Quality Inspection

Improve Inspection and Quality Control Processes with Augmented Reality

Display Digital Instructions Directly in the Work Environment

DELMIA Augmented Experience for Quality Inspection guides the operator through the inspection process with digital instructions contextualized in the work environment allowing the identification, qualification, and reporting of non-conformities efficiently. Using augmented reality significantly improves the accuracy and speed of quality control and inspection processes. Because technicians can access real-time information, they make fewer mistakes, make more informed decisions, and quickly resolve problems.

Whether manual or automated, factory quality control procedures require the highest reliability and accuracy. The current inspection and quality control methods in manufacturing production or maintenance are long, tedious, and lack traceability. As a result, they can generate risks of errors and additional costs when non-conformities are not detected or identified too late in the inspection process.

DELMIA Augmented Experience revolutionizes these processes with faster and more reliable inspection and control operations assisted by augmented reality. By amplifying the quality process, users can reduce the risk of errors in defect location or interpretation by up to 90% and cut inspection time by up to 40%.

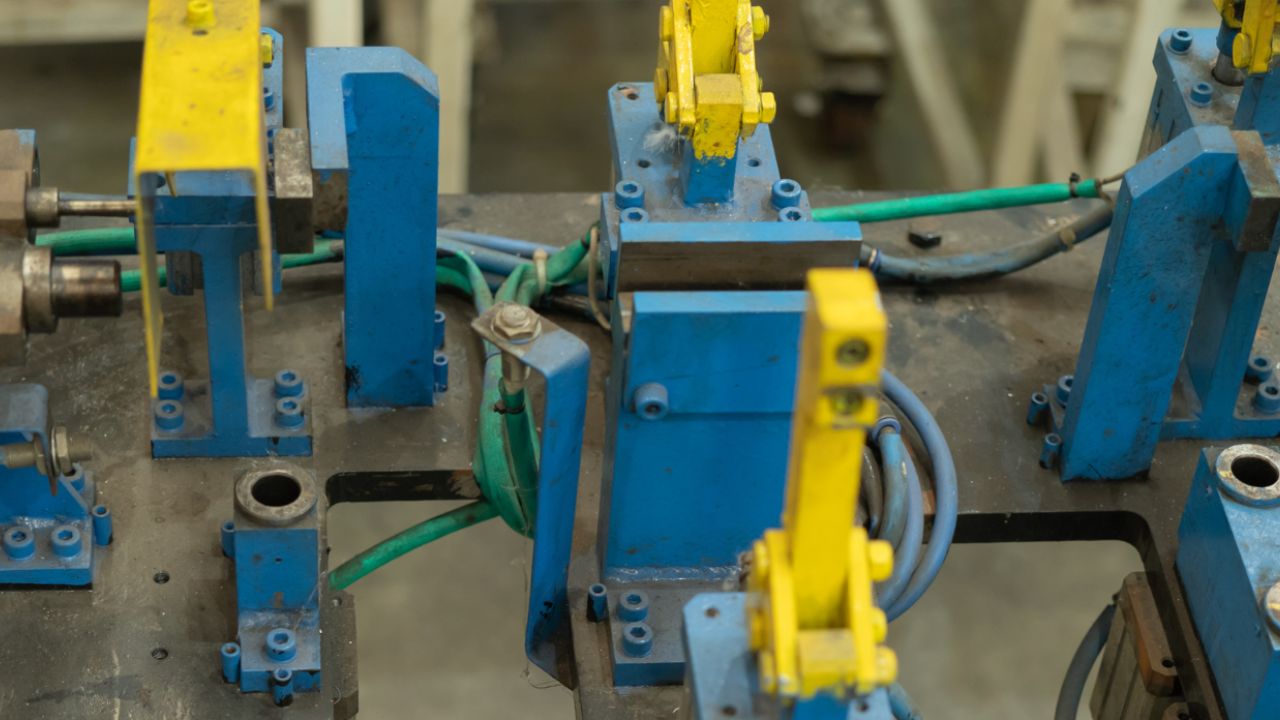

- Quality Control in a Production Context

- Incoming Inspection of Equipment from Supplier

- Assistance to NDT Control

Reliability. Therefore the ability to accurately identifying non-conformances at each stage of the manufacturing process is critical to ensure meeting quality standards and that defective products are not delivered to end customers. With DELMIA Augmented Experience for Quality Inspection, checkpoints and acceptance criteria are displayed on a screen or directly on the equipment to guide the operator and quickly identify non-conformities, and an inspection report is automatically generated. As a result, it decreases inspection and reporting times, it reduces scrapped parts and late rework costs, and improves operations traceability.

