SIMULIA Transportation & Mobility Solutions

Designing the future of transportation. From cars to trucks to trains to bikes – simulation helps engineers make them faster, safer, greener and more reliable.

Simulation Accelerates and Derisks Vehicle Development

We are in the middle of a mobility transformation, driven by trends such as sustainability and urbanization. The automotive industry needs to radically reinvent its products to meet new emissions standards and to bring new technologies such as electric drive and hydrogen engines to market. Meanwhile, rail is seeing a construction boom for both high-speed lines and mass transit, and the challenges of urban personal mobility are being met by innovative technologies such as e- bikes and e-scooters.

To be competitive, manufacturers, suppliers and construction companies need to stay ahead of this rapid change. However, developing a new vehicle – especially a clean-sheet design – is a long and expensive process that carries considerable risk. In addition, new standards such as Worldwide Harmonised Light Vehicle Test Procedure (WLTP) increase the amount of testing needed drastically. Simulation provides a solution to these challenges, speeding up the development cycle while decreasing the requirements of testing.

With simulation, designers can optimize the performance of an individual component or the entire system on a virtual twin of the real product. Simulation can be used at any stage of development, from the initial concept to the final design to analyze factors including structural integrity, aerodynamics, noise, vibration, comfort, handling and many others. Potential issues can be identified and resolved before building physical prototypes, reducing the risk of costly late-stage redesigns.

The SIMULIA portfolio of simulation tools offers designers and engineers a comprehensive solution for the analysis and optimization of components, vehicles and transportation infrastructure. These integrate with industry-standard computer aided design (CAD) tools and with other Dassault Systemes tools on the 3DEXPERIENCE platform.

Key Benefits of Transportation and Mobility Solutions

Test Virtually

Replace physical tests with virtual wind tunnels and driving simulators

Minimize Risk

Discover issues early in development and fix them sooner

Optimize Performance

Find the best trade-offs for power, handling and passenger comfort

Increase Sustainability

Improve fuel efficiency or develop new EV concepts

Cut Development Costs

Stay on budget by reducing design iterations and physical prototypes

Reduce Time-to-Market

Shorten development of new concepts and gain a competitive edge

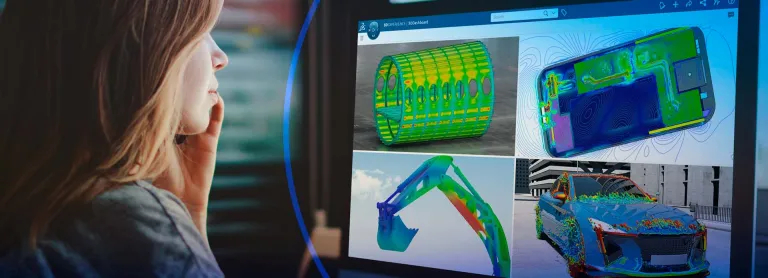

Unified Modeling and Simulation - MODSIM

With unified modeling and simulation (MODSIM), the performance of the vehicle, or any part of the vehicle, can be analyzed at any point in the development cycle. This even applies to the initial concept stage – long before building a prototype. This accelerates the development process and also reduces the risk of problems emerging during later stages of development.

The simulation models are derived directly from the CAD geometry without the need for exporting or importing into other tools. This means that updates to the design can be automatically propagated to all users, reducing the administrative workload of version management and ensuring that everyone is working with a single source of truth.

Optimal Trade-Offs with Multiphysics Simulation

Many factors go into determining the success of a design. To develop a competitive vehicle, engineers need to control safety, aerodynamic forces, engine temperature, noise, vibration, ride comfort, handling, cabin comfort and data connectivity among many other factors. These are multiphysics phenomena combining many different disciplines, including structures, fluids, electromagnetics, vibro-acoustics and multibody dynamics.

SIMULIA offers a full portfolio of simulation tools covering these disciplines. These can be combined to take into account the interaction between different physical phenomena, such as the heating caused by electric losses in electronics and the cooling effect of airflow through and around the component.

Experience it like the End User

The ride experience is what makes a car more than just a means of transportation. From the suspension to the wind noise, and from the air conditioning to the seat comfort, every detail must be right to maximize the driver and passenger experience. Simulation can model the behavior of the vehicle under realistic conditions anywhere in the world without having to leave the office.

