Virtual Twin Experience on the Cloud

Instantly gather valuable insight into the real-world performance of products and processes to improve operational resiliency, reduce costs and gaining in competitive advantage with cloud based manufacturing solutions.

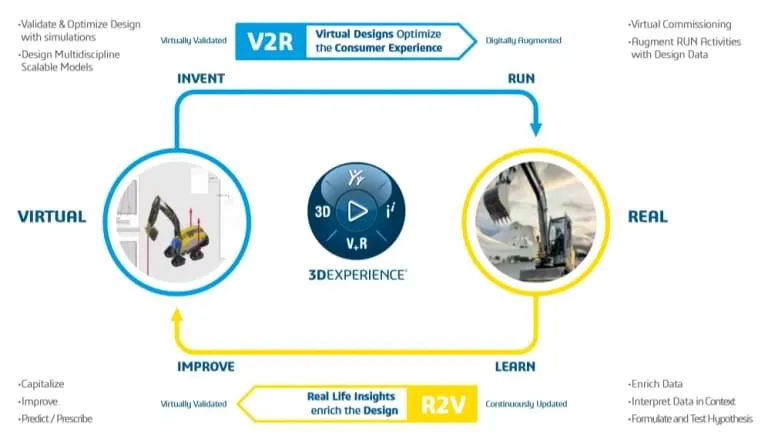

Benefit from the convergence of the virtual and real worlds

Virtual Twin Experience on the cloud is an executable virtual model of a physical system which brings in learning and experiences taken from the real world processes to update the digital twin model.

Achieving this closed-loop capability is the full realization of benefits to be gained from the convergence of the Virtual and Real Worlds

Improve Efficiency & Flexibility

Improve decision making

Reduce travel cost

Share best practices

Increase Operational Resiliency

Provide spatial context

Manage safe distancing

Re-optimise new workflows

Sustainable Innovation

Shorten time to market

Reduce time-to-simulate

Streamline workflows

Explore possibilities with the power of Manufacturing Virtual Twins

In today’s world, the manufacturing industry has grown to be global, dynamic and extremely competitive.

The time, effort and not to mention the cost of continuing to deliver high-quality products as well staying ahead of the competition can become too burdensome for manufacturers.

One way to get ahead is to implement a virtual twin – a virtual mirror of components in the manufacturing process. Virtual Twins allows companies to optimize their operations, build resilience, model, simulate and validate new manufacturing and operations processes. While avoiding costly and time-consuming physical implementation.

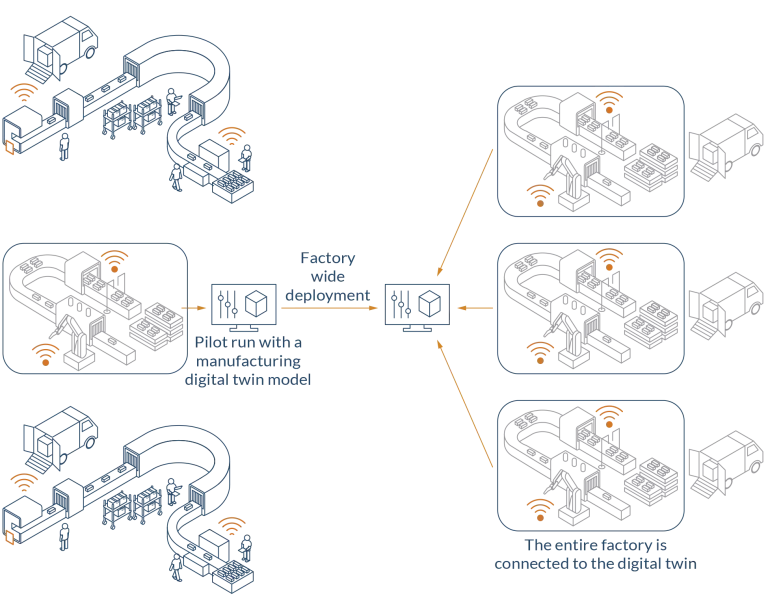

However, implementing a virtual twin requires, amongst other things, a deep understanding of the organization's need, careful planning and the validation of a pilot before expanding it.

So, how does one get started? And how does one achieve successful deployment?

Discover why companies around the world choose 3DEXPERIENCE on the cloud for virtual twin challenges

Simulation ensures that everything will function correctly prior to physical installation. It also enhances our service offering because we can propose larger and more complex installations

CenterLine Windsor Limited

CenterLine (Windsor) Limited needed to improve its robotics manufacturing processes methodology by implementing standard, collaborative single-source-of-truth technology to provide its customers with on-time, on-budget and efficient solutions.

4 Steps to successful Virtual Twin Experience realization

A Virtual Twin Experience consists of four discrete components: collaboration, modeling, optimization and performance.

Collaboration is the process by which the different stakeholders in any organization gather to work out the needs, wants and goals of the overall project by leveraging lean principles.

Modeling is the starting point for digitalization. It is the rendering of physical systems (and often humans, too) to create an accurate representation of machines, processes and workflows. Accuracy here is essential, and it must be maintained throughout the life of the project.

Optimization is the payoff from the Virtual Twin Experience, the process where changes are tested, tried virtually and tested again to reduce production bottlenecks and improve efficiency. This is where planning changes become true “what if” experimentation, iterating many changes in real time, from equipment cycles to worker time and motion study.

Performance is the ultimate goal of the actual implementation of the new processes and procedures worked out in the virtual factory. With a successful Virtual Twin Experience, production changes are swift, trouble-free and downtime is minimized. Sensor-equipped equipment then feeds real-time data back to the twin to confirm outcomes and establish a new baseline for the next series of experiments and improvements.

Beyond Digital Twin

Small and medium-sized manufacturers enjoy big-enterprise benefits and ROI with Virtual Twin Experience on the cloud.

Manufacturing Virtual Twins: The Keys to Success

Deploying Virtual Twins is more than just installing software. Discover in this webinar what manufacturing leaders should consider.

With Outcome-based engagement, we create your Virtual Twin

Dassault Systemes creates the Virtual Twin Experience for you when you are limited in time, human resources or it is simply not your primary competence. Get access to our latest webinar to know more about it! We Do It For You!

Get started with Virtual Twin Experience on the Cloud

Ready to be convinced?

See how Virtual Twin Experience on the cloud can transform your business.