AI-Guided Part Procurement Savings

Realize Significant Product Part Savings by Combining Artificial Intelligence and 3D Similarity Technologies

The Growing Product Parts Catalog

Reorganizations, mergers, global projects, personalization and innovation are all opportunities to add product parts to the catalog, thus increasing costs to design, test, source, manufacture, and store the parts. In addition, data silos and lack of communication between Engineering and Procurement functions can lead to poor management of expenditures. Furthermore, due to global disruptions, manufacturers report that suppliers are less reliable/predictable while costs are rising, transportation and deliveries are delayed, and factory capacity is reduced. Supply chain problems can drain revenue, but enhancing collaboration between Engineering and Procurement can help companies anticipate and mitigate these risks.

Better Manage Procurement Expenditures

According to Deloitte’s 2023 Global Chief Procurement Officer Survey, driving operational efficiency is at the top of enterprise priorities. Leading strategies to deliver the most value include: increasing supplier collaboration; enhancing data management; and renegotiating with existing suppliers. NETVIBES solutions help you do just that.

Data science optimizes a company’s procurement strategy and identifies major potential savings. Thanks to unique artificial intelligence-driven and 3D CAD Similarity technologies, industry leaders are cross-linking Engineering and Procurement data (ERP, PLM, Quality Management systems and other data sources) to quickly reveal similar or identical parts purchased with different reference numbers, suppliers and prices. Information is accessible through a seamless user interface for efficient sourcing and purchasing of the right parts from the right supplier at the right price and time.

From the design phase to sourcing and standardization management to AI-guided component search all the way through supplier negotiations, NETVIBES solutions on the collaborative 3DEXPERIENCE® platform decrease complexities and costs, minimizing compromises between program margin and time-to-market while ensuring quality. Turn your sourcing process into a strategic advantage with data-driven collaborative sourcing for dramatic savings.

NETVIBES Product Part Procurement Key Benefits

Lower Procurement Costs by 5-15%

Armed with data, better negotiate prices, consolidate suppliers and minimize stock

Increase Operational Efficiency by 10-30%

Improve collaboration between Engineering and Procurement with a cost-oriented mindset

Reduce Design Cycle Times by 30-70%

Make better informed decisions to reuse, purchase or make parts

Decrease Variants by 20-50%

Reduce complexity and time-to-market by increasing part reuse and streamlining the supply chain

Generate Savings & Protect Margin

Meet Louise, a component manager. Equipped with NETVIBES data science solutions, she’s able to generate part procurement savings and protect her company margin.

- Anticipate raw material price volatility impacts on vehicle cost

- Optimize procurement strategies with real-time insights

- Identify cost-saving alternative parts

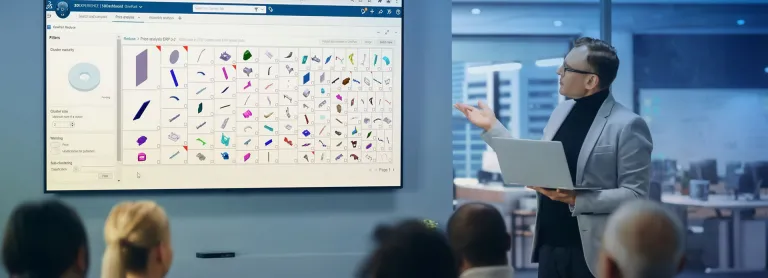

Key Capabilities of Product Part Procurement

Watch as engineers, suppliers and Procurement professionals collaborate around the virtual twin to decrease the complexity and cost of compromises between program margin and time-to-market. You’ll see how they’re able to identify negotiation opportunities and ultimately find the best parts that minimize risks and carbon footprint while realizing continuous sourcing improvement.

Customer Case Studies

Learn how leading companies are using NETVIBES data science solutions to better manage the sourcing and standardization of their product parts.

Start Your Journey

The world of Product Part Procurement is changing. Discover how to stay a step ahead with NETVIBES.

Product Part Procurement FAQs

Also Discover

Learn What NETVIBES Can Do for You

Speak with a NETVIBES expert to learn how our solutions enable people at all levels of the enterprise to make better, more informed business decisions.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right NETVIBES training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering