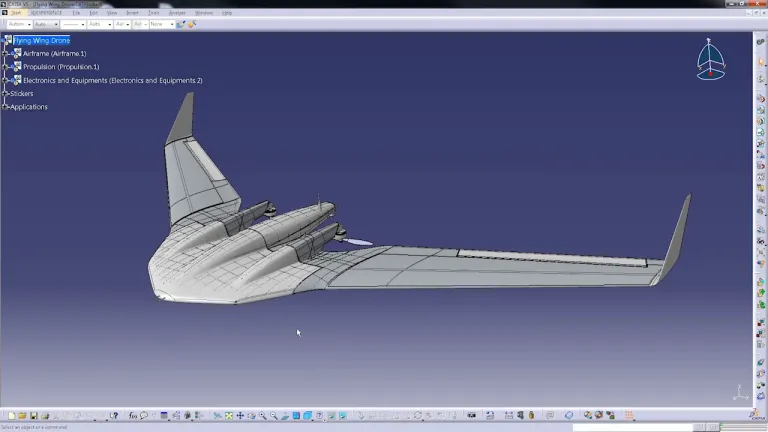

CATIA V5

Raggiungere l'eccellenza nella progettazione con CATIA V5, un software CAD (Computer-Aided Design)

Raggiungere l'eccellenza nella progettazione

CATIA V5, acronimo di Computer-Aided Three-dimensional Interactive Application V5, è una suite software ampiamente utilizzata per il CAD (Computer-Aided Design), il CAM (Computer-Aided Manufacturing), e il CAE (Computer-Aided Engineering). Si tratta di uno standard industriale per vari settori, tra cui quello automobilistico, aerospaziale, di macchine e impianti industriali e molto altro. Molte aziende utilizzano CATIA V5 per la progettazione e lo sviluppo di prodotti.

Vantaggi principali

- Integrato con le soluzioni PLM (Product Lifecycle Management), CATIA V5 consente alle aziende di gestire l'intero ciclo di vita dei prodotti, dal concept alla produzione.

- È composto da vari moduli, ciascuno personalizzato per specifiche attività di progettazione e ingegneria. Questi moduli includono Part Design, Assembly Design, Drafting, Surfacing e molti altri.

- Offre un'ampia gamma di strumenti e funzionalità per la creazione di progetti complessi e dettagliati.

- Si basa su funzionalità collaborative che migliorano la progettazione simultanea e consentono a più utenti di lavorare sullo stesso progetto contemporaneamente.

- Include funzionalità CAM che consentono la generazione di percorsi utensile per processi di lavorazione CNC.

- Fornisce strumenti per la simulazione e l'analisi, consentendo agli ingegneri di valutare le prestazioni, il comportamento e l'integrità strutturale dei prodotti.

Domini CATIA V5

| Progettazione meccanica | Progettazione di forme e stili |

| Fornisce prodotti per la modellazione intuitiva basata sulle specifiche per la progettazione di parti solide, ibride e in lamiera, la progettazione di assiemi e il disegno integrato. | CATIA V5 offre strumenti estremamente intuitivi per creare, convalidare e modificare facilmente qualsiasi tipo di superficie, da quelle a forma libera alle forme meccaniche. |

| Sintesi del prodotto | Ingegneria di apparecchiature e sistemi |

| Il set di soluzioni Knowledgeware trasforma i metodi di progettazione impliciti in conoscenza esplicita per progettare in modo ottimale, mentre le soluzioni DMU supportano revisioni e simulazioni DMU complesse per decisioni rapide ed efficienti in materia di ingegneria e processi. | Permette di integrare e scambiare informazioni di progettazione di prodotti elettrici, sistemi e strutture durante la definizione del prodotto. |

| Analisi | Machining |

| Ottimizza più rapidamente le prestazioni del prodotto con l'analisi integrata dei progetti in CATIA. | Grazie all'intero portfolio di prodotti e alla facilità d'uso dell'architettura V5 basata sulla conoscenza, CATIA V5 Machining supera tutte le suite di applicazioni per la produzione NC esistenti nel settore. |

| Infrastrutture | CAA-RADE |

| CATIA V5 offre una piattaforma completamente scalabile per la creazione collaborativa di prodotti e la gestione dei dati di prodotto. L'architettura innovativa di V5 offre un controllo avanzato della progettazione per lavori di ingegneria all'avanguardia. | Il portfolio di prodotti CAA-RADE fornisce la più completa gamma di strumenti, guide e API a supporto del processo di sviluppo, dalla definizione iniziale del prodotto al confezionamento finale. |

| Soluzioni di apprendimento basate sul Web | |

| CATIA V 5 Web-based Learning Solutions (WLS) è un sistema di apprendimento e supporto facile da usare. Fornisce tutte le informazioni e la formazione necessarie da un'unica fonte di dati per garantire la massima produttività della community di utenti. |

