Explore and Validate Design Alternatives with Performance Driven Generative Design

Automatically generate optimized conceptual parts from a functional specification at the push of a button.

Performance driven generative design allows you to explore and validate designs through simulation, make informed decisions on weight reduction and optimized performance. Generate shapes that could not have been imagined using conventional design methods.

Benefit from a newfound freedom to take advantage of flexible design processes while benefiting from the seamless alliance between design, simulation and manufacturing. No data is lost in translation, and speed and agility of design optimization and evaluation is multiplied - allowing you to create better products faster.

Even without simulation and optimization expertise, designers can set up and run generative design cycles themselves, creating lightweight components and achieve significant performance gains.

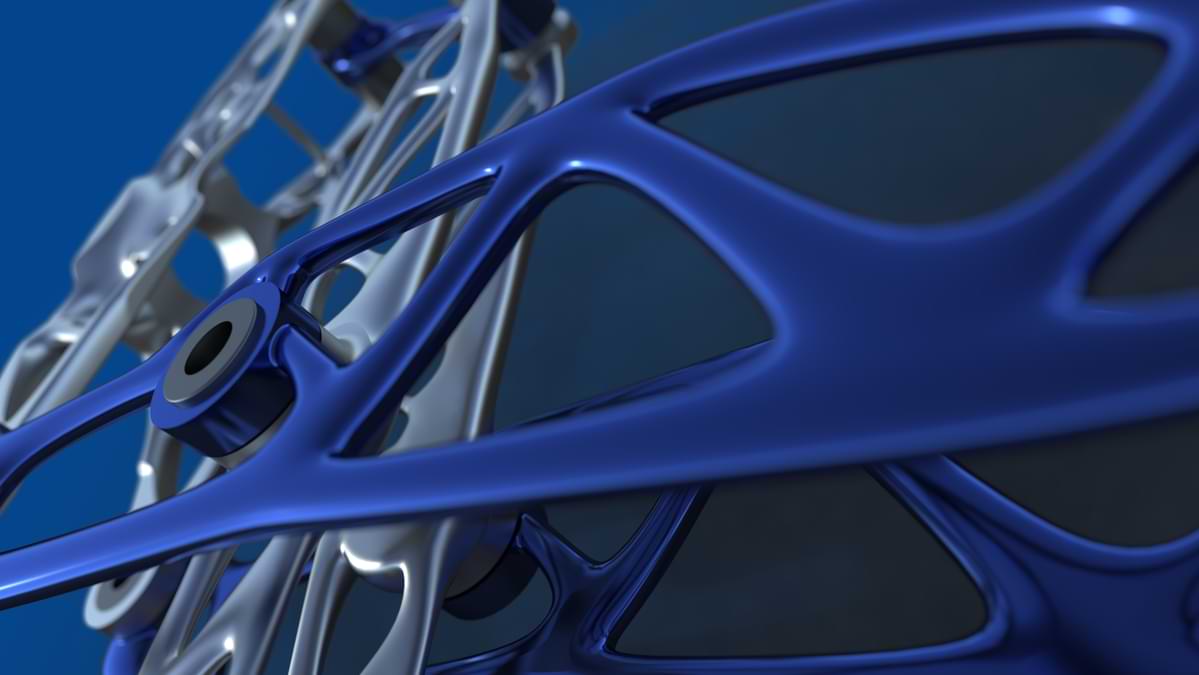

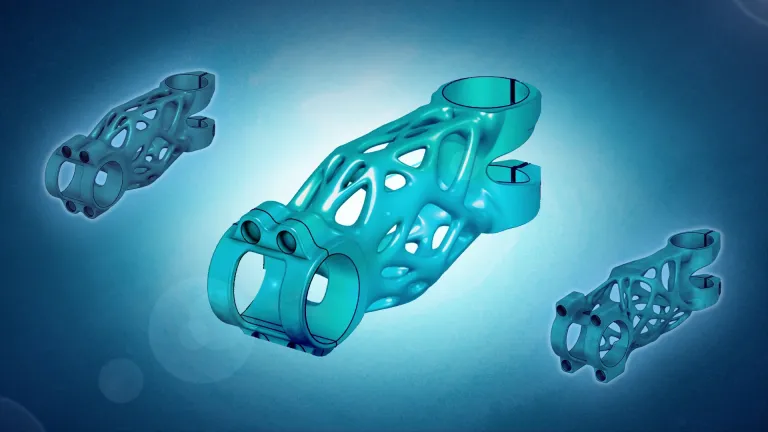

Function driven generative design

Function driven generative design allows designers to capture all functional specifications: geometrical inputs, but also analysis inputs, optimization target and constraints. The generative aspect comes from the modeling reduction in this process. Concept shapes are generated from a simple push button to obtain an exact representation, and we can easily validate the structural behavior of this concept.

With such a design study, designers can easily create, visualize, compare different variants and their resulting KPIs to perform a trade-off and select the best concept. This workflow is also based on the manufacturing constraints defined upfront, and handles Additive Manufacturing along with more traditional processes such as milling, cast and forge …

While moving on to detailed design, designers have at his disposal different sets of capabilities to assist him with the detailed modeling of the part, which can still easily be structurally validated before moving to manufacturing.

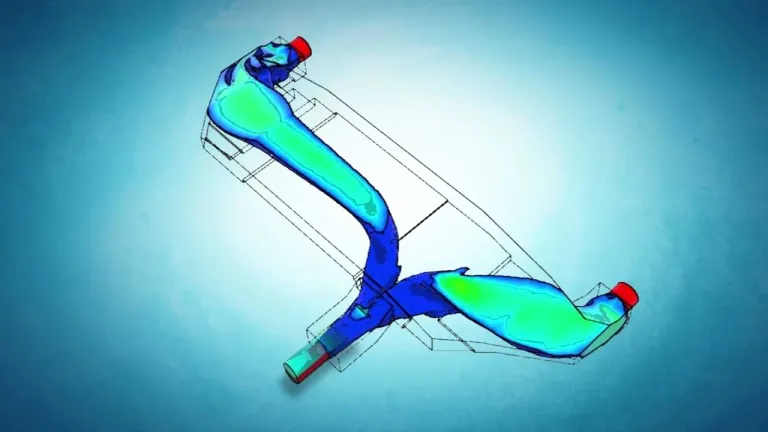

Fluid flow generative design

Fluid flow generative design allows designers to improve the efficiency of internal fluid systems by generating shapes that respect performance KPI targets, via a streamlined & intuitive workflow experience.

- Explore and generate shapes for internal fluid flows that minimize pressure drops and preserve the mass flow rate (HVAC, cabin comfort systems, etc.)

- Generate automatically flow-driven shapes, validated with an easily set-up Navier-Stokes CFD simulations

- Promote a seamless collaboration between Design and Simulation departments

The creator simply provides the design space and specifications and new concepts are generated. Then depending on the manufacturing process you selected to actually manufacture the part you can now adapt the shape of the part to comply with the constraints coming from the selected manufacturing process.

Performance driven generative design on the cloud

Automatically generate optimized conceptual parts from a functional specification at the push of a button