Virtual twin experiences replicate the driver experience for the engineer. Designers can see, hear and even feel what passengers experience as the car drives down the road. Real-time motion simulation provides Hardware-in-the-Loop (HiL) and Man-in-the-Loop (MiL) capabilities – realistic physics simulation can interface to driving simulator, providing immediate physical feedback to the virtual test driver, letting them feel every bump in the road.

Design for Sustainability

The transportation industry is in transformation. Electric vehicles are hitting the roads in ever greater numbers, led by innovation in battery, motor and autonomous/driver assistance systems (ADAS) technology. Meanwhile, the fields of public transit and active transportation have seen significant interest and innovation in recent years. Simulation is helping engineers to develop new vehicles and transportation solutions for tomorrow, faster and with less development risk.

No matter the transportation mode, energy efficiency is crucial. The Worldwide Harmonized Light Vehicle Test Procedure (WLTP) requires fuel efficiency to be reported for every variant of a vehicle, which is expensive and time consuming without simulation. From minimizing aerodynamic drag and tire resistance to finding the most efficient operating regime for motors, simulation powers the optimizations that improve the fuel consumption and range of vehicles.

SIMULIA Customers in Transportation and Mobility

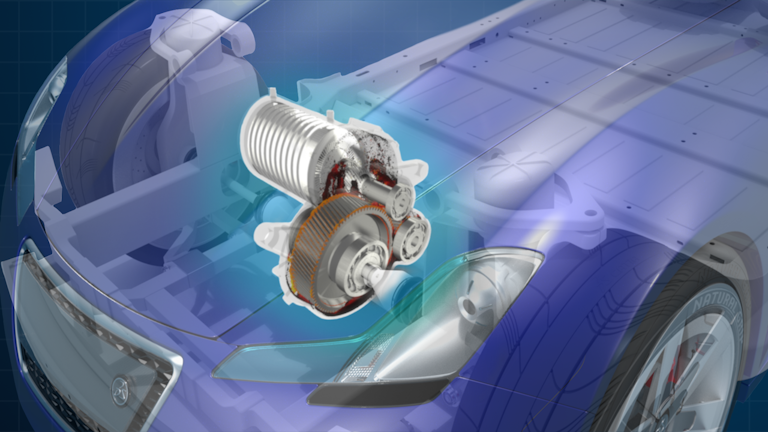

Electric Drive Engineering

Developing the drive system for an electric or hybrid vehicle is very different from internal combustion engine design. Motors, cabling, cooling, power electronics and the battery all need to be designed to ensure safety, reliability and efficiency. Optimization powered by simulation helps engineers improve electric performance and range, and find the best trade-off between competing variables.

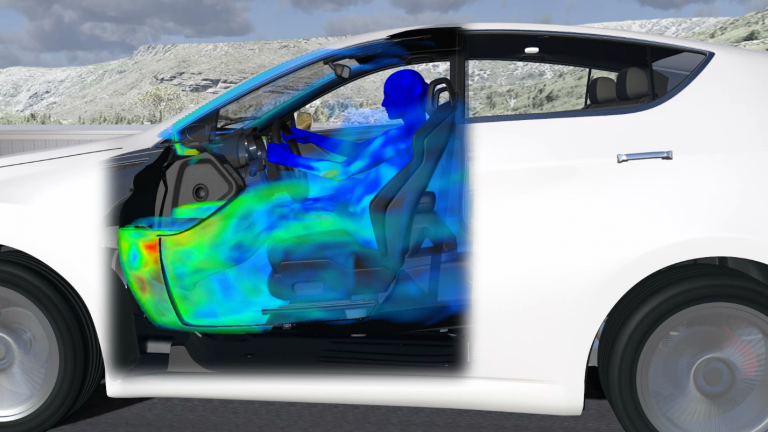

Climate Control and Cabin Comfort

Every detail counts for the driver and passenger experience. Noise, vibration, temperature and comfort are just some of the factors that vehicle cabin designers must control and optimize. Heating, ventilation and air conditioning (HVAC) systems are especially crucial, because they consume significant amounts of energy and impact the vehicle range. With simulation, engineers can optimize the design of HVAC and other interior systems to ensure thermal comfort with minimal power consumption.

Concept Structure Engineering

The concept is the first stage of design, but decisions made here have implications for the entire development cycle and can make the difference between a winning design and one that doesn’t make it off the drawing table. Simulation at the concept stage lets engineers analyze the performance of the vehicle structure before constructing a physical prototype. Different design variations can be easily modified and simulated without having to perform tedious re-meshing, enabling fast trade-off studies of performance.

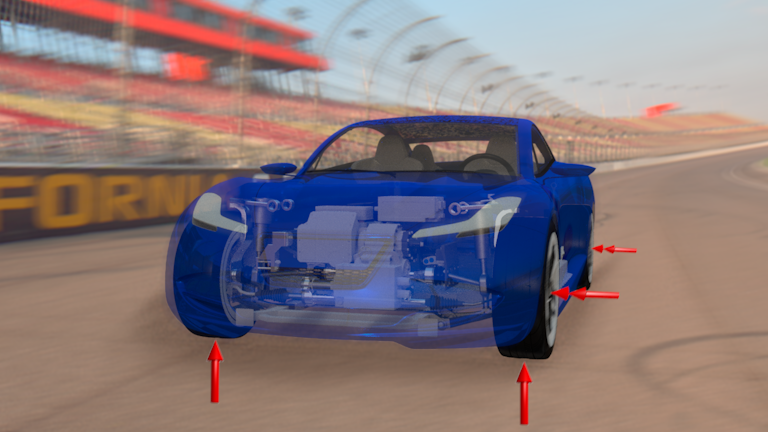

Vehicle Dynamics

Whether the driver wants something smooth and easy or sporty and fun, vehicle dynamics are crucial to meeting customer expectations for handling and ride experience. Steering, suspension and powertrain components can be optimized in isolation or as part of a larger system with multibody dynamics simulation. Vehicle dynamics can be investigated on rough road conditions and with challenging driver behavior quickly and safely on a virtual twin. Hardware-in-the-Loop (HiL) and Man-in-the-Loop (MiL) simulation offers real-time feedback on handling and ride within a driving simulator to provide insight on the end user experience.

Powertrain Strength, Durability & Vibration

The role of the powertrain is to deliver power from the energy source to the wheels as efficiently as possible. Engines, motors, transmissions and all powertrain components have to last for hundreds of thousands of kilometers under constant stress. Simulation helps engineers to understand the transfer of torque through the powertrain, as well as other important factors and identify potential sources of fracture or wear. Optimizing the powertrain increases the reliability of the vehicle.

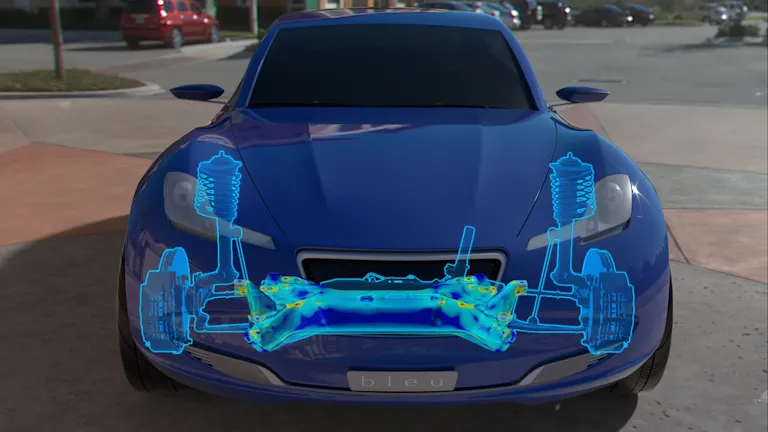

Chassis & Suspension Strength, Durability & Vibration

With every bump in the road, considerable forces propagate through the vehicle. The aim of the engineer is to ensure that these forces are distributed to minimize the impact felt by the passengers and the wear caused to suspension and body elements.

