Fabricated Metal & Plastic Products

Empowering Fabricated Metal & Plastic Products Manufacturers to Drive Sustainable Innovation and Maximize Efficiency, Quality, and Profitability reaching Manufacturing Excellence.

- Optimize Manufacturing Operation Efficiency

- Metal and Plastic Driven Innovation

- Workforce of the Future

- Embracing Sustainability

In today’s highly competitive environment, plastics and metal component manufacturers face increasing pressure to not only reduce costs but also enhance product quality. Customers are demanding greater variety and faster turnaround times, making it critical for manufacturers to shorten the time between product conception and delivery.

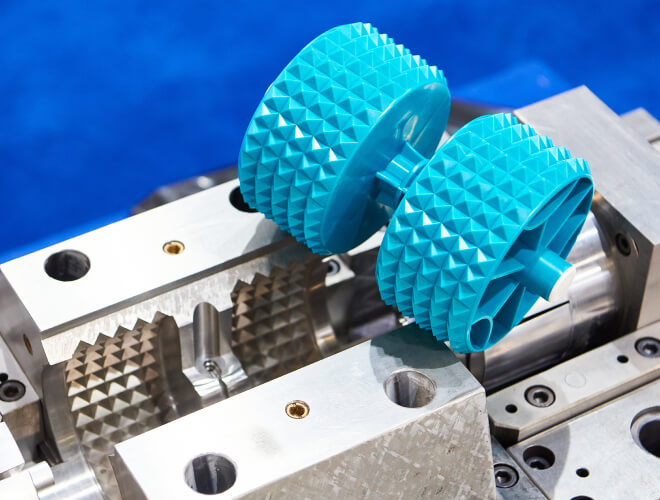

A key challenge in this industry is the balancing act between the mass production of large quantities at low cost and customized, smaller-batch orders, which often require complex shapes and on-demand production of components (such as screws, gears and hinges). This dual demand highlights the need for superior manufacturing capabilities that can scale and adapt efficiently.

What makes competition particularly fierce is that superior overall manufacturing capability — rather than product design, marketing or financial strength — has become the true secret weapon of leading competitors. Companies that succeed in this area gain a significant edge.

To stay ahead, many manufacturers are adopting new technologies and innovative approaches such as generative design, virtual testing and additive manufacturing (also known as 3D printing). These technologies enable them to keep pace with customer expectations and cost-effectively produce both metallic and plastic components.

Continuous improvements in manufacturing efficiency are vital not only for reducing costs but also for optimizing resource consumption and addressing environmental challenges. This contributes to business sustainability while enhancing competitiveness and profitability. Manufacturers that invest in improving their operational processes, minimizing waste and adopting sustainable practices will be better positioned to thrive in an evolving market.

High raw material costs and volatile supply chains continue to pressure metal and plastic product manufacturers. Geopolitical conflicts and challenging economic conditions have heightened the need for resilience across the value chain. To stay competitive, manufacturers must find ways to do more with less, extend the lifespan of machinery and innovate throughout their processes.

In response to these pressures, R&D efforts are increasingly focused on materials innovation as the industry shifts away from traditional raw materials and plastics to more sustainable alternatives. These include new compounds and alloys that are less resource-intensive and cause less environmental damage. At the same time, manufacturers are seeking ways to improve plastic and steel scrap recovery and increase recycling rates, contributing to sustainability goals.

In this highly competitive market, innovation is essential to differentiate product offerings. Faster product development cycles are also crucial as competition pressures manufacturers to shorten the time from product idea to delivery. By adopting new engineering technologies such as generative design, virtual testing and multi-discipline engineering, manufacturers can accelerate innovation and reduce development lead time.

Moreover, to remain compliant and manage risks in this evolving landscape, manufacturers are turning to risk-based approaches to compliance. Tailoring compliance strategies to their unique operations, risk profile and the specific countries and products they serve helps manufacturers mitigate costs and better manage their risks.

The fabricated plastics and metal product industry faces a growing challenge with an aging workforce. As baby boomers retire, they leave behind decades of experience and deep institutional knowledge, creating a significant skills gap. Younger generations often lack the same industry-specific expertise, posing a risk to long-term growth and innovation.

In this sector, continuous innovation is crucial for maintaining a competitive edge. Success depends on leveraging the experience and skills of the workforce to develop new materials, improve product durability and enhance manufacturing efficiency.

Retaining and transferring critical knowledge through mentoring, training programs and collaboration between senior and junior employees can help bridge the gap. Companies that prioritize knowledge capitalization and upskilling their workforce are better positioned to lead in product innovation. This not only helps improve operational efficiency but also supports sustainable growth in a rapidly evolving industry landscape.

By taking proactive steps to preserve and transfer expertise, companies will stay ahead of the competition, innovate more effectively and achieve long term success.

One of the biggest challenges facing metal and plastics product manufacturers is raw materials cost volatility. Geopolitical conflicts, economic instability, and other global factors contribute to severe disruptions, driving unpredictable price fluctuations. Experts project that raw materials will remain volatile over the coming decades, creating uncertainty for manufacturers who depend heavily on consistent supply chains.

Additionally, the world’s consumption of raw materials is expected to nearly double by 2060, which will place twice the pressure on the environment compared to today (OECD). This increases the urgency for manufacturers to adopt more sustainable practices to ensure the long-term availability of resources and to mitigate environmental impacts.

To address these challenges, manufacturers are increasingly embracing sustainability and circular economy initiatives.

These strategies are focused on:

- Sourcing and consuming raw materials responsibly

- Reducing waste throughout the production process

- Extending the lifespan of components

- Recycling and remanufacturing parts and materials

These efforts align with a global push towards responsible consumption and more sustainable manufacturing practices. By integrating these initiatives, manufacturers can help minimize resource depletion, reduce their carbon footprint, and produce components responsibly throughout the entire product development lifecycle.

By prioritizing sustainable manufacturing and supporting the circular economy, metal and plastics product manufacturers can remain credible suppliers in an increasingly eco-conscious market, securing both their competitiveness and commitment to responsible consumption.

Our Customers

Explore Our Solutions

FAQ

Manufacturing metal products involves designing, selecting materials, forming, cutting, assembling, and finishing. Techniques like casting, forging, machining, and welding shape the metal, while quality control ensures durability and performance.

Key challenges include raw material cost volatility, supply chain disruptions, environmental pressures, and the need to balance large-scale production with customized, small-batch orders.

They can adopt sustainable practices by sourcing materials responsibly, reducing waste, recycling, and extending product life through remanufacturing. Utilizing a circular economy approach also helps minimize environmental impact.

Fabricated metal and plastic manufacturers can enhance efficiency and sustainability by streamlining operations through lean manufacturing, which minimizes waste and conserves energy. Virtual twin technology allows companies to create digital replicas of production processes, enabling real-time simulations that optimize resource use and improve productivity. Choosing sustainable materials reduces environmental impact by focusing on eco-friendly sourcing. Advanced manufacturing technologies, such as 3D printing and automation, enable faster production while reducing waste. Additionally, recycling and remanufacturing efforts extend the lifecycle of materials, lowering dependence on new raw resources and further supporting sustainable practices.