Deliver Low-Carbon Energy With Small Modular Reactors

Lower nuclear energy costs by scaling up affordable and configurable small modular reactors through a unified digital platform.

The Role of Small Modular Reactors in Decarbonizing the Energy Industry

By 2050, global energy consumption will grow by nearly 50%1. As countries seek to implement clean and innovative solutions, the increased use of renewable sources coupled with nuclear energy has the potential to meet additional demand and displace existing fossil fuels.

To decarbonize the power industry, energy leaders are bringing small modular reactors (SMRs) to life that will play a bigger role in the energy mix. Thanks to the use of passive safety systems and smaller fuel inventories, SMRs also reduce the risk of human error and interventions in the case of accidents.

However, licensing and certification challenges remain. To address these complexities and scale up affordable and configurable nuclear energy, companies are turning to digitalization to gain information reliability and traceability.

Digitalize to Decarbonize

Bring small modular reactors to life while delivering low-carbon nuclear energy.

Download our ebook for more insights.

Digitalize for Safety and Efficiency

If nuclear is to continue to play an important role in powering the world, companies must instill confidence in citizens that their operations are safe. This is where digitalization comes in.

Streamline licensing processes

Nuclear regulations are different across countries, which not only affects the safety demonstration of the power plant, but also the technical safety measures. Standardization through a unified platform is the key to navigating licensing practices.

Simplify the safety case

By using a single platform to demonstrate the safety of the power plant, companies can produce a detailed safety case for licensing reviews while reducing extensive time and resources.

Strengthen safety demonstrations

Through a model-based approach, stakeholders can ensure full traceability of all changes during the virtual review of the safety case by regulators.

- Streamline licensing processes

- Simplify the safety case

- Strengthen safety demonstrations

Streamline licensing processes

Nuclear regulations are different across countries, which not only affects the safety demonstration of the power plant, but also the technical safety measures. Standardization through a unified platform is the key to navigating licensing practices.

Simplify the safety case

By using a single platform to demonstrate the safety of the power plant, companies can produce a detailed safety case for licensing reviews while reducing extensive time and resources.

Strengthen safety demonstrations

Through a model-based approach, stakeholders can ensure full traceability of all changes during the virtual review of the safety case by regulators.

Harmonize Three Pillars of SMRs

In addition, digitalization harmonizes the three pillars that form the core of SMR power plants: Modularization, productization and standardization.

- Modularization

- Productization

- Standardization

Modularization

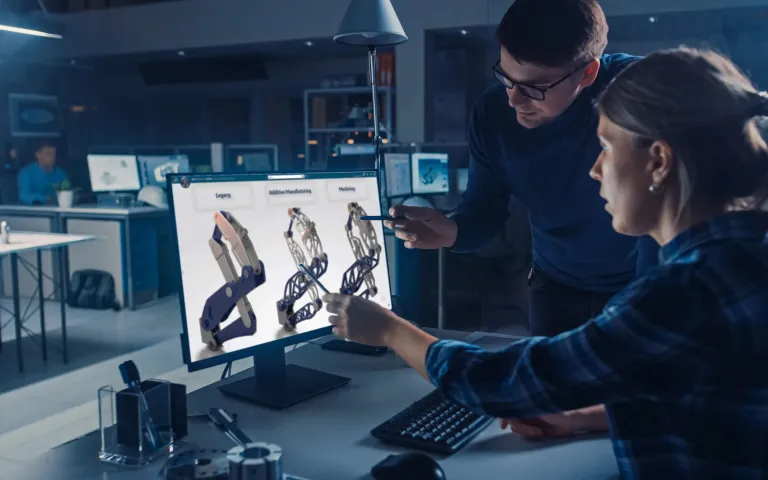

Through off-site fabrication of components, modularity offers the ability to make SMR plants configurable and more affordable. However, this needs to be planned from as early as the conceptual design phase. By using a unified platform, companies can collaborate with module manufacturers to develop the plant architecture according to the requirements, thus shortening construction time, costs and waste.

Productization

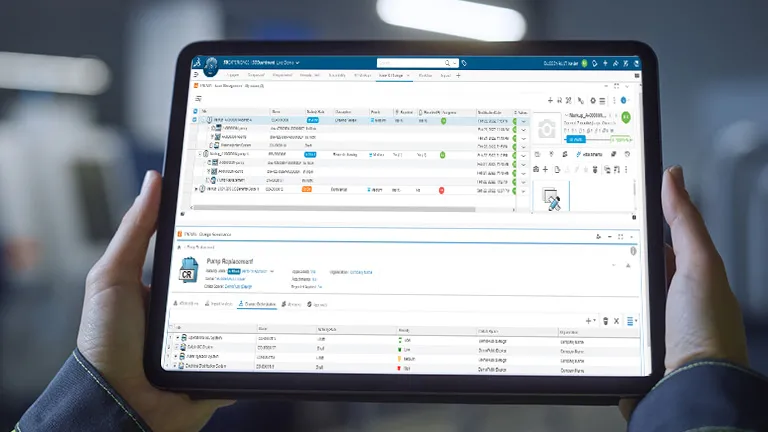

SMRs bring the promise of plant-as-a-product, designed and manufactured with standard product lines, and operated and maintained as a fleet. With digitalization, all stakeholders can move towards model-based systems engineering (MBSE) to simulate and validate product designs in multiple configurations. By leveraging the virtual twin of the plant, companies can make informed decisions and fast track the licensing process.

Standardization

Standardization aims to ensure safe, reliable, and sustainable SMRs at an affordable cost. Through a single platform, companies can develop SMRs as a fleet to reduce costs while taking into account site specificities and optimizing their processes through multi-physics simulation. These processes can include assembly, commissioning, operations, maintenance and dismantling.

Digitalize for Clean Energy

As more countries move away from fossil fuels, nuclear energy continues to gain traction as a flexible, dispatchable energy source. Small modular reactors are a viable solution to produce decarbonized and cost-effective electricity to compensate for the intermittent nature of renewable sources such as wind and solar.

SMRs including microreactors will play an important role in ensuring the security of the world’s energy supply as well as its transition to net zero. It’s time to unpack the challenges and opportunities in nuclear and move towards a low-carbon future.

Advantages of Small Modular Reactors

Design Safer and Smarter Advanced Nuclear Reactors

Optimize the design of small modular reactors with the virtual twin experience.

Explore our Energy Solutions

1 Source: US EIA (Oct 2021)

FAQ About Small Modular Reactor Technology

A nuclear reactor is a device that generates energy through the process of nuclear fission, where atoms are split to release energy in the form of heat. This heat is used to produce steam, which powers turbines to generate electricity. Nuclear reactors are a key source of low-carbon energy in the global energy mix.

Compared to traditional nuclear reactors, small modular reactors (SMRs) offer a host of advantages. They utilize a modular design, where pre-fabricated components are transported and assembled on-site, reducing construction costs and time. SMRs excel in efficiency, allowing for easy adjustment to meet energy demands. Additionally, their compact size enhances safety by mitigating the risk of major accidents.

Small Modular Reactors (SMRs) are compact nuclear power plants, considerably smaller than conventional reactors. They are engineered to enhance safety, efficiency, and cost-effectiveness, potentially transforming the landscape of nuclear energy production. Multiple countries, including the United States, Canada, Russia, the United Kingdom, China, and South Korea, are presently involved in the development of various SMR designs.

The primary regulatory challenges for Small Modular Reactors (SMRs) include navigating complex licensing processes and complying with different safety regulations across countries. These hurdles can delay development and increase costs, but digitalization and standardization are helping to streamline these challenges for quicker approval.

Small modular reactors (SMRs) represent a compact and improved form of nuclear reactor technology compared to traditional counterparts. They offer enhanced efficiency and simplified construction. SMRs encompass diverse types, such as light water reactors, high-temperature gas-cooled reactors, molten salt reactors, and fast reactors, each with distinct pros and cons. It is crucial to comprehend these distinctions to select the most suitable type for specific applications.

| Aspect | Small Power Fission Reactors | Traditional Nuclear Plants |

| Size and Capacity | Smaller size with lower power output (typically under 300 MW). | Larger size with high power output (typically over 1,000 MW). |

| Construction Time | Faster to build due to modular design. | Longer construction time, often spanning a decade or more. |

| Cost | Lower capital costs due to modular construction and smaller scale. | Higher capital costs due to size, complexity, and construction timelines. |

| Deployment Flexibility | Can be deployed in remote or off-grid locations. | Primarily suited for large, centralized energy grids. |

| Safety Systems | Advanced passive safety systems with fewer moving parts. | Traditional safety systems with more active controls. |

| Fuel Use and Waste | Typically designed for more efficient fuel use, producing less waste. | Larger fuel consumption and higher levels of nuclear waste. |

| Licensing and Regulation | Subject to more streamlined regulatory pathways in some regions. | More complex and stringent regulatory processes. |

| Maintenance and Operation | Lower operational costs and easier maintenance due to size and design. | Higher operational costs and more complex maintenance requirements. |

| Market Focus | Targeted at small grids, industrial sites, or isolated communities. | Primarily used for large-scale power generation for urban and industrial areas. |

Related Content

Sustainable Energy

How to move to a next-generation energy landscape to reduce your energy use footprint.

Generate Clean Energy Profitably With Sustainable Wind Turbines

Win the clean energy race by minimizing the carbon footprint of wind turbines with virtual twin technology.

Clean Energy Technologies: Powering Up Innovation

Learn how you can revolutionize low-carbon technologies with an innovative platform.