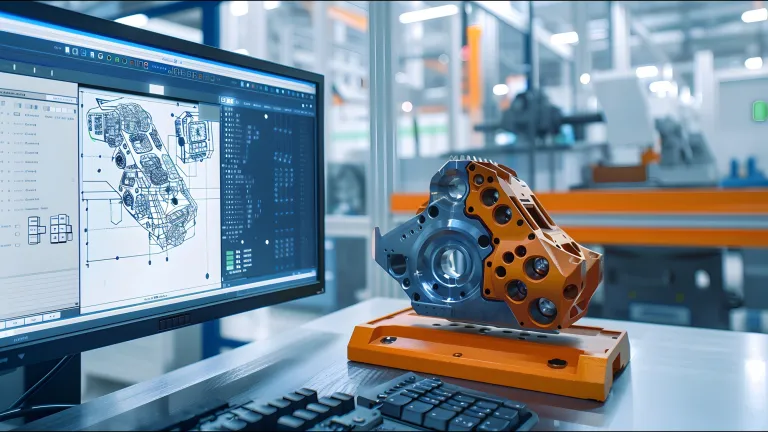

Integrated CAD/CAM Environment

DELMIA Supports the CAD/CAM Workflow by optimizing critical stages like design, post-processing, and simulation, emphasizing automation and efficiency. This leads to:

- Better collaboration between Designers & NC Programmers to improve engineering efficiency with automatic operations update on geometrical design modification detection

- Machining operations are calculated on exact geometry generating faster and higher quality toolpaths on CAD model geometry and not on meshed data

- No time is wasted on file transfers as all activities share the same data.

- Single platform for all machining data enabling sharing of programs, cutting tool information and programming best practices, across many programming offices

- Improved live collaboration across departments and with suppliers avoiding e-mail disconnected communication thanks to ability to share design and project data with annotations with every stakeholders

Available on the Cloud

With DELMIA Machi the cloud, gain access to data anytime and anywhere. This also includes:

- Automatic updates and upgrades

- Secure, protecting data from unauthorized access and loss

- Lower IT infrastructure and maintenance costs

- Improved collaboration across departments

- Enhanced synchronization between NC programming and design; and between NC Programming and the shopfloor

- Improved collaboration and best practices sharing across locations and with customers

Post Processor

After the NC program creation, it is key that the programs are translated into ISO code which can be read by a NC controller. Multiple options are available in DELMIA Machining to realize the translation. In addition:

- Use the embedded post processor generator On Cloud to generate ISO codes for machines having not more than 3+2 axis simultaneous movements

- Implement standard post-processors delivered from our partner inside the application for On Premise and On Cloud solutions or contact one of our partner to customize a dedicated post-processor according to your exact specifications.

How DELMIA Machining Leverages AI

The AI in DELMIA Machining is neither a "black box" nor directive. It functions like a GPS, but a GPS specifically for machining, offering different options. Just as a GPS, in complex situations such as a congested or blocked road, can suggest surprising alternative routes, even if you are familiar with the area. You then discover interesting detours. This is exactly what the AI in DELMIA Machining offers — alternatives you might not have considered, thus opening up new machining possibilities.

Machining Product Comparison

| Category | Users | Roles | Key Features |

| Define shop floor resources | NC Equipment Engineer Cutting Tool Expert | Shop Floor Equipment Engineer, Machine & Tooling Designer Cutting Tool Technologist | Create kinematics for NC machines, robots, accessories, or existing designs Design and add kinematics for NC machines, robots, accessories from scratch Create and import NC cutting tools from tool manufacturers including accessories without kinematics |

| Program NC Machines | NC Programmer | NC Shopfloor Programmer NC Prismatic Machine Programmer NC Prismatic & Mill-turn Machine Programmer NC Mold & Die Programmer NC Milling Machine Programmer NC Mill-turn Machine Programmer | Basic solutions with a few 2.5 X or 3X functionalities including wire EDM and laser/water jet cutting Complete solution for 2.5X including adaptive concentric milling and NSR content Complete solution for 2.5X and turning including adaptive concentric milling and NPM content Complete solution for 2.5X and 3X including adaptive concentric milling and 3-5X converter Full milling solution for 2.5X, 3X and 5X including machining with robots Full milling and turning solutions for 2.5X, 3X and 5X including machining with robots

|

| Define Knowledge | NC Knowledge Expert | NC Knowledge Manager | Define the NC know-how of your company |

| Simulate NC Machines | NC Operator NC Simulation Expert | NC Shopfloor Reviewer NC Simulation Engineer NC Code Simulation Specialist | Review and simulate NC programs Simulate NC code offline Export external NC code simulation |

DELMIA Machining & CAM Software Solutions

DELMIA Machining software products are packaged as Roles to get you up to speed faster and work more efficiently with all needed applications available at your fingertips. Select a package that corresponds to your role in an organization.

Our customers come to us with major challenges relating to machine processing, time constraints and increasingly stringent specifications.

Real Customer Success in CAM & Machining

Discover how industry leaders like Sandvik Coromant, Carbomill, and Bilfit AG use DELMIA Machining & CAM solutions to optimize precision and complex manufacturing challenges:

Start Your Journey

The world of manufacturing & operations is changing. Discover how to stay a step ahead with DELMIA.

FAQ about Machining Software

Computer-Aided Manufacturing (CAM) software automates CNC machining processes by generating toolpaths and instructions from 3D CAD models. It bridges design and production, ensuring precise, efficient, and repeatable manufacturing for industries like aerospace, automotive, and industrial machinery.

A CAM application analyzes the geometry of a digital model, selects the best cutting tools and toolpaths, and generates G-code instructions to control CNC machines. Advanced CAM solutions, like DELMIA Machining, integrate simulation, automation, and AI-driven optimization, reducing errors, setup time, and material waste.

| Feature | CAD (Computer-Aided Design) | CAM (Computer-Aided Manufacturing) |

| Definition | Used for designing and creating 2D and 3D models of products before manufacturing. | Used for controlling and automating manufacturing machines based on CAD designs. |

| Primary Function | Focuses on product design, drafting, and visualization. | Focuses on generating toolpaths, programming CNC machines, and optimizing production. |

| Key Users | Engineers, architects, designers. | Manufacturing engineers, machinists, CNC operators. |

| Output | Technical drawings, 3D models, blueprints. | G-code, CNC programs, machining instructions. |

| Integration with Manufacturing | Used in the initial design phase before manufacturing begins. | Takes CAD designs and translates them into machine instructions for production. |

There are several types of CAM software, each designed for specific machining processes:

- CAD/CAM Software – Integrates design and machining workflows for seamless production.

- CAM Simulation Software – Predicts machining outcomes to prevent errors before production.

- CAM Optimization Software – Enhances toolpaths to improve efficiency and reduce machining time.

- CAM Nesting Software – Maximizes material usage in sheet metal cutting and laser/waterjet applications.

- CAM Milling & Turning Software – Tailored for milling, turning, and multi-axis machining operations.

Simulation tools in CAM software reduce setup time by 50-60% by allowing engineers to virtually test machining processes before running them on real machines. This prevents tool collisions, improves tool life, and minimizes material waste, ensuring higher accuracy and faster production cycles.

Modern CAM solutions integrate with Industry 4.0 technologies, such as IoT, AI, and cloud computing, to enhance real-time monitoring, predictive maintenance, and data-driven decision-making. By connecting CAM software with smart factories, manufacturers gain better process control, automation, and efficiency.

The CAM industry is evolving with:

- AI-driven automation – CAM software now optimizes toolpaths and machining strategies dynamically.

- Digital Twin Technology – Virtual models simulate entire manufacturing processes for optimization.

- Additive & Hybrid Manufacturing – CAM software now integrates 3D printing and traditional machining.

- Cloud-based CAM Applications – Allows remote access, team collaboration, and faster deployment.

Machinists use specialized CAM software to program CNC machines, including:

- CAD/CAM software for seamless design-to-manufacturing workflows.

- CAM simulation tools to predict errors and optimize cutting strategies.

- Toolpath optimization software to enhance cutting efficiency and reduce wear.

- Industry-specific CAM applications like DELMIA Machining for multi-axis machining, automation, and real-time collaboration.

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering