What's Next in PLM? with Steven Atherton of REE Automotive

Discover PLM applications engineer Steven Atherton’s insights into how he uses PLM for EV development and manufacturing at REE Automotive.

Designing Impactful Innovation podcast - episode 14

REE Automotive develops and manufactures electric platforms and vehicles and is known for its flat, scalable and modular EV platforms.

Steven Atherton, PLM applications engineer at REE Automotive, shares his experience with product lifecycle management (PLM) in transportation with Arvind Krishnan, industry analyst at Lifecycle Insights. Tune in to learn about PLM trends and challenges in the industry, the benefits of cloud-based PLM and what’s next for REE Automotive.

Meet our speakers

We don't have to worry about server rooms and keeping everything nice and cool. In this day and age, we just rely on the cloud. We don't have to worry about updates, we don't have to worry about security.

You can follow the "Designing Impactful Innovation" podcast on Apple podcasts, Spotify, Deezer, YouTube or by RSS.

Stay tuned!

Read the transcript

Clara: Hello and welcome to the Designing Impactful Innovation Podcast. I'm Clara, your host, and today we're talking about product lifecycle management trends and challenges in the automotive industry. Let's listen to Steven Atherton, PLM applications engineer at REE Automotive, and Arvind Krishnan, industry analyst at Lifecycle Insights.

Arvind: Hello and welcome to today's podcast. I’m Arvind Krishnan, a senior industry analyst with Lifecycle Insights. Today, I have the pleasure of talking to Mr. Steven Atherton from REE Automotive. Steven is the PLM applications engineer at REE Automotive. Steven, thank you for taking the time to chat with me today.

Steven: Absolutely. It's a pleasure to be with you today.

Steven: Yes, I've been with REE for nearly two years now. I'm the PLM applications engineer, as you said, and I look after 3DEXPERIENCE within the company. I've got a mechanical background and engineering background, but my passion is for bill of material and change management. And it's a great combination to use the PLM tool from Dassault. So it's great for me.

Part numbers and structured bill of materials are my life, I’m a real sad person when it comes to that! This is where I’ve focused my working life for the last 15 years or so, using a multitude of systems and software applications. And I've recently become an ENOVIA champion, which is really, really exciting.

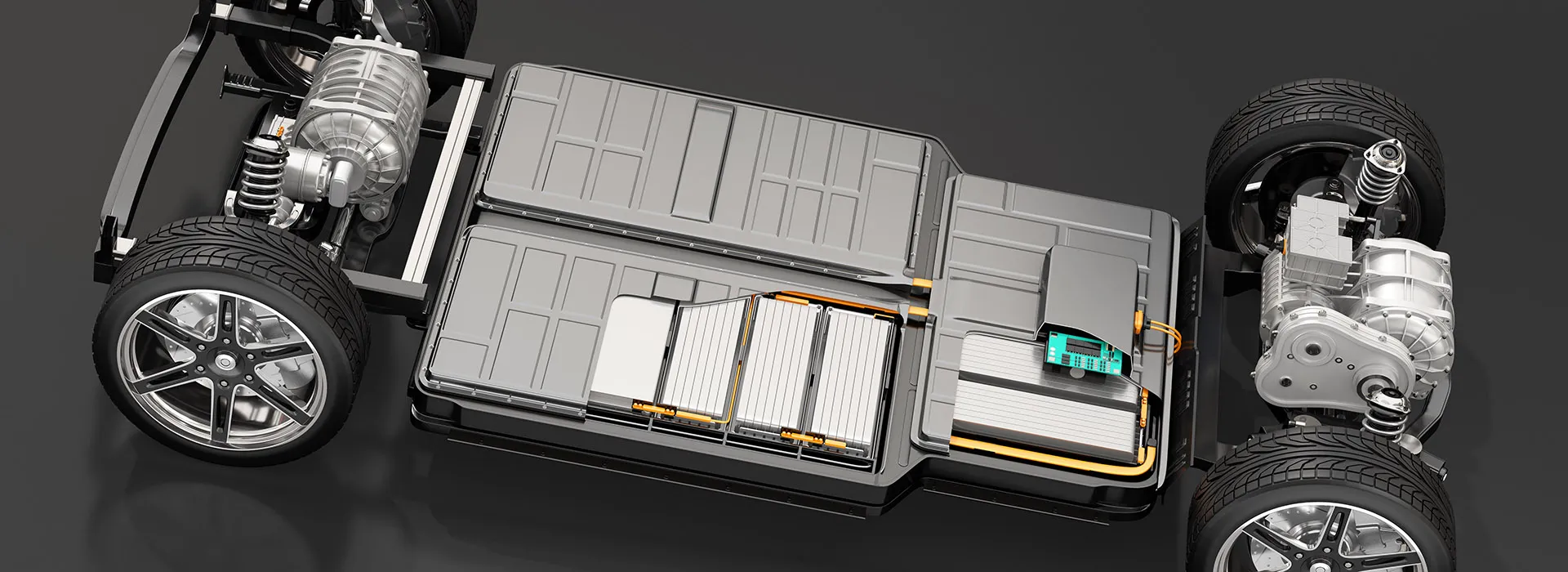

A bit about REE! REE is an automotive technology company working to build the most efficient commercial electric vehicle to market. Our core technology, the REEcorner, integrates critical vehicle components like steering, braking, suspension, powertrain control, all in one single compact module, which is located between the chassis and the wheels, and is individually controlled by wire technology, x-by-wire technology.