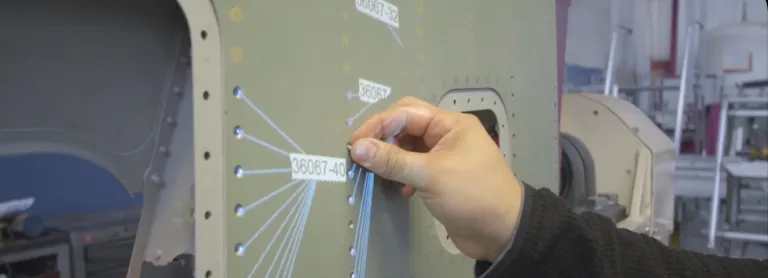

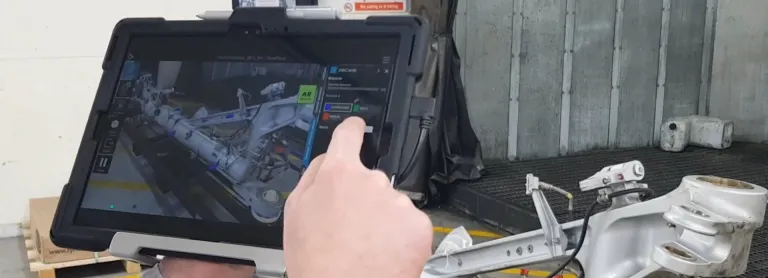

Identifying defective parts or sub-assemblies from suppliers is essential to establish and maintain strict quality standards and prevent defective parts or tooling from reaching assembly lines. However, the quality control process at reception can be very complex, time consuming, and lack precision. In addition, unexpected costs can occur due to late defect detection during production. DELMIA AR-based digital instructions provides the operator with detailed steps via a tablet or camera to confirm the compliance of incoming equipment or tools. This is done by comparing "as manufactured" with "as designed." Thus, users achieve improved quality and cost management based on efficient quality checks of parts received eliminating costly breakdowns and scraps.

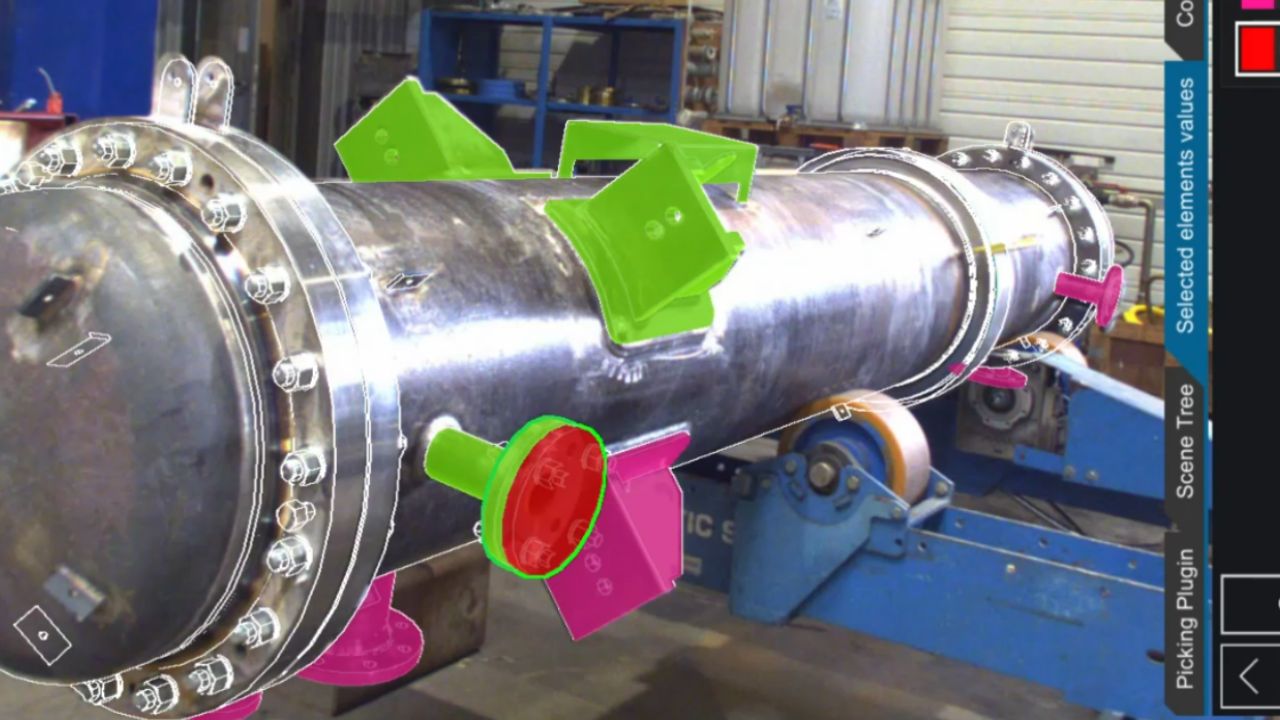

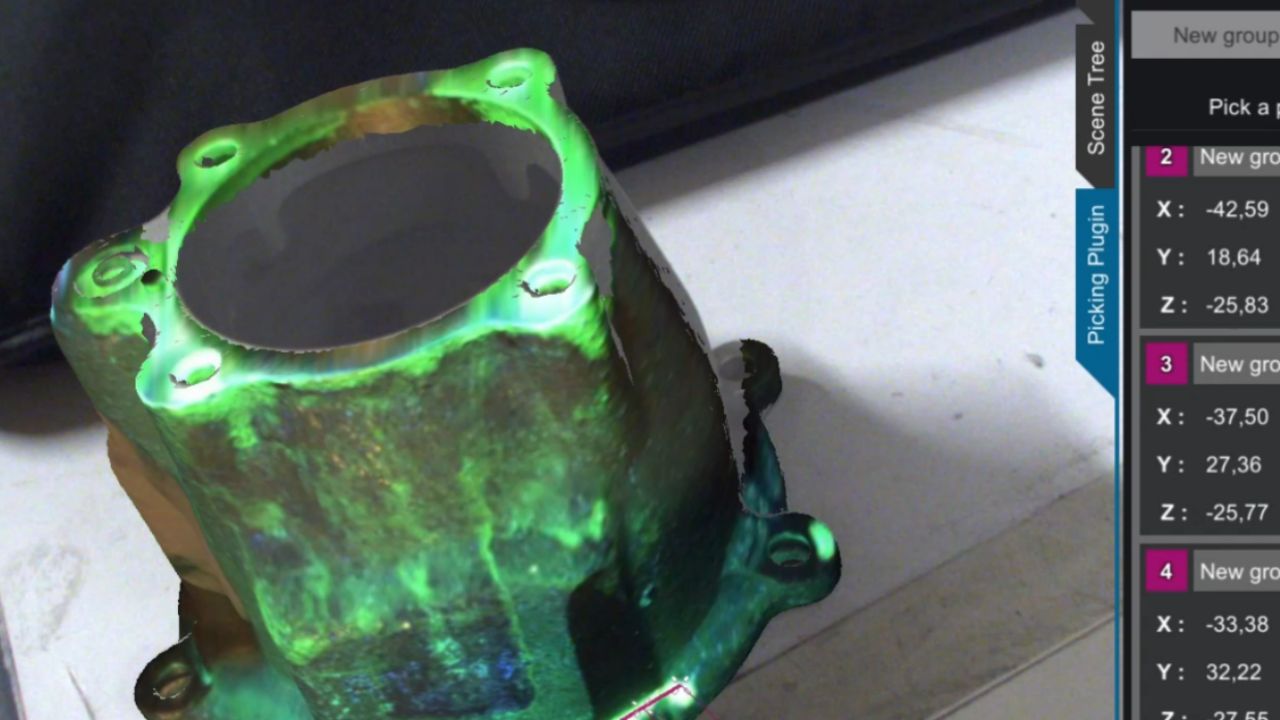

Non-destructive testing (NDT) ensures the quality and safety of products without damaging them, a crucial step because the slightest error can strongly impact performance costs. However, the capacity to easily visualize defects identified after the UV inspection and the information on their location of defects for the repair team is still too limited. DELMIA Augmented Experience compares the designed part to the built part by displaying the 3D model on the inspected part and identifying defects as "pick points." The defects are then mapped and located directly on the 3D model of the inspected part, and can then be efficiently displayed to the repair teams in another work environment.

FAQ about Quality Inspection

Start Your Journey

The world of manufacturing & operations is changing. Discover how to stay a step ahead with DELMIA.

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering