Manufacturing Definition Creator

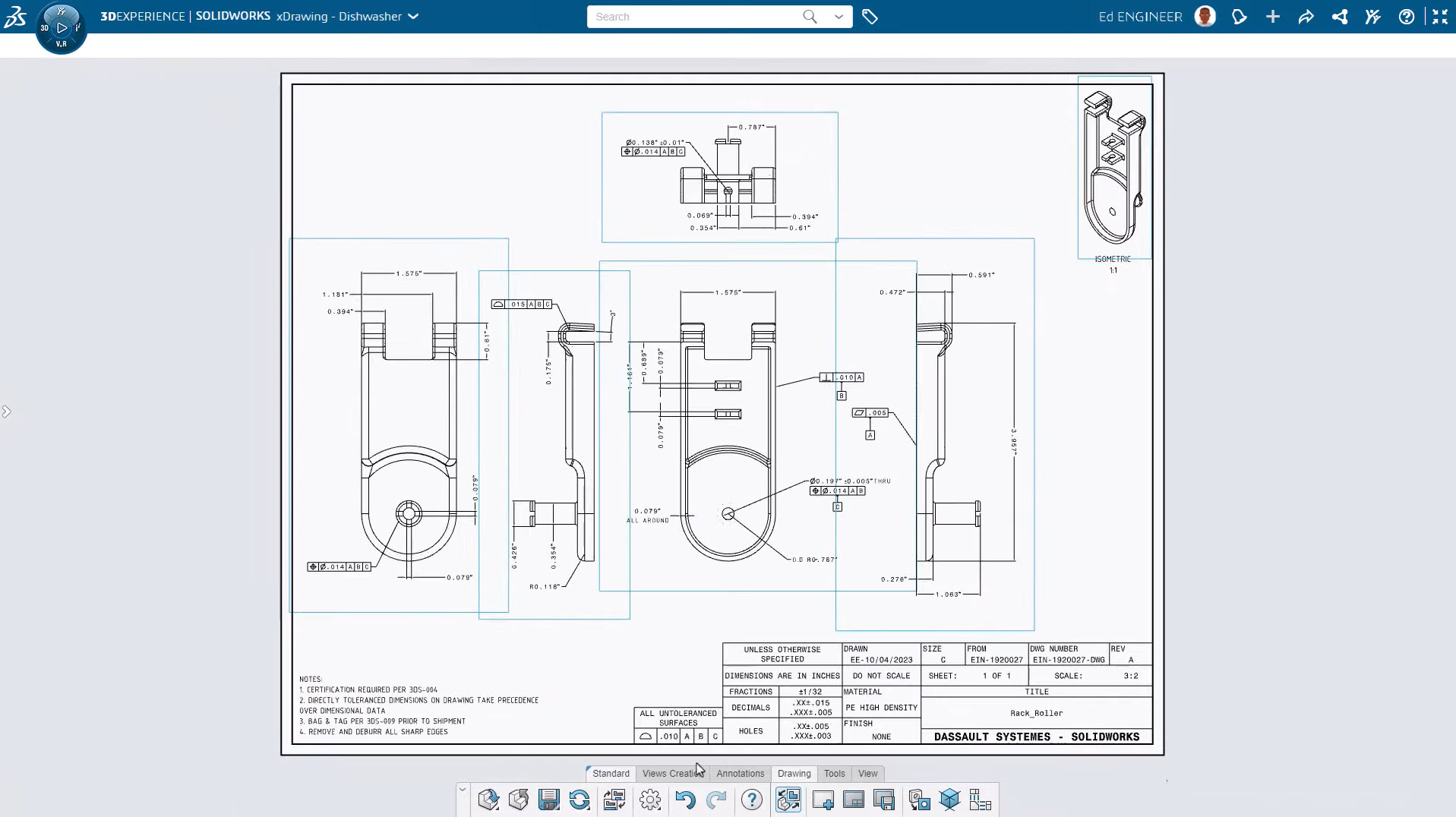

Effortlessly define 3D models and quickly generate the corresponding 2D drawings

Revolutionize Product Definition

The manufacturing definition is a browser-based solution connected to the 3DEXPERIENCE® platform which defines, organizes, and communicates design requirements for manufacturing.

Created for designers and engineers to streamline the definition of products in a more integrated and flexible way.

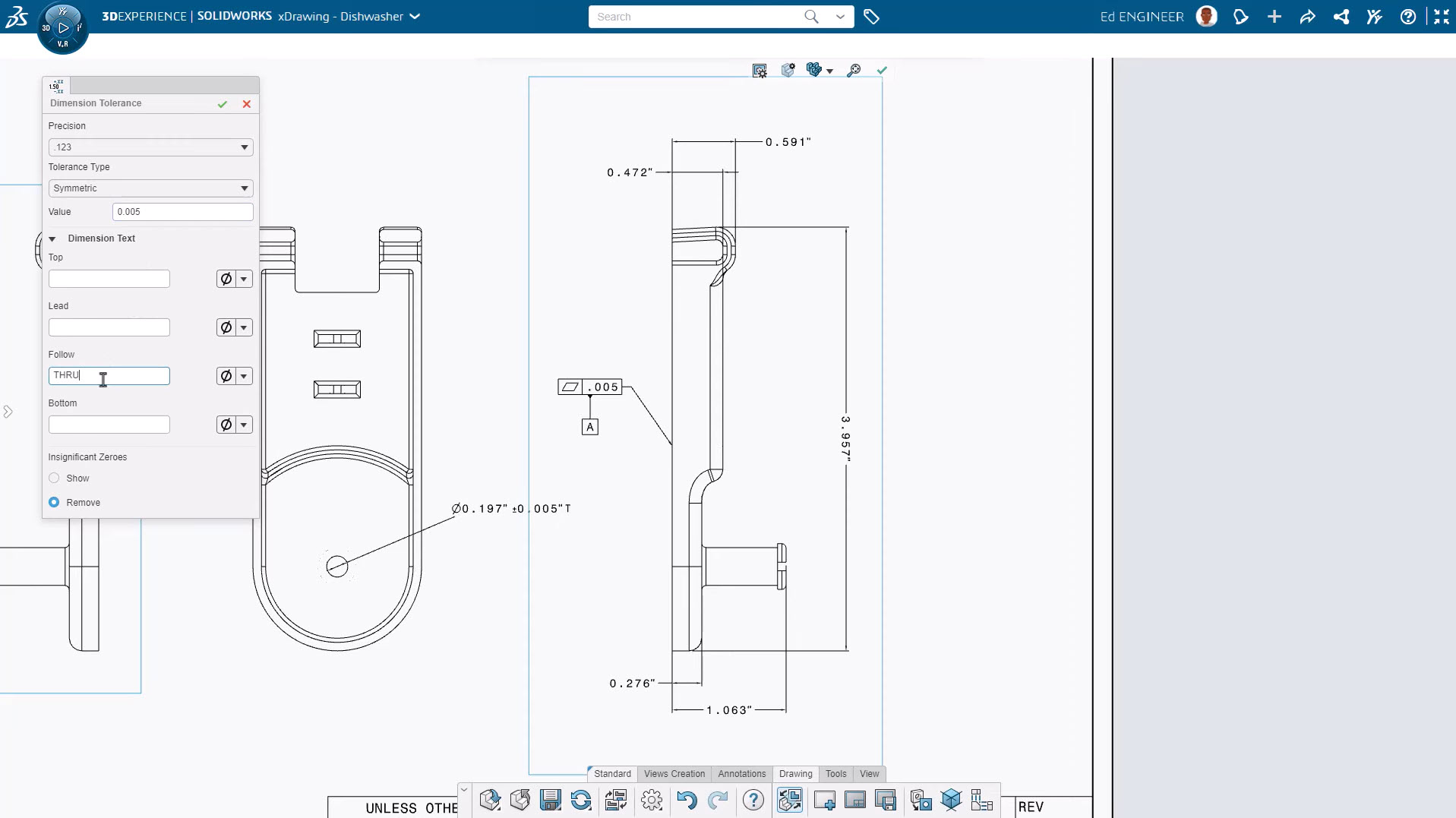

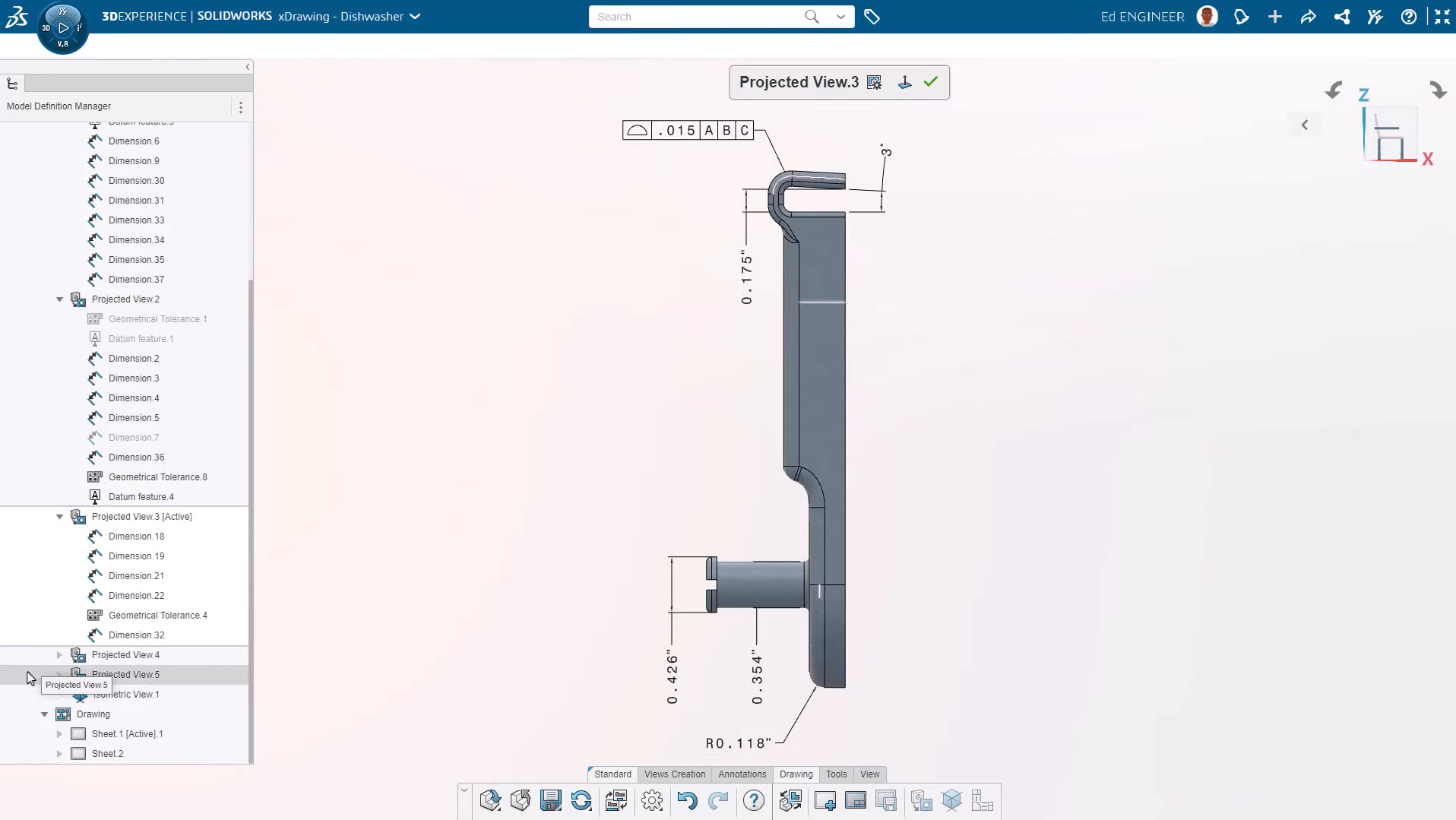

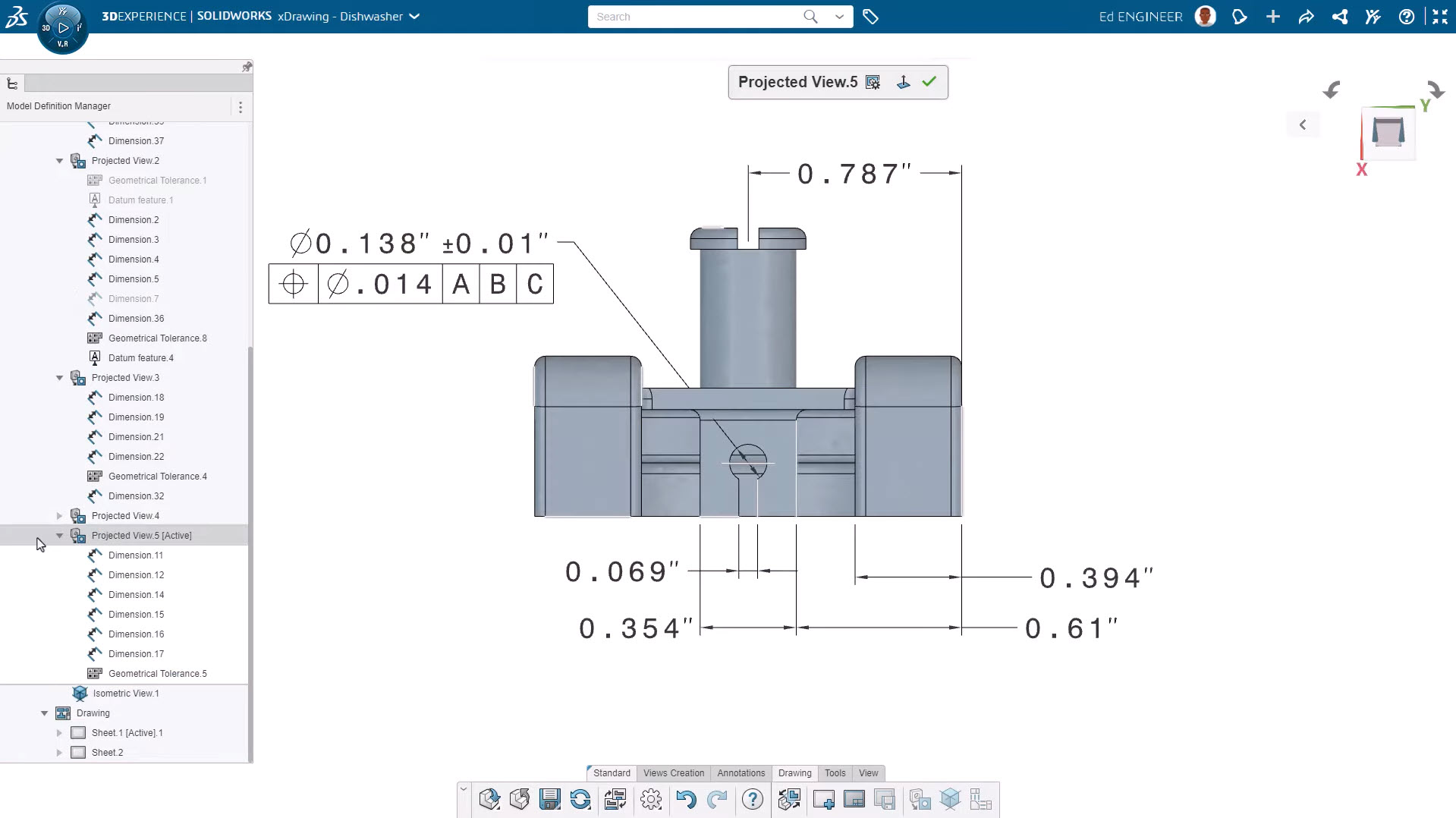

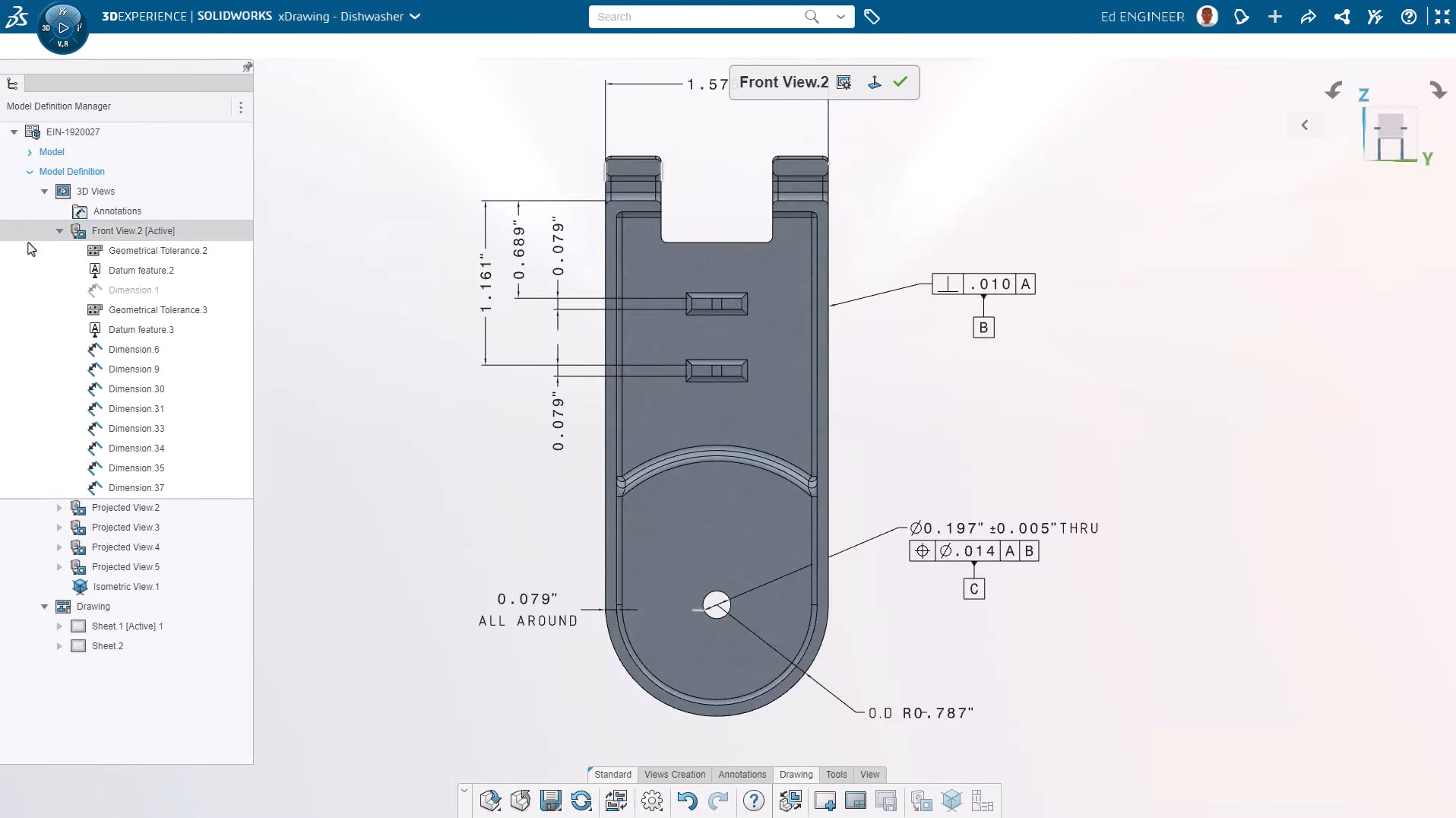

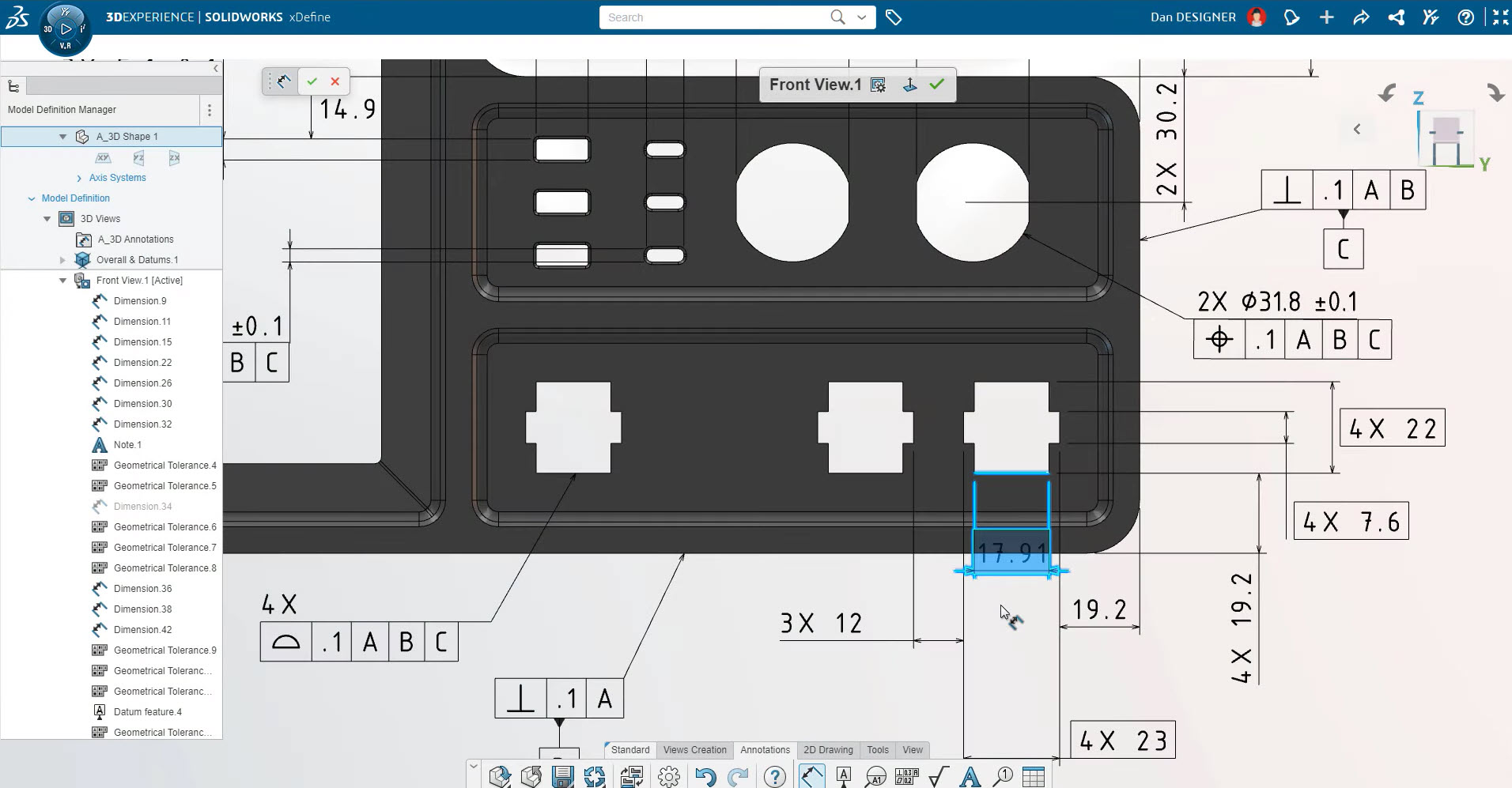

Leverage model-based workflows to create a single source of truth between 2D and 3D definition with annotations, dimensions, and tolerances that always stay up-to-date and synchronized across both forms of definition

Revolutionizing Precision and Efficiency

Experience a paradigm shift in manufacturing processes with our cutting-edge Manufacturing Definition Creator Software. This innovative tool is designed to redefine precision and efficiency in the manufacturing industry. Seamlessly create and refine manufacturing definitions, ensuring accuracy and clarity at every stage of production.

Our software empowers engineers, designers, and manufacturers to streamline the definition process, minimizing errors and maximizing productivity. With intuitive features and a user-friendly interface, you can effortlessly generate comprehensive manufacturing definitions that align seamlessly with your production requirements.

Stay ahead of the curve in the competitive manufacturing landscape by embracing our state-of-the-art software. From defining intricate processes to optimizing workflows, our Manufacturing Definition Creator solution is the key to unlocking a new era of manufacturing excellence. Elevate your operations, reduce lead times, and enhance overall product quality.

Elevate your design potential with SOLIDWORKS 3D drawing and design software

Reduce shop floor inquiries by providing structured views for improved interpretation of design specifications.

Take advantage of a built-in data management and collaboration features on the 3DEXPERIENCE

Effortlessly generate 2D layouts by utilizing existing captured views, annotations, dimensions, and tolerances without additional steps.

Standout Features of Manufacturing Definition

- Enhance productivity using an integrated 2D and 3D definition system.

- Streamline GD&T workflows to reduce manufacturing problems.

- Efficiently organize and review critical data using intuitive, accessible 3D views.

- Boost productivity and minimize rework with a unified 2D and 3D solution.

- Prevent errors between model-based and drawing-based practices by employing 3D views on 3D drawings.

- Facilitate collaboration and ensure stakeholders remain updated through effortless 2D PDF sharing.

Manufacturing Definition Creation is part of the SOLIDWORKS Cloud Offer

Frequently Asked Questions

The Manufacturing Definition creator is not currently available for purchase as a single role. However, it is included in the SOLIDWORKS Cloud offer, a set of applications created by the SOLIDWORKS team for 3D Design and lifecycle management solution.

Your data is securely stored in the 3DEXPERIENCE platform, granting access to current files. You have control over access to data and receive live design updates through instant notifications.

In addition we perform daily customer data backups to ensure the safety and security of your data.

Yes! With the 3DEXPERIENCE platform using the 3DSwymer role, which is included in the SOLIDWORKS Cloud offer, you have the opportunity to foster collaboration between stakeholders, facilitating a dynamic and innovative working environment. Here's how:

- Store and share data, track your progress and monitor your KPIs using personalized dashboards

- Actively involve team members as you grow and build a true online community of users and contributors

- Suggest ideas and track progress through idea funnels

Manufacturing supplies, integral to facility operations, aren't primary raw materials for product creation. They encompass a diverse array of items, ranging from cleaning supplies to machine lubricants. These are essential design requirements, often managed in a shared database for efficient tracking and procurement.

Manufacturing production encompasses efficient strategies for producing and selling goods, going beyond material lists. Three prevalent approaches are make to stock (MTS), make to order (MTO), and make to assemble (MTA). These methods impact labor costs, inventory management, overhead, customization, production speed, and order fulfillment.

Manufacturing design, often referred to as Design for Manufacturing (DFM), is an engineering practice focused on the ease of manufacturing a product and its cost-effectiveness. It involves designing parts, components, or products with the end goal of ensuring that they can be manufactured efficiently, without compromising quality. DFM takes into account aspects such as assembly processes, testing, and potential factory constraints. By doing this in the early design stages, costly production changes can be prevented, and overall manufacturing process efficiency can be improved. This approach is part of the broader Design for Excellence (DFX) philosophy.

Original Design Manufacturing (ODM) is a production model where a company, the ODM, designs and manufactures a product that is then rebranded and sold by another company. The ODM possesses specific industry expertise, allowing it to take on the entire product development process, from research and development (R&D) to manufacturing.

Need more information? - please check our full FAQ here