Refining Battery Integration and Development

Overcome engineering challenges to accelerate innovation in battery systems

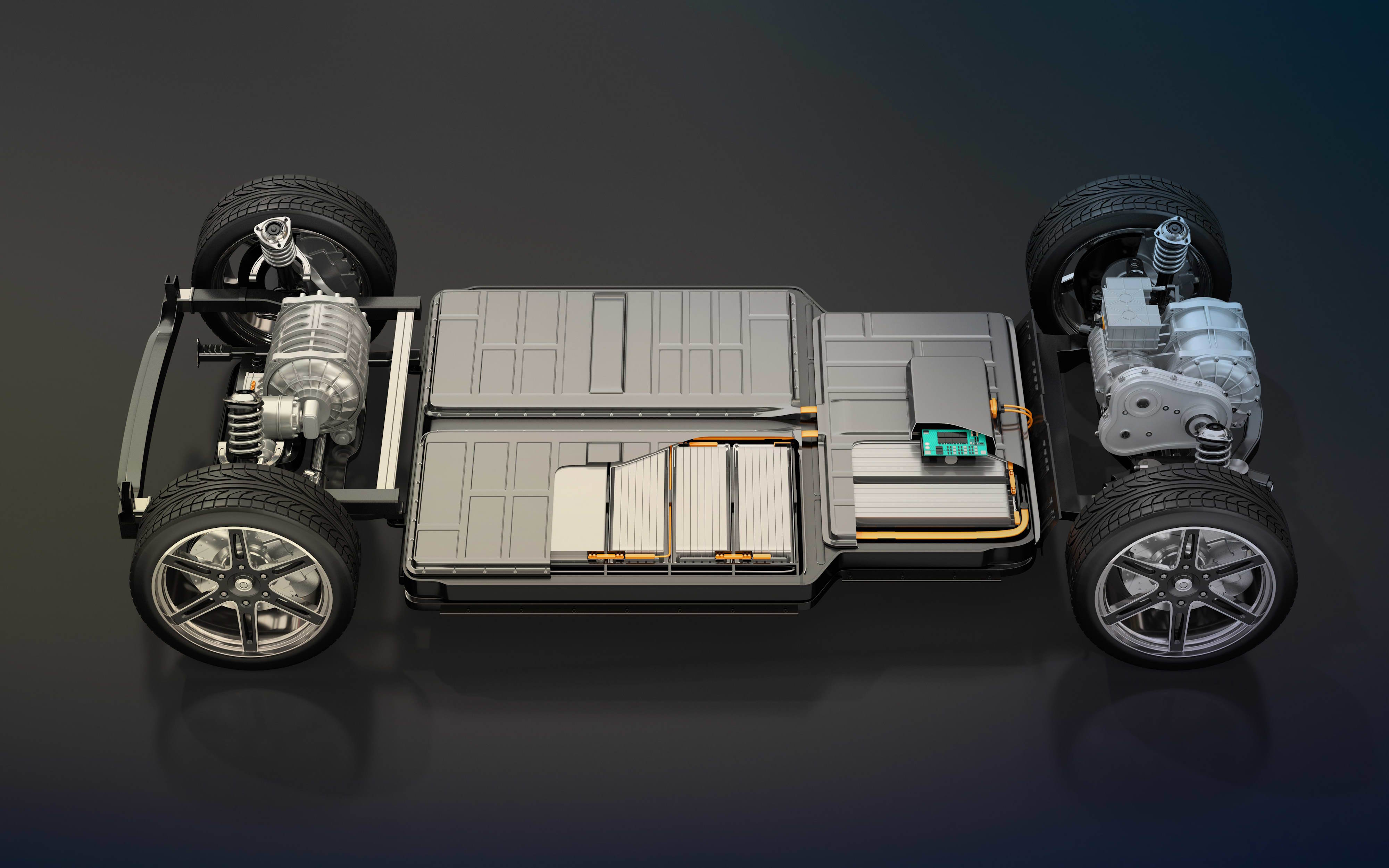

Challenges in Battery Integration and Development

As industries increasingly embrace electrification, the demand for efficient and powerful battery storage systems continues to surge, driven by the reliance on advanced industrial battery technology & systems. This expanding market presents developers with complex engineering challenges. Balancing requirements like peak power draw, extended lifespans, and safety across the entire life cycle necessitates a diverse team of experts.

Coordinating efforts between stakeholders in battery integration can be problematic. Using generic tools like shared documents often leads to oversights and delays, hampering decision-making and increasing project costs.

Innovative solutions are essential to streamline battery integration processes and ensure success in this evolving landscape.

The tools and methods that battery integration engineers have traditionally used to design their products are simply not capable of overcoming the complex engineering challenges that keep costs high and make rapid innovation so challenging.

Key Trade-offs in Battery Pack Selection for Drones and EVs

When selecting battery packs for drones and electric vehicles (EVs), it’s essential to consider several critical trade-offs to optimize performance, cost, and safety. The 3DEXPERIENCE platform on the cloud can help with making informed decisions regarding these trade-offs by providing advanced modeling, simulation, and collaboration tools. Here are the primary factors to evaluate:

Energy Density vs. Weight

- Energy Density: Maximizes range and operational time.

- Weight: Heavier batteries impact flight time and efficiency.

Power Density vs. Energy Density

- Power Density: Essential for quick energy delivery and acceleration.

- Energy Density: Extends range but can compromise power output.

Cost vs. Performance

- Cost: Higher performance comes with higher costs.

- Performance: Enhances range, power, and efficiency but increases price.

Safety vs. Energy Capacity

- Safety: Safer chemistries have lower energy densities.

- Energy Capacity: More energy can mean higher safety risks.

Charging Speed vs. Battery Lifespan

- Charging Speed: Fast charging is convenient but reduces lifespan.

- Battery Lifespan: Slower charging extends battery life.

Temperature Tolerance vs. Performance

- Temperature Tolerance: Reliable in various climates.

- Performance: Compromises may be needed for temperature range.

Capacity vs. Form Factor

- Capacity: Longer operational times but larger and heavier.

- Form Factor: Compact designs may offer less capacity.

Sustainability vs. Performance

- Sustainability: Environmentally friendly but may lower performance.

- Performance: High-performance materials pose environmental challenges.

Balancing these trade-offs requires a holistic approach, taking into account the specific requirements and user needs for drones and EVs. The 3DEXPERIENCE platform on the cloud offers comprehensive solutions to streamline this decision-making process, ensuring optimal outcomes for battery integration and development.

Optimizing Battery Integration

Effective collaboration practices are crucial for navigating performance, cost, and sustainability trade-offs during battery integration and design. Modern modeling and simulation solutions provide a superior approach, offering real-time visibility into design iterations. This enables confident decision-making based on the latest information, resolving issues before prototyping and testing, and reducing failures and rework.

- EV battery innovation

- Revolutionizing eVTOL battery innovation

Accelerate EV Battery Innovation

To achieve the required levels and pace of innovation to stand out in the market, accelerate EV adoption, and reduce costs while improving sustainability, EV manufacturers should consider the following recommendations:

- Evaluate the organization’s approach to EV battery technology development and assess available solutions for EV battery development, especially with regard to battery pack integration and design, to determine competitive weaknesses.

- Explore how digital engineering solutions can improve collaboration processes and outcomes.

- Determine how model-based design, simulation, and lifecycle assessment (LCA) solutions can improve battery design, performance, integration, and sustainability.

Revolutionizing eVTOL battery innovation

Are you facing intricate engineering challenges while integrating new battery cells into your drone or eVTOL designs? Do you aim to optimize drone/eVTOL range, acceleration, and overall performance? Achieving innovation demands precision and ingenuity in overcoming these complexities.

Unlock the secrets to mastering eVTOL battery development and integration to:

- Effectively navigate intricate engineering trade-offs.

- Optimize power and energy requirements for sustainable drones and eVTOLs.

- Enhance battery cell efficiency and safety.

- Accelerate innovation in drones and eVTOLs battery cell technology.

FAQ About Battery Technologies & Industry

Lithium-ion batteries are commonly used in most plug-in hybrids and all-electric vehicles. Energy storage systems, typically in the form of batteries, are crucial for the operation of all-electric vehicles, plug-in hybrid electric vehicles (PHEVs), and hybrid electric vehicles (HEVs).

| Battery Type | Common Uses | Characteristics |

| Alkaline Battery | Household items like remote controls, clocks, and flashlights. | Non-rechargeable, long shelf life, relatively inexpensive. |

| Lead-Acid Battery | Automotive batteries, backup power supplies, industrial applications. | Rechargeable, high power output, cost-effective, heavy, contain toxic materials. |

| Nickel-Cadmium (NiCd) Battery | Power tools, medical equipment, emergency lighting. | Rechargeable, robust, long cycle life, memory effect, contain toxic cadmium. |

| Nickel-Metal Hydride (NiMH) Battery | Consumer electronics, hybrid vehicles, rechargeable household batteries. | Rechargeable, higher capacity than NiCd, less prone to memory effect, shorter lifespan. |

| Lithium-Ion (Li-ion) Battery | Laptops, smartphones, electric vehicles, portable electronics. | Rechargeable, high energy density, lightweight, long lifespan, sensitive to high temperatures. |

| Lithium-Polymer (LiPo) Battery | Drones, RC vehicles, some portable electronics. | Rechargeable, flexible shapes, lightweight, high energy density, require careful handling. |

| Solid-State Battery | Emerging technology, potential uses in electric vehicles, portable electronics. | Rechargeable, higher energy density, safer, more stable than liquid electrolyte batteries, more expensive. |

| Zinc-Carbon Battery | Low-drain devices like remote controls, clocks, basic flashlights. | Non-rechargeable, inexpensive, low energy density. |

| Zinc-Air Battery | Hearing aids, medical devices, some large-scale energy storage. | Non-rechargeable, high energy density, activated by exposure to air. |

| Silver-Oxide Battery | Watches, calculators, small electronic devices. | Non-rechargeable, high energy density, stable voltage, more expensive. |

| Sodium-Sulfur Battery | Grid energy storage, large-scale power backup. | Rechargeable, high energy density, operate at high temperatures. |

| Flow Battery | Large-scale energy storage, renewable energy integration. | Rechargeable, scalable, long cycle life, complex, expensive. |

Lithium-ion batteries are widely used in most plug-in hybrids and all-electric vehicles due to their high energy density. These batteries are crucial for the operation of various electric vehicles:

- they serve as the sole power source in all-electric vehicles,

- work alongside internal combustion engines in plug-in hybrids (PHEVs),

- support engines by providing additional power in hybrid electric vehicles (HEVs).

This highlights their vital role in advancing sustainable transportation.

Recent advancements in lithium-ion battery technology are promising a bright future. AI-driven innovations are optimizing battery management systems, improving charging cycles, predicting maintenance needs, and preventing failures for better performance and safety. The development of solid-state batteries is increasing energy density and reducing overheating risks. Incorporating nanomaterials is enhancing electrode conductivity and durability, leading to faster charging and longer lifespans. These breakthroughs are making lithium-ion batteries more efficient, reliable, and safer for applications ranging from electric vehicles to consumer electronics and renewable energy storage.

Learn more about Integrated Battery Development Solutions

Ready to learn more?

See how the 3DEXPERIENCE platform on the cloud can transform your business. Fill out the form to get in touch with our experts.