So with this technology, we are able to create a full flatbed chassis modular EV platform which allows more space for cargo, batteries, people, as well as an ergonomic advantage from a very, very low floor. And we’re currently focusing on a Class 3 to 5 commercial vehicle, which is being built to earth urban environments.

We're an agile team, product-focused, adaptable, streamlined processes with a very, very focused reporting structure. Our overarching mission is to be the cornerstone of zero-emission electric and autonomous vehicles. We aim to empower global companies like OEMs, delivery and logistics fleets, dealers, e-commerce retailers, new mobility players to build any size of vehicle, any shape, any electrics for an autonomous vehicle. That's what our mission is, that's where we're heading.

Arvind: Excellent Steven. Thank you for giving a good tour of REE Automotive and your role there.

Steven: With all startups, having a clean sheet of paper always comes with challenges, but there's opportunities too. Without having the legacy of outdated processes and systems, a fresh approach can be...just mind boggling, and it can come with a myriad of benefits too, you know? I’m based in the UK, in the engineering sense, which also houses our prototype and pilot build facilities.

And by the very nature of its location – the proximity to one of Europe's automotive hubs, the Midlands is the Detroit of the UK – where resources are in our demand. So, those challenges also come with benefits.

Steven: So the choice of CATIA V6 – so PLM through the Dassault system – was not an accident. It's the weapon of choice for most of the car industry in the UK and our central location gives us access to a wide range of skill sets that can help us with our growth with the benefit of a really exciting product. So we've got the benefit of an exciting product and a pool of superb resource in the area. So that really helps. Our challenges come with that massive win.

Arvind: I want to dwell on the topic of collaboration. Certainly building a complex system like what you do at REE Automotive involves a lot of collaboration between different players. So let's spend a little bit of time on that. You mentioned that collaboration and having access to the right talent is probably one of the challenges and an opportunity for your company.

As a new organization, it's certainly true that your engineers work closely amongst each other, but also with some external stakeholders. They could be your customers, partners, suppliers, etc... You know, in one of the earlier podcasts, I had the pleasure of talking with Stéphane Déclée, he is the CEO of ENOVIA, and Stéphane mentioned that collaboration is one of the key enablers for innovation.

Steven: Absolutely. As a multi-location company without the unlimited supply of resource and an extensive IT infrastructure, we reutilize the cloud situation wherever possible. Working on the cloud, the data is always live and the layout with the latest information – when our CAD team progresses the design, sometimes offshore, the engineering leads around the globe can review that data in real time, have their input, have their feedback, and it's just like having the guy sat next to you.

When the CAD guy sneezes, we can pass him a virtual tissue. It's so live, and that's the benefit of the cloud. We don't have to worry about server rooms and keeping everything nice and cool. In this day and age, we just rely on the cloud. We don't have to worry about updates, we don't have to worry about security. That has been really an issue for us. So we're very keen.

The cloud has given us a benefit to work with, not only our internal suppliers, who are in multiple locations within the UK – different parts of the office, we can share data. We don't have to walk very far to speak to the data, it's great! We can share stuff with our offshore resource, which we use quite a lot, with our management team in various locations, we can show them the data, we can show them the product, we can show them where we're up to, we can share resources. It's just fabulous. It's just a great, great tool for us.

And it's live, it's not “Ok so we've got a meeting today, can we upload some data?” It's just live, I can see it, I can see what people are up to all the time, which is fabulous, great for our manufacturing team as well.

Arvind: Steven, you articulated some of the key benefits of a cloud solution. And maybe now let me just talk a bit about the research that we at Lifecycle Insights did a while ago, and we found something very similar to what you articulated as the advantages of a cloud solution. You talked about being live all the time.

Now, our research said that three in four of the companies, three out of four, or 75% of the companies, said that in five years from now, their company will be using either an exclusive cloud solution or a combination of a cloud and hybrid solution for PLM and obvious reasons that you correctly articulated could be the reason why companies are moving here.

If you would like to know more information about this research study and the results, you can find them on the Dassault Systèmes website, 3ds.com/cloud.

Let us change directions, Steven, and talk about the cloud. Cloud-based PLM solutions are making great progress.

Arvind: Do you feel that they are safe and they can protect your intellectual property? Considering some of the exciting and new developments that you are embarking on at REE Automotive, what are your thoughts here?

Steven: Yes, cyber security is a big, big point within REE. We've got some great technology which we want to keep to ourselves for sure. So, when we made the decision to go to the PLM system through Dassault, we had the choice of either on-premise or on cloud and our IT team did a very, very intensive trawl of the data and check in and gave it a little mini attack to make sure that it was all good for us.

And it came back with a very, very clean bill of health. So regardless of whether we were on premise or on cloud, from a cyber security point of view, we're in great shape. And from a cyber security point of view, I would always go into the cloud room because the data is up to date all the time.

The firewalls, and all the infrastructure that protects it is up to date. You know, we don't have to do an upgrade every weekend to keep the software room to date. It's all done remotely. So that's a real benefit for us. If we went on premise, especially with our multiple locations, we would have a nightmare of our own. So putting three decks through the cloud is a definite win for us.

Arvind: Yeah. You talked about the go/no go decisions. I'm wondering – probably a lot of people having a similar hack in other companies, but actually talking about cybersecurity and the safety of cloud being an important decision-making component in their decision to go towards the cloud. And thank you for going over some of the procedures that your IT team went over before selecting a cloud-based solution.

Now, Steven, you've been a PLM advocate and a person in the PLM industry for a long, long time. And we all know that PLM is intimidating for small companies. You know, companies think that they need an elaborate IT system, they need people to manage PLM. In other words, they are having to make a trade off between managing the PLM versus the benefits they get out of the PLM. And this has been a difficult journey for a lot of small companies.

Steven: So, lessons learned, a hindsight: a wonderful thing in all these situations like that, is if you're embarking on the PLM journey, people get this preconception that PLM is all about the CAD, which it’s absolutely not. And we can talk about that surely, but regards our side, the journey at REE – having a clear direction, so you know what the tool is going to do, what you want, where you want to end up, is a very key enabler to get success using a PLM system.

It is quite intimidating at the start for sure. But if you keep it simple – so you know where you want to go, you know what you want to end up doing, you're not going to save the world overnight and produce something that is hundred percent perfect from a system point of view.

Keep it simple. Start with a process that can be developed, that you can build foundations and let the system grow with you. So having that clear focus at the very, very start of the project, understanding where you’re going, understanding what you need, what the end goal is, is really, really key.

And the one thing that we did from the very start of the process is, we kept everything simple. Simple part number, using industry-standard best-in-class processes, but simple, rather than making very complicated processes that people bring in from OEMs within the area. Just keep it simple, keep it focused, solid foundations that you can build as the project grows.

And we never let the design of the product be limited by our processes. The lead was always the product. So we never got hung up on our processes and the systems and our software. We didn't let that hinder the design in any shape or form, and I think that was a real key win for us. But knowing where you’re going at the start is a big thing.

The Dassault portfolio of products is like a sweetshop. You can walk in there, there are so many tools that you can use, you can buy, you can work with, and half of them probably are no benefit to everybody. So keep it simple. Start with what you know, build the product, build the process, build the platform and add as you need. And I think that's where we’re winning over now for sure.

Arvind: This is indeed sound advice to someone who is looking to embark on the PLM journey. I heard “keep it simple” so many times and it looks like such an important piece of being successful in the PLM journey. So what you advocated is to keep things simple and a crawl, walk, run approach to PLM.

We are coming towards the end of our discussion today but before you leave, Steven, I want to touch upon one final topic that is dear to you and your company, REE Automotive.

Steven: So, for REE, PLM is not just about managing the 3D data, it's about that bigger picture: giving everyone, regardless of their role or location, access to all the good information. One source of truth sounds cheesy, but it’s so, so true. People get hung up on PLM as a CAD tool. It could not be further from reality.

The clue is there in the title: product lifecycle management. From BOM, CAD, change management, issue management, eBOM into mBOM, the benefits are endless. We are now just heading towards certification so it's such an exciting time. And in terms of Dassault and the PLM route, we're just about to kick off Material Compliance Manager, which is managing our IMDS, which is taking us closer to that ramp up into production, which is full steam ahead at the moment. Such exciting times within REE.

Arvind: Thank you for sharing these future projects with us, Steven. Actually that concludes the end of this podcast. So Steven, thank you very much for your time today and all the insights that you shared with us.

Steven: You're very welcome. Thank you so much for your time.

Clara: Thank you for listening to Designing Impactful Innovation. To find out more, go to 3ds.com/cloud. Don't forget to subscribe for more insights and stories from our guest experts!

Ready to learn more?

See how the 3DEXPERIENCE platform on the cloud can transform your business. Fill out the form to get in touch with our experts.