Vibro-Acoustics Simulation

Simulation and analysis of noise and vibration across the entire audible frequency range

Full Spectrum Vibro-Acoustics Simulation

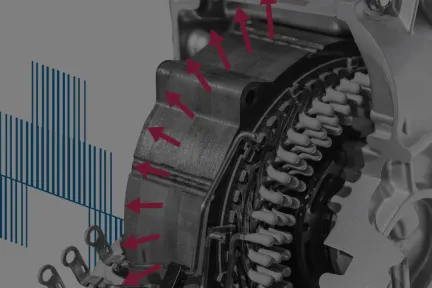

Noise and vibration analysis is becoming increasingly important in virtually every industry. The need to reduce noise and vibration can arise for many reasons: government legislation, lightweight designs, materials, detectability, fatigue failure or increased competitive pressure.

In many applications, the noise from a product is perceived by a person who either uses this product or is exposed to noise generated by this product. It is, therefore, often necessary to consider noise and vibration performance across the entire audible frequency range. This requires a combination of vibro-acoustic simulation methods including both, deterministic, mesh-based methods along with statistical wave mechanics-based methods

The choice of vibro-acoustic simulation method also depends on the design stage of a product. Earlier in the design cycle, there is often less detail available about a product. The use of fast statistical vibro-acoustic simulation methods can help ensure that noise and vibration performance is built into a product from the very early concept design stages. The earlier in the design cycle that you can analyze a product, the more likely it is that your noise and vibration recommendations influence the final design. This also helps you reduce the risks associated with discovering noise and vibration problems late in the design cycle when last-minute design changes can introduce significant costs and schedule delays.

SIMULIA Vibro-Acoustics Simulation Key Benefits

Reduced Development Cost and Time to Market

Vibro-acoustic simulation reduces development costs and ensures that noise and vibration performance is built into a product at the design stage, before physical prototypes have been created.

Understand Complex Systems

Vibro-acoustic simulation helps you diagnose the dominant transmission paths between sources and receivers and ensures that you don’t waste time, money, and mass treating non-dominant paths.

Find and Resolve Problems

Vibro-acoustic simulation helps you reduce the risk of discovering noise and vibration problems late in the design cycle when last-minute “band-aid” fixes can be expensive and non-optimal and introduce schedule delays.

Realistic Immersive Product Evaluation

Vibro-acoustic simulation enables you to listen to the sound of your product when placed in a virtual acoustic space long before any physical prototypes exist. This includes both binaural auralization and full 3D spatial audio with VR head tracking.

Reduced Work through Automation

Automation ensures that the process of creating and solving a model can be pipelined and automatically repeated. The reduced need for manual changes to models when upstream inputs change enables you to spend time solving noise and vibration issues instead of wasting time manually updating models.

Optimized Designs

Automated pipelined processes enable you to evaluate many different designs quickly, efficiently and automatically. Fully inbuilt optimization and parameter variations enable you to find optimal designs that are lightweight, quiet and robust.

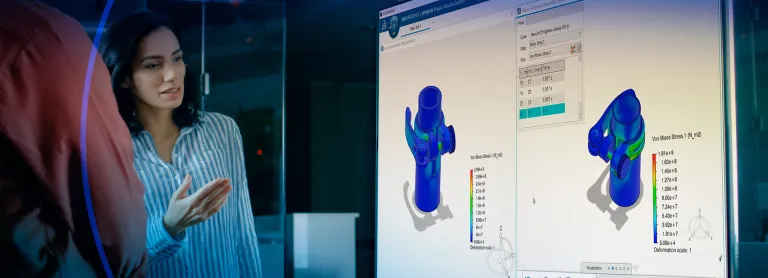

Vibro-Acoustics Simulation Software Product

SIMULIA develops advanced software that can be used to simulate noise and vibration performance across the entire audible frequency range. Simulia vibro-acoustics simulation software is available on the 3DEXPERIENCE platform and standalone.

Start Your Journey

The world of vibro-acoustics is changing. Discover how to stay a step ahead with SIMULIA

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering