Reformulate Alternative Materials for a Safer, Cleaner Future

Discover the digital edge in research, development and manufacture of alternative materials for a circular, sustainable business.

Key Strategies for Sustainable Raw Material Management

Global materials use is projected to double from 79 gigatons (Gt) in 2011 to 167 Gt in 2060(1). This calls for an urgent and strategic review of raw material usage, energy-efficiency strategies and waste reduction practices. With the increasing consumer and regulatory demands, the present sustainability imperative culminates in reformulating alternative materials with higher recyclability value and bio-based properties for sustainable production.

Our sustainability kit simplifies the complexities of product reformulation to help you get started in your transition to circularity.

Digital Reformulation: The Future of Alternative Materials

Discover the strategies that drive innovation and growth in product reformulation.

Incorporate Alternative Materials Early

Recent regulatory pressures by the European Green Deal calling for safer and more sustainable chemicals(2), a ban on plastic food packaging in France in January 2022(3) and new packaging taxes introduced in the UK(4) intensify the search for safer alternative materials.

An aggressive shift is needed to alter and develop new biomaterials and more sustainable products through a transformation in research and development. New sustainable ingredients with superior properties and performance, less hazardous chemical emissions (especially in biomedical 3D printing), and safer bio-ingredients can be developed and incorporated early in the design phase. Doing it right at the beginning cuts waste, prolongs use and ensures that materials can be safely returned to the environment after use.

Types of Sustainable Packaging Materials

Biodegradable Materials

Organic substances that naturally break down over time.

Recyclable Materials

Easily processed into new products, such as cardboard and certain plastics.

Reusable Materials

The most eco-friendly option, as they reduce waste. Glass containers serve as a key example.

Recycled Materials

Choose packaging made from 100% recycled or raw materials to lower environmental impact.

Achieve Materials Breakthroughs in Final Products

Virtual twin technology made it possible to explore, simulate and test new sustainable alternatives in ways we could only imagine before and turn them into more eco-friendly packaging products, such as ultralight glass, bioplastics and sustainable cardboards.

- Ultralight Glass

- Bioplastics

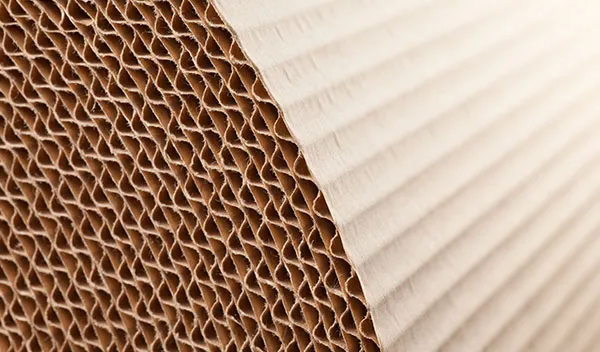

- Sustainable Cardboards

Ultralight Glass

The weight of glass bottles has been reduced by 40%(5) in the last 30 years as technology advanced. For example, Ardagh Group's ultralight bottles project pioneered research and testing of coatings by simulating coatings interaction and efficacy with the surface glass through the virtual twin. This reduced raw materials and energy used, minimized risks and timescales of new coatings' development and maintained materials quality and strength.

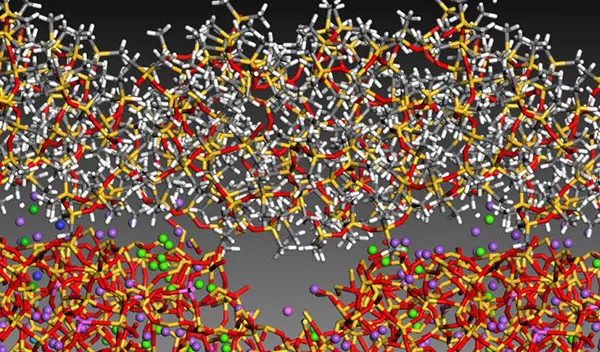

Bioplastics

Renewable biomass sources are superb for bioplastics but they are costly to manufacture. With many global brands pushing to meet this demand, molecular simulations help researchers design and experiment with plastic alternatives without expensive prototyping. This brings cleaner, more sustainable packaging solutions to the market with speed and at scale.

Sustainable Cardboards

Sustainable production includes using materials from sustainable sources, reducing waste and optimizing designs. Metsä Board simulated its production to shorten prototype testing and product development processes for cost savings and waste reduction. The 3DEXPERIENCE platform enabled Metsa Board to design, simulate and test lighter board grades with higher recyclability value while providing a complete product lifecycle assessment.

The 3 Main Considerations of Sustainable Packaging Materials

1. Efficient Production Processes : Collaborate with companies that prioritize sustainable supply chains and production efficiency.

2. Reusability and Circular Economy: Opt for reusable packaging to extend its lifecycle, supporting a circular economy.

3. Ethical Labor Practices: Assess the manufacturers, working conditions, and social and economic aspects involved in your packaging production.

Digitalize for Effective Results

The most effective way to accelerate reformulation is through digitalization. Digitalization is central to any modeling, predicting and understanding of materials' substitution and development as it lists, screens and identifies the right, compliant raw materials to replace the uncompliant ones. Digitalization also helps run an efficient formula management system and create an optimum testing environment to gain:

Full Control and Real-Time Processing

Full control, complete visibility and traceability of formulations across all stakeholders, and real-time processing for speed and accuracy.

Seamless Data Flow for Lifecycle Assessment

Seamless data flow for comprehensive product lifecycle assessment that prioritizes materials with the least environmental impact and harmonizes (re)formulation capabilities with safety, regulatory and environmental compliance.

Simulation and Virtual Testing

Simulation and virtual testing of materials as opposed to physical testing, which takes up far more resources, cost and time.

Our infographic shows quick wins in the circular economy through digitalization.

Whatever your sustainability goals may be, it is time to design with the end in mind. Take the alternative materials route and start shaping products for a cleaner and safer future.

Explore our Solutions

1 Source: OECD

2 Source: Cefic

3 Source: World Economic Forum

4 Source: Gov.UK

5 Source: GPI

FAQ About Green & Recyclable Packaging

In the realm of sustainability, businesses are increasingly embracing eco-friendly packaging solutions like sustainable materials to reduce their reliance on traditional plastic packaging.

These innovations, including custom eco-boxes and organic clothing packaging, play a crucial role in mitigating environmental impact, lowering greenhouse gas emissions, and advancing a greener future. Discover how sustainable design is reshaping the packaging industry.

The foundation of green packaging rests on five fundamental principles known as the 5 R's:

- Reduce,

- Reuse,

- Recycle,

- Renew,

- Redesign.

Eco-friendly packaging materials are made from plant-based alternatives that match plastic's durability while being environmentally friendly. For example, mushroom packaging combines agricultural waste with mycelium to create sturdy containers that decompose naturally within 45 days. Water-activated paper tapes replace plastic adhesives, offering recyclable and strong sealing solutions. Additionally, kraft paper mailers reinforced with natural starches provide excellent protection for shipped goods, making them a sustainable choice.

Five planet-friendly food packaging choices that prioritize both environmental well-being and your health:

- Glass containers: Versatile and eco-conscious.

- Stainless steel: Durable and sustainable.

- Bamboo: A renewable and eco-friendly material.

- Rice husk: A biodegradable and waste-reducing option.

- Gelatin films: Innovative and environmentally sensitive solutions.

Eco-conscious packaging and alternative materials play a crucial role. This encompasses the utilization of biodegradable, compostable, and recycled materials, such as:

- paper pulp and plastic substitutes,

- in crafting packaging,

- boxes,

- and shipping supplies.

Embracing these methods enables companies to markedly curtail waste and greenhouse gas emissions. Explore insights into top eco-friendly and sustainable designs, along with instances of environmentally responsible packaging solutions, offering a comprehensive roadmap for those striving to create a positive environmental footprint.

Packaging innovation reduces environmental impact by using sustainable materials, minimizing waste, improving recyclability, and optimizing designs to lower resource consumption and carbon emissions.