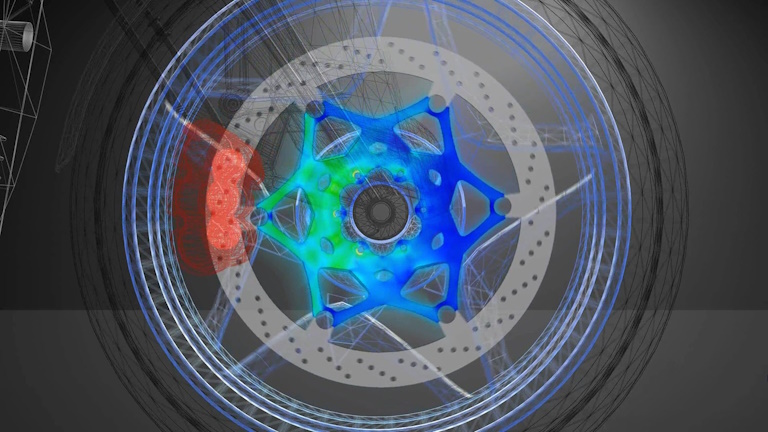

Brake System Engineering

Brake performance is crucial to vehicle safety. Brakes need to be capable of stopping the weight of the vehicle and its load even at high speed in wet, muddy or icy conditions. Simulation reveals the stopping power of brake designs under challenging scenarios, without having to test a physical prototype. Brake disk and pad wear can also be analyzed to understand durability and brake dust pollution, and thermal and aerodynamic simulation also shows how brakes heat up and are cooled to help design overall braking systems.

Vehicle Thermal Management

Managing engine heat has long been one of the most important factors in ensuring reliability. The transition to electric vehicles introduces new cooling needs, with motors and batteries generating heat – and in the case of batteries, there is the additional need for heating in the winter. Designing effective cooling & heating systems requires an understanding of the interior coolant as well as the airflow around and through the vehicle body. Thermal simulation reveals heat generation and the effectiveness of cooling systems in different weather conditions and scenarios.

