Develop Agile Technology & Services Portfolio

Insights from Safran

Frederic Vetil

Vice President Manufacturing 4.0 Safran Group

Enhancing Supply Chain Agility and Resilience

Driving the performance and agility of the supply chain and Manufacturing Operations to handle the necessary flexibility and resilience in the uncertain economic times is critical.

Indeed, the financial impact from the pandemic and supply chain crises has required companies in the aerospace and defense industry to redefine their competitive strategy within their traditional business and be more disruptive in new target domains and services.

Challenges and Opportunities

The current need for innovation and sustainability, and the unique challenges presented by global events have put lots of pressures on the aerospace and defense industry, which can be seen as opportunities, with companies making a shift towards more agile business models to remain competitive.

New competitive aircraft and system technologies have to be developed faster, have to be produced smarter and more efficiently to enable rapid market introduction capturing competitive market share and establishing customer trust. The engineering teams are faced with the opportunity to better leverage intelligent data from manufacturing operations, aircraft in service and the entire supply chain value network to set the new pace and strategy. Collaboration and data driven engineering aircraft development, production and service are key enablers to leverage the undisputed need for change. Suppliers will have to demonstrate a higher level of agility, increased digitalization and a much lower risk profile to deliver on time and with first time quality.

Discover How Dassault Systèmes Enables Agility in Aerospace and Defense by Introducing New Technologies & Services While Lowering Costs and Risks

Role of Agile Technologies in Aerospace and Defense Industry

With the high degree of variability of market demand and the increased international competitive pressure on price, developing agile technologies in aerospace and defense industry is critical.

The same digital continuity will reach out into the disconnected domain of aircraft and fleets in service for maintenance, repair and overhaul. The pandemic illustrated the responsibility of OEMs and operators to be able to react quickly on environmental impacts, with quick and reliable solutions and more flexibility within fleet operations.

Leveraging a collaborative and big data approach by connecting the real aircraft and systems in service with the virtual aircraft and system design and manufacturing is essential to drive the continuous, rapid and first time quality innovation. This is needed to stay competitive and the reduce exposure to the impacts of the current and future crises. Including the data intelligence approach into product development, manufacturing and aircraft in service processes, enables the predictability, machine learning and efficiency to understand what is required to innovate, how it has to be better engineered, most efficiently produced and maintained throughout the life of the aircraft and system.

Increase portfolio competitiveness by introducing new agile framework:

Reduce response time and cost through improved inventory and personnel management

Improve “up-time” with fewer unscheduled maintenance through predictive analytics

Strengthen quality maintenance through reduction of “No Fault Found” removals and incorrect spares

Agile Methodology Benefits in A&D

Agile technologies will result in faster, smarter, and more efficient development and production processes. It will enable to keep pace of innovation while driving costs down, develop Flight Modularity and accelerate the Journey to net Zero for the air transport. critical in commercial aviation. Also, with the high degree of variability of market demand, the increased international competitive pressure on price, the higher complexity of products, and the evolving competitive ecosystem: developing turnkey capabilities from design to certification will be key for aerospace & defense suppliers. For the defense segment, the results will be to improve responsiveness to changing threats, increase systems availability and personnel readiness, manage systems complexity and requirement for joint forces interoperability.

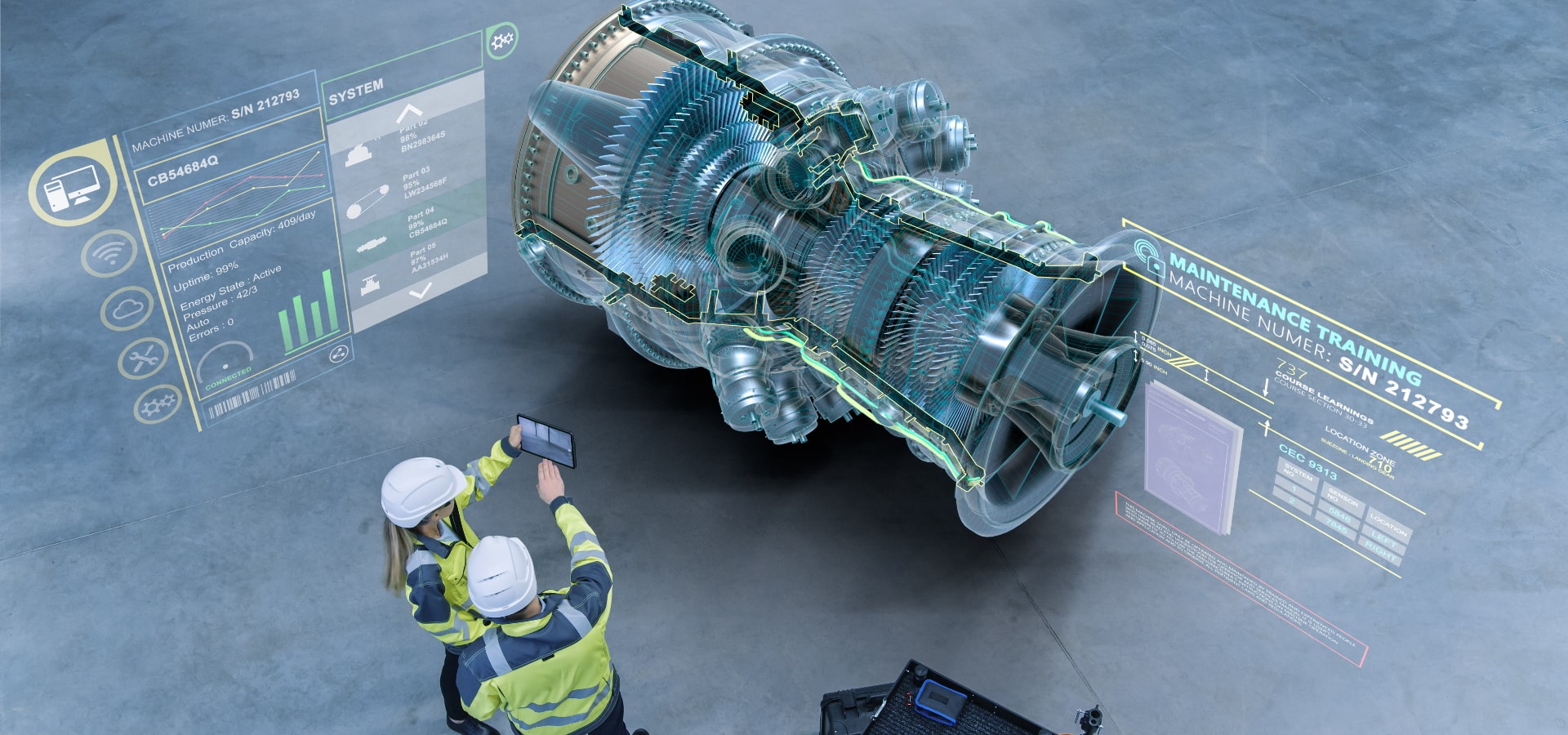

Virtual Twin Experience to Reshape Business Execution

The 3DEXPERIENCE® platform provides the digital twin continuity needed to aggregate data to make informed decisions, simulate potential issues, perform out of cycle development, certification on demand, and data driven services to perform a predictive maintenance strategy to improve “up-time.”

When combining the efficiency and flexibility of the platform with deep technical capabilities and tools to accomplished targeted tasks, such as using virtual testing for means of compliance, OnePart & additive manufacturing to minimize inventories, or serialized virtual twin for operations, companies can proactively reshape their business models for today and the future.

FAQ

The agile approach in aerospace adapts flexible, collaborative methods from software development to streamline project management, speed up development, and improve adaptability in the aerospace industry.

In engineering, "agile" results in flexibility, collaboration, and iterative development. It involves breaking down projects into smaller, manageable tasks, continuously gathering feedback, and adapting to changes quickly. Agile methodologies prioritize customer satisfaction, teamwork, and the ability to respond to evolving requirements efficiently.

Explore our Industry Solution Experiences

Learn how to deliver on economic, environmental and social promises: