Integrated solution for manufacturing line design

Building lines that out perform the competition through improved customer experiences

In today's manufacturing market, the challenge for engineers, manufacturers, line builders and system integrators is to move efficiently from ideas to implementation. The aim is to take all steps possible to facilitate innovation and avoid unnecessary delays and rework. After all, time is money. To remain competitive, manufacturing businesses need to optimize everything from product architecture and engineering all the way through to installation and commissioning.

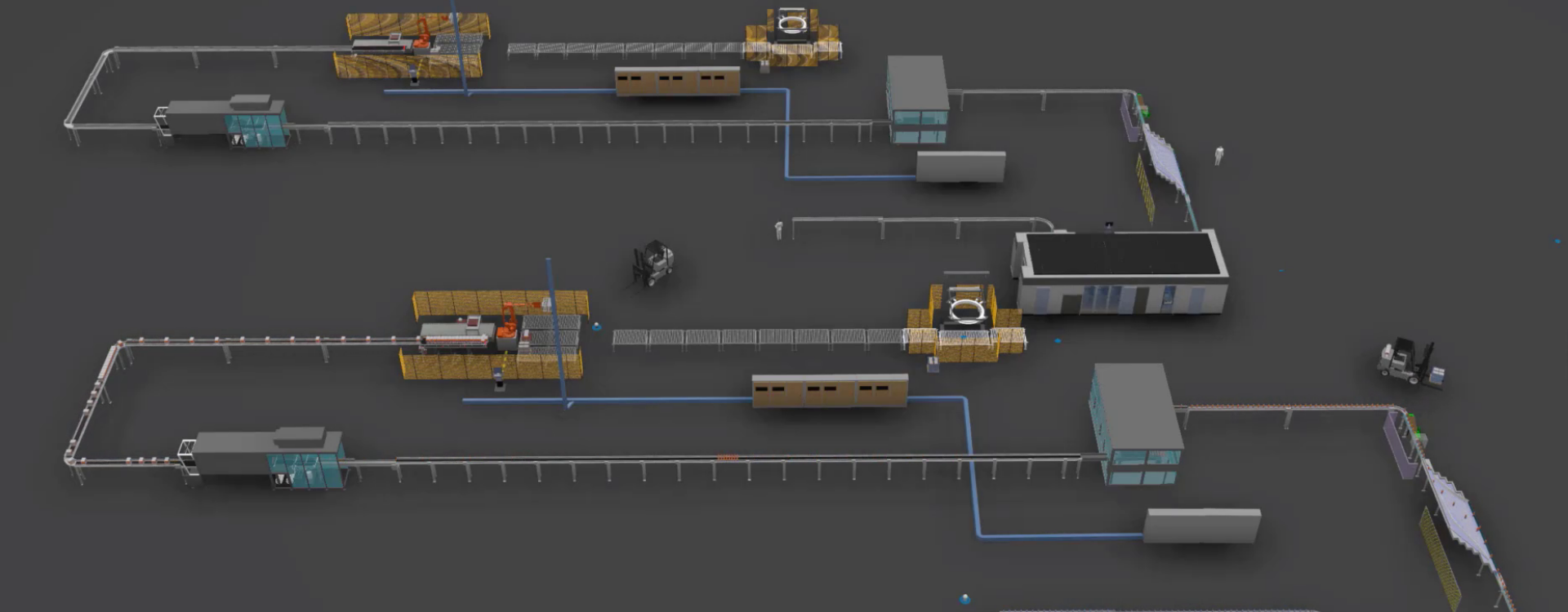

Manufacturers of any size can adopt new processes and systems that reduce design incompatibilities between sales and engineering. Using 3D technology in a single platform, OEM line manufacturers can demonstrate the final product design and performance in an immersive experience that raises the customer’s level of satisfaction

A solution for each step of the line building workflow

Benefits for manufacturers and line-builders

- Building a 3D representation of a production line and leveraging engineering data to simulate how the equipment will work will ensure a more efficient and accurate build and installation.

- Digital continuity with the 3DEXPERIENCE platform will ensure seamless management of data and eliminate incompatibilities between sales and engineering.

- Deliver an immersive customer experience using the virtual twin of the manufacturing line

- Improve win rate and tender accuracy, by using the 3D to facilitate the communication between the customer, the sales team and the engineering team.

- Save time from sales proposal layout to manufacturing design by ensuring the continuity between the inquiry-to-order, engineering and validation phases.

- Reduce drastically the commissioning time and cost thanks to a virtual validation of the line prior to the physical build.

Complete the journey to Industry 4.0 with Virtual Commissioning

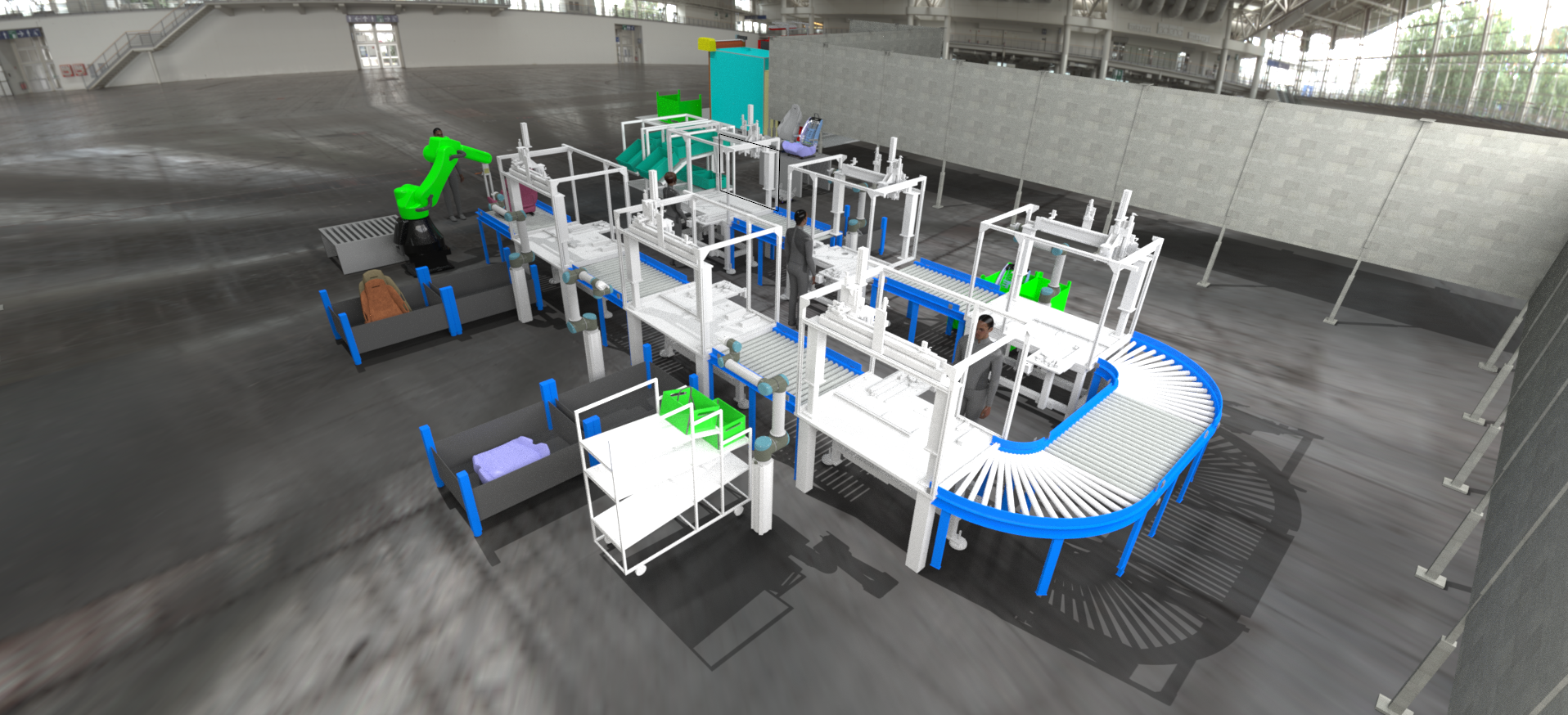

Manufacturers and line-builders are using the 3DEXPERIENCE Cloud platform to create a digital replica of their factory lines. This Virtual Twin gives them the ability to design, simulate and virtually test their manufacturing line before any physical element comes into play and will eventually allow them to speed up development, reduce risks and costs.

A great help when we know for example that line commissioning is responsible for up to 70% of project delays, often due to errors in the control process.

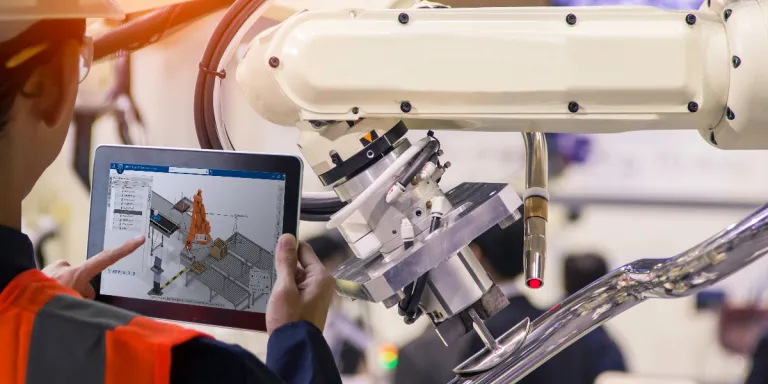

With virtual commissioning, you’ll be able to design, install or test control software with a virtual machine model before committing it to the real system, reducing the chances of unwanted errors.

Discover how the virtual commissioning can help you complete the journey to Industry 4.0. in this article.

Key to Optimizing the Manufacturing Line: Virtual Commissioning

Virtually simulate, commission, and validate to improve your production line.

Virtual Commissioning: anticipate and optimize your industrial performance

Discover how you can build better production lines with virtual commissioning.

How to Maximize Your OEE Score

Virtually simulate and validate manufacturing lines

Ready to learn more?

Contact us to learn more and see how the 3DEXPERIENCE platform can transform your business.