Discover our guide about Mechanical Design Software

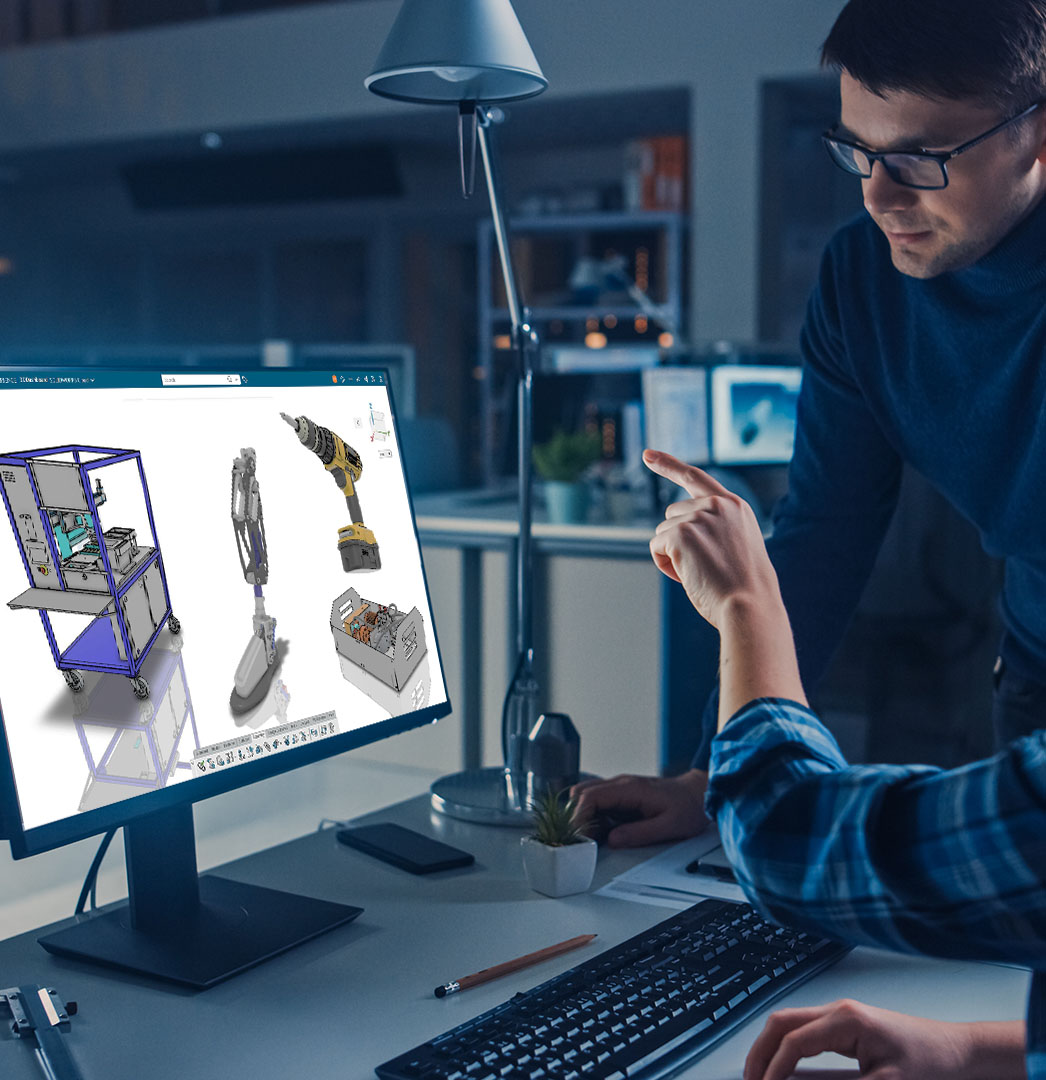

Professional engineers and designers rely on cutting-edge mechanical design software to help them create products. Having a good knowledge of the latest machine design software is a crucial skill for any mechanical engineer or designer.

Advances in mechanical engineering and product design are driven by powerful computer aided design (CAD) technology. These digital tools speed up and streamline the product development process and encourage creativity and innovation. Join us as we take an in-depth look at just why CAD machine design software is so integral to so many industries across the globe.

What is a mechanical design software?

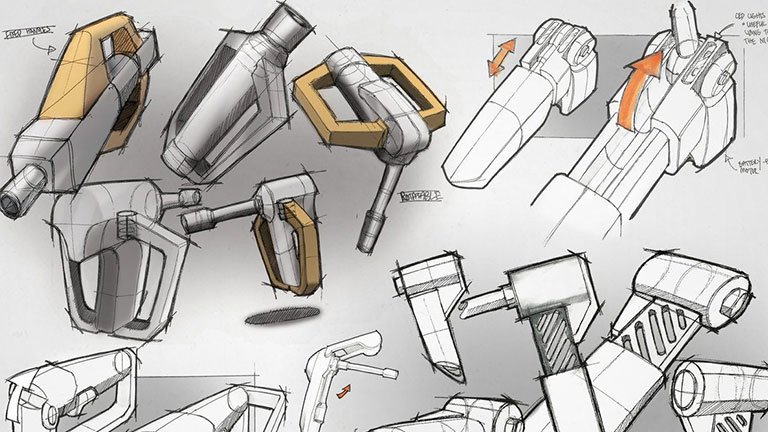

Also known as mechanical design automation (MDA), mechanical design software enables engineers and designers to produce intricate, highly complex technical drawings. These drawings convey information on all the manufacturing and engineering specifications of a certain product, component, or piece of machinery. Technical drawings also contain information regarding tolerances, materials, dimensions, and processes.

Mechanical design software allows engineers and designers to create incredibly detailed, highly accurate technical drawings as either two-dimensional ‘pen and ink’ type sketches or render life-like three-dimensional models using 3D CAD modeling software.

Discover our mechanical design solutions in the store

Ever since the ground-breaking CATIA was first released in 1982, Dassault Systèmes has been setting the standard for CAD design programs. Now in its sixth version. CATIA has been expanded to include a suite of programs designed to meet the needs of both experienced and entry-level designers and engineers.

CATIA Mechanical Designer

Design on your terms with expert applications that cover the end-to-end mechanical design process

The impact of modern mechanical design software on engineers and designers

Before the introduction of modern mechanical design software, engineers and designers were required to produce technical drawings by hand. This process took huge amounts of time and considerable skill. Making changes to a design meant that the technical sketches would have to be redrawn from scratch.

Mechanical design software has replaced the need for manual drawing. Instead, engineers and designers can use technology to develop and test new ideas without having to waste time and resources.

Professional mechanical engineers and machine designers throughout the world use sophisticated drafting and design solutions from Dassault Systèmes. For more than four decades Dassault Systèmes has been the industry leader in innovative CAD mechanical engineering software.

The different types of mechanical design software

In order to develop the very best product that they can, an engineering design team will require different types of drafting and design technology.

Browse all the Dassault Systèmes store applications

We feature in our store some of our best software to design, collaborate and innovate throughout the entire product lifecycle.

Content related to mechanical design software

What are the benefits of using mechanical design software?

2D and 3D mechanical design software enable designers and engineers to create complex, highly detailed technical drawings and models. These drawings and models are an integral part of the product design process.

Tests and iterations on new designs

Using mechanical design software materials, components, and processes can be designed, tested, and modified without the need to continuously redraw designs or build physical prototypes. Engineers and designers can take elements of previous designs and incorporate them into newer versions. They can more fully analyze their designs to identify weak points or build flaws.

Real-world simulation and cost savy processes

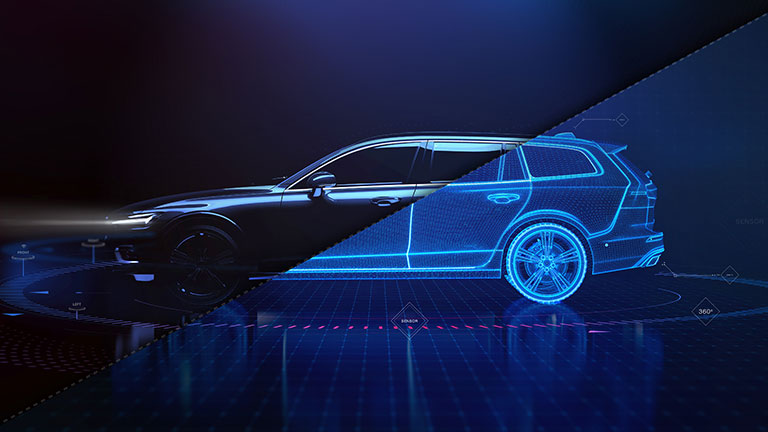

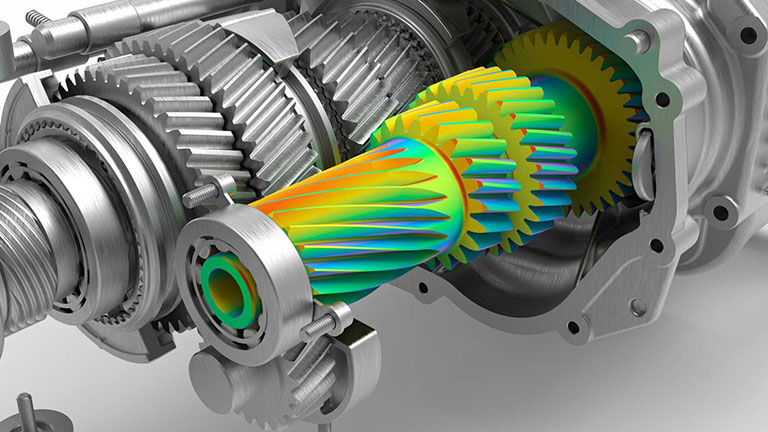

3D CAD models are often used for digital prototyping during product development. In this process, a digital environment can simulate real-world effects on a 3D model of a product, component, or machine. The results of these simulations provide data that can be then used to extend the product lifecycle, reduce the number of resources and materials used in manufacturing, streamline the production process, and reduce time to market.

What is the difference between CAD and CAE?

- CAD

- CAE

CAD is the acronym for computer aided design and refers to software that is used to create 2D technical drawings or 3D models. When engineers and designers talk about the CAD process, they are most often referring to the practice of designing a product, machine, or component. In other words, the act of developing an idea for a product or machine and then creating a schematic that shows how it could be built.

CAE stands for computer aided engineering. In industry terms, CAE refers to the process of analyzing and testing the digital representation of a product, component, or machine. The CAE process uses 3D parametric modeling technology to simulate how parts and materials interact with each other and environmental stresses.

What does the future hold for mechanical design softwares?

In the coming years, we can expect that mechanical design software will evolve to incorporate these 4 technological advances below. Mechanical engineers and designers will find that CAD programs will become more automated, data will be increasingly stored and shared off-premises, and new manufacturing techniques will further streamline the product design process.

Artificial intelligence

Advances in artificial intelligence (AI) and robotics are sure to have a huge impact on the field of mechanical engineering. As AI and robotics become more sophisticated, many design and manufacturing tasks will become automated.

Working from anywhere

Cloud based software solutions are rapidly becoming the norm for businesses and organizations. The cloud facilitates more agile product development processes as it allows team members in multiple locations across the globe to seamlessly work together on a project in real time.

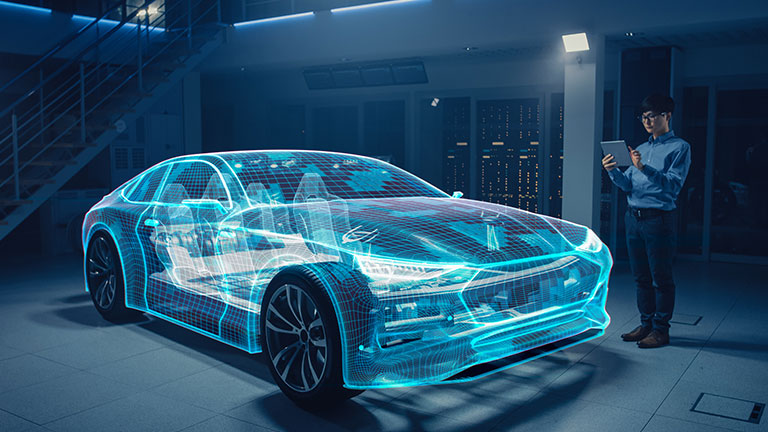

Virtual twin technology

Once only found in highly specialized sectors, virtual twin technology is now being used by a variety of industries. There are many exciting possibilities for the use of virtual twin technology in terms of product prototyping.

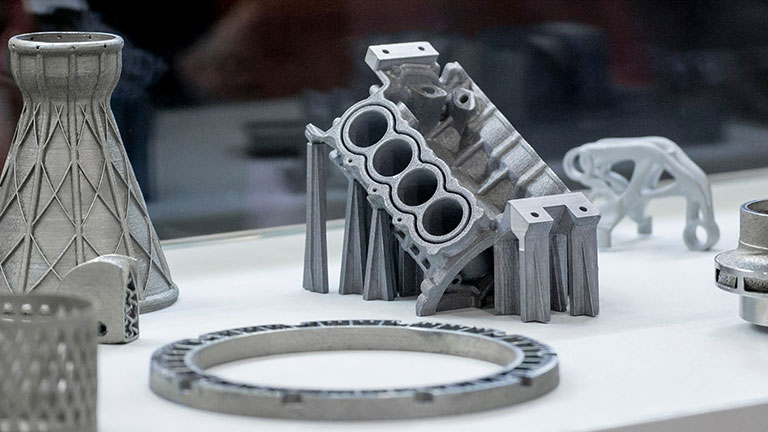

Additive manufacturing

Additive manufacturing is often referred to as 3D printing. While still very much in the development stage, additive manufacturing has the potential to revolutionize the way products are developed and produced. As 3D printing technology becomes more economical and efficient, designers will be able to reduce production waste, cut transportation costs, and allow for greater consumer customization of products.

Explore Dassault Systèmes solutions

Discover the powerful browser-based modeling solutions from Dassault Systèmes. You can design whatever you wish, wherever you are with 3DEXPERIENCE.

Connecting data & people to foster innovation

The 3DEXPERIENCE platform on the cloud gives you access to a various set of applications that allow you to design, simulate, inform and collaborate on a project.

Enabling better product design with mechanical CAD software

Taking a product from the ideation stage through to manufacturing can be a long process that requires creativity and dedication. Using mechanical design software allows engineers and designers to explore ideas and test various materials, structures, combinations, and components until they arrive at the optimum possible result.

As the world searches for ways to overcome the challenges posed by global warming, mechanical design software is enabling us to develop more sustainable, more energy-efficient, and more environmentally friendly products.

Using the advanced 3D modeling capabilities of CAD mechanical engineering software eliminates the need for physical prototypes, can reduce waste during the manufacturing process, and facilitates innovations in design.

Discover Dassault Systèmes unique solutions for mechanical design

Ever since the ground-breaking CATIA was first released in 1982, Dassault Systèmes has been setting the standard for CAD design programs.

Short for Computer Aided Three-Dimensional Interactive Application, CATIA is now in its sixth version. CATIA has been expanded to include a suite of programs designed to meet the needs of both experienced and entry-level designers and engineers.

- CATIA Sheet Metal Designer

- CATIA Mechanical Designer

CATIA Sheet Metal Designer

Dynamic, highly adaptable entry-level mechanical design software that is ideal for a wide range of industrial applications. Aimed at entry-level users, CATIA Sheet Metal Designer is an ideal program for students, sheet and mechanical designers, product developers, and engineers. This program can be used to design solid and surface geometry for any type of mechanical project. Complex sheet metal parts can be visualized in 2D and 3D to ensure easy fabrication.

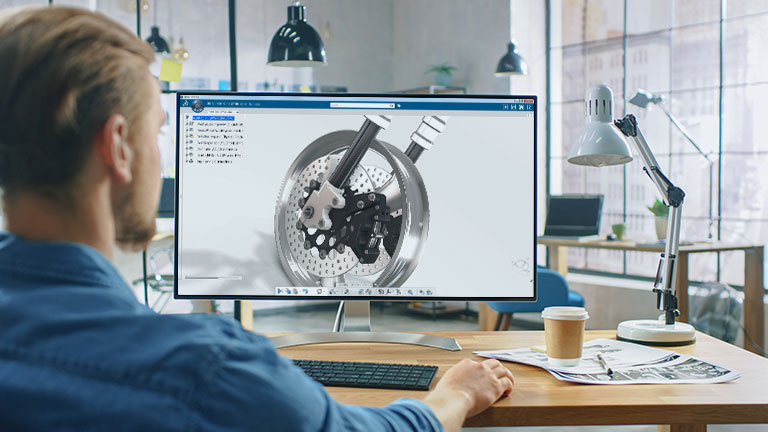

CATIA Mechanical Designer

An advanced mechanical design solution used for various highly complex aeronautical and industrial applications. CATIA Mechanical Designer provides users with unmatched scalability and flexibility. Its highly accurate and reliable 3D geometry can support large assemblies with ease, including full Model Base Definition for Product Manufacturing Information. With CATIA Mechanical Designer, mechanical designs can be enhanced with sophisticated and complex shapes, time to market can be minimized, and designers can explore concepts to develop more innovative products.

What is the best mechanical CAD software?

Ascertaining what is the best and most used mechanical CAD design software in a global sense is not an easy proposition. CAD mechanical design software is used by a huge variety of industry sectors, for many different purposes. Often, a company may use a combination of programs during its product development processes.

However, some CAD mechanical design programs stand out as being preferred by professionals over other types of software.

SOLIDWORKS

SOLIDWORKS from Dassault Systèmes has long been popular with mechanical designers in the aerospace and automotive sectors. SOLIDWORKS is also the preferred CAD solution for consumer product design, manufacturing, and the healthcare sector.

More than 230,000 companies in 80 countries are estimated to use SOLIDWORKS. Mechanical designers and engineers often find that employers are actively seeking to recruit people who have extensive knowledge of SOLIDWORKS.

CATIA

CATIA has been recognized for decades as one of the most innovative mechanical design programs on the market. This incredibly versatile 3D design software is widely used for CAD, CAE, CAM, and Product Lifecycle Management (PLM) solutions.

With its extremely powerful 3D modeling capabilities, CATIA has been used by such industry titans as Boeing and Frank Gehry. CATIA enables professional designers and engineers to develop sophisticated models that allow for enhanced development and testing of new products and machinery.

AutoCAD

First released in 1982, AutoCAD is perhaps the best-known 2D and 3D CAD mechanical design program. AutoCAD is widely used in the construction industry and for architectural and manufacturing design.

While AutoCAD can produce precision 2D or 3D designs at any scale, it is often criticized for its poor line editing capabilities, lack of parametric modeling, and limited compatibility with other file formats.

Fusion 360

One of the newer players in CAD mechanical engineering design, Fusion 360 was released in 2013. Designed to be a full-service collaborative CAM and CAD software, Fusion 360 is cloud-based and provides users with a good set of 3D tools with parametric modeling, surface modeling, freeform, and mesh modeling capabilities.

Simple to use for experienced CAD operators and affordable Fusion 360 is primarily designed for mechanical engineering purposes and is favored by students and hobbyists. However, the limited capabilities and functions of Fusion 360 make it unsuitable for large complex designs.

Why choose Dassault Systèmes for your mechanical design software needs?

40 years of experience

Dassault Systèmes is providing mechanical engineers and designers since 1987 with the tools they need to discover better ways of developing and producing products.

Our aim is to transform the design, simulation, manufacturing, marketing, and use of products and services. In conjunction with talented mechanical designers and engineers the world over, we continue to strive to surpass expectations and go beyond the limits of what is thought to be possible. Our range of CAD mechanical design software provides us with the tools to reach our goals and go further than ever before.

The power of the 3DEXPERIENCE

To develop the products of the future, engineers and designers require robust, flexible, and reliable mechanical CAD software.

All our mechanical design software are available throught the 3DEXPERIENCE wich is a cloud-based platform where you can collaborate on designs with team members and stakeholders at any time, wherever you or your team are located.