Opzione 1: Fai il passo successivo

Desideri ampliare le tue possibilità di sviluppo dei prodotti utilizzando la piattaforma 3DEXPERIENCE?

Ottieni una valutazione personalizzata di 3DEXPERIENCE CATIA. Questo strumento online di facile utilizzo calcola immediatamente una previsione dei risparmi e dei vantaggi in base al tuo input individuale.

Opzione 2: Lavora e collabora meglio con CATIA V5

Vuoi essere ancora più efficiente con CATIA V5 esplorando al contempo le funzionalità e i vantaggi offerti dalla piattaforma 3DEXPERIENCE?

Ottieni una valutazione personalizzata di CATIA V5. Questo strumento online di facile utilizzo calcola immediatamente una previsione dei risparmi in base al tuo input individuale.

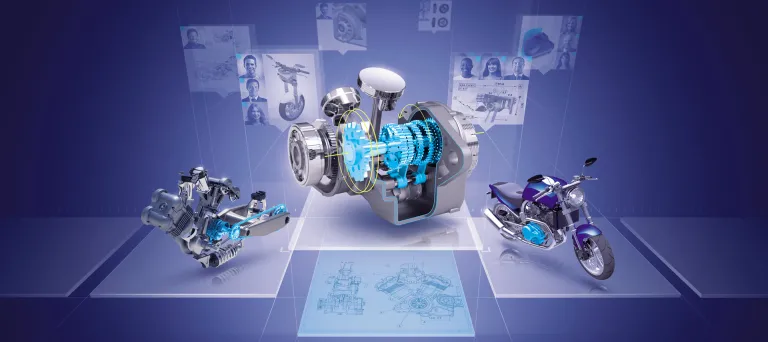

CATIA V5 Connected Engineering

Quando la collaborazione efficace si combina all'ingegneria di altissimo livello, nasce una combinazione vincente che rafforza l'esperienza dell'utente CATIA estendendo le prestazioni di CATIA V5 con l'aggiunta di nuove funzioni.

Gli utenti di CATIA V5 possono usufruire dei vantaggi della piattaforma 3DEXPERIENCE sul cloud e apprezzeranno la mobilità, la collaborazione e la sicurezza che offre.

MODSIM per gli utenti CATIA V5

L'innovazione parte da una progettazione di qualità. Unificando gli strumenti di progettazione e simulazione, i team possono adottare un paradigma shift-left durante il processo di progettazione a supporto di un approccio alla progettazione orientato alle prestazioni, che porterà a prodotti leader del mercato. In questo contesto, è possibile aggiungere applicazioni di simulazione agli strumenti CATIA V5 utilizzati per creare progetti complessi al fine di analizzarne le prestazioni e ottimizzarle. È disponibile un processo a 2 opzioni per sfruttare questo approccio integrato di MODellazione e SIMulazione, chiamato "MODSIM", al proprio ritmo.

Partecipa alle conversazioni nella community di utenti CATIA!

Domande frequenti su CAD e CAM

Scopri anche

Scopri cosa possono fare per te le soluzioni CATIA

Parla con un esperto CATIA per scoprire in che modo le nostre soluzioni consentono a organizzazioni di ogni dimensione di ottimizzare la collaborazione e promuovere un'innovazione sostenibile.

Per iniziare

Sono disponibili corsi e lezioni per studenti, accademici, professionisti e aziende. Trova il corso di formazione CATIA più adatto alle tue esigenze.

Ottieni assistenza

Trova informazioni sulle certificazioni software e hardware, scarica software e documentazione per gli utenti, contatta l'assistenza e scopri le offerte di servizi