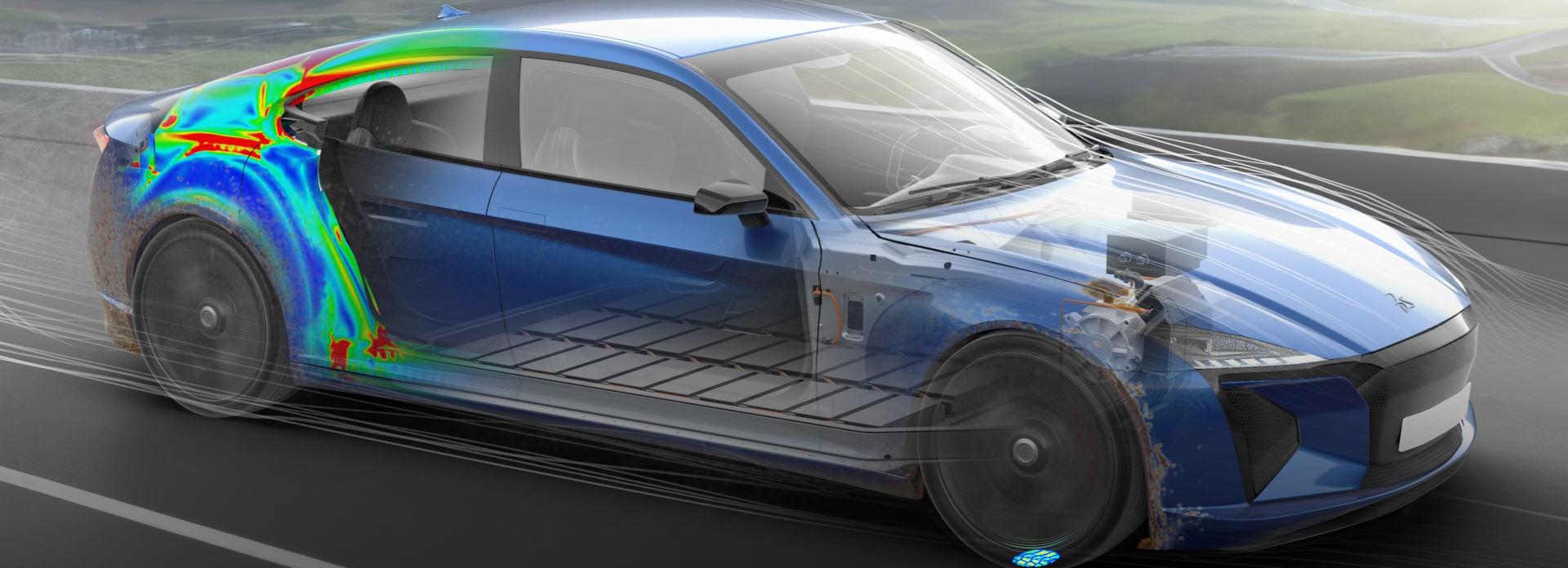

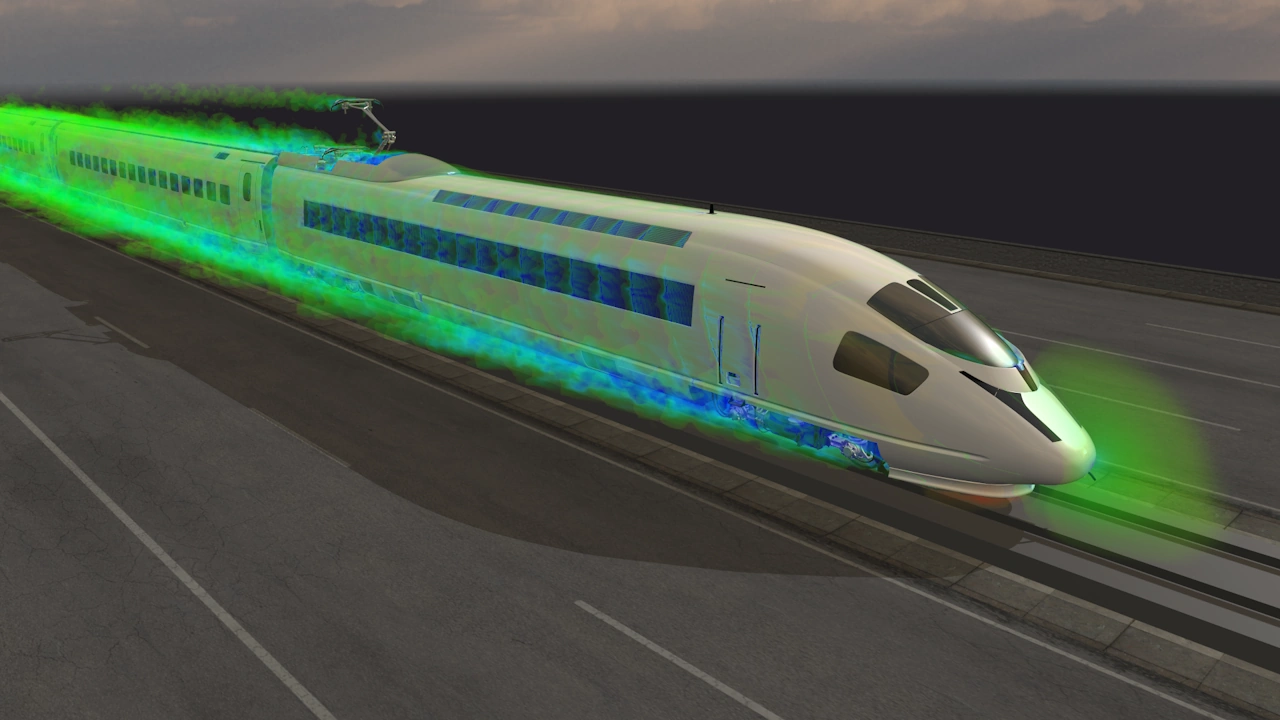

Vehicle Aerodynamics

Aerodynamic drag has a huge impact on the efficiency and ultimately the range of a vehicle. Traditionally, aerodynamics requires significant amounts of wind tunnel testing to analyze and improve. Simulation allows aerodynamics to be modeled at any stage of development, from concept onwards, without costly and time-consuming physical testing, and offers a more realistic representation of real-world driving performance than a wind tunnel can alone.

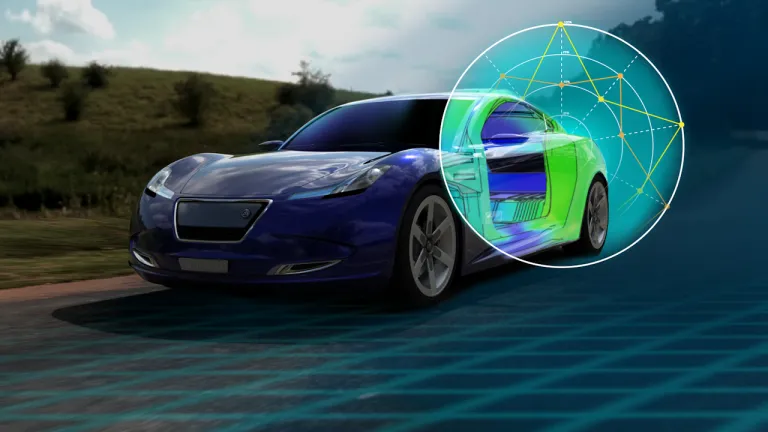

Vehicle Electronics

By 2030, electronic systems are expected to make up half the total cost of a vehicle. Safety systems, engine control, autonomous and driver assistance (ADAS) and infotainment are just some of the systems integrated into modern vehicles, and all these systems operate in close proximity without interference or data errors. Electromagnetic simulation allows electronic engineers to analyze electromagnetic compatibility (EMC) and signal and power integrity (SI/PI) of on-board electronics and resolve any problems. At the system-level, it also helps integrators to find the best placement for antennas and sensors, and to mitigate crosstalk and co-site interference between on-board systems.

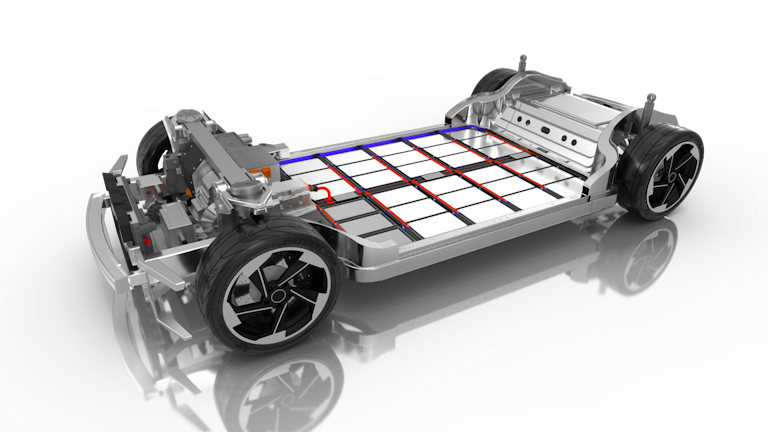

Battery Engineering

The battery is the largest and most expensive component in an electric vehicle. Manufacturers compete hotly on range, charging speed and cost, all of which are determined in large part by the performance of the battery. Simulation can be used to design batteries, from the individual cell up to the entire battery pack, revealing the complex 3D electrochemical phenomena of charging and discharging. Multiphysics simulation also helps design other aspects of the battery module, including crashworthiness and cooling.

Transportation & Mobility Segments

The transportation and mobility sectors encompass various segments, each benefiting from simulation to enhance their performance, safety, and efficiency.

- Passenger cars and light trucks are designed for diverse purposes, from economy to luxury, ensuring a comfortable ride.

- Heavy trucks, vital to the global economy, rely on simulation to endure the demands of logistics.

- Buses are evolving with advanced comfort and emission standards through simulation, including hybrid and electric models. Trains, as a sustainable transport mode, use simulation to optimize components and systems for both passenger and freight services.

- In motorsports, simulation is crucial for maximizing speed, handling, and durability under extreme conditions. Motorcycles, from scooters to racing bikes, leverage simulation for tailored aerodynamic and dynamic performance.

- Lastly, bicycles and active mobility solutions, including e-bikes and cargo bikes, utilize structural and electromagnetic simulation to meet rising complexity and safety expectations. Simulation plays a pivotal role in advancing these transportation segments.

SIMULIA Industry Solutions for Transportation & Mobility

Almost everything that has enabled modern society to evolve and prosper depends on mobility. The early innovators empowered the world with a previously unforeseen freedom of movement. But today's automotive & mobility industries are facing a massive revolution. Explore how today's OEMs and new innovators alike are entirely redefining the future of mobility with industry-leading 3DEXPERIENCE solutions.

FAQs about Transportation and Mobility Solutions

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering