Warehouse Modeling & Simulation

The complexity of warehouse operations is increasing, and leaders need both macro and granular visibility to manage increased responsibilities while improving profit margin.

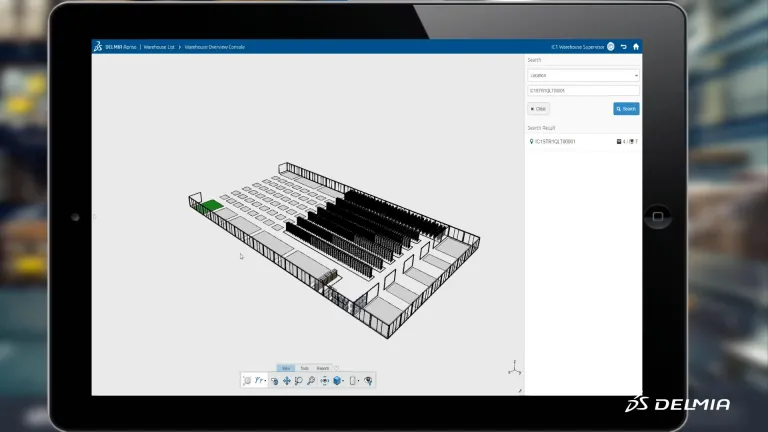

A virtual twin model of your warehouse gives you and your teams a single source of truth by simulating your physical systems (and often humans too), to represent equipment, robots, processes, and workflows accurately.

Modeling & Simulation in action

- Warehouse Modeling

- Simulate Workflow

Warehouse Modeling

Experience the power of model based design capabilities in a 3D environment to optimize uninterrupted movement of materials, people and traffic with no cross-flow clashes. Ensure lean design of warehouse while considering maximum space allocated to operational storage and stock processing purposes. Introduce and validate the use of automation elements like Robots, Cobots, AGVs, battery charging stations, etc. to build flexibility into the warehouse operation.

Simulate Workflow

Simulate your factory flows and analyze throughputs, identify bottlenecks and optimize your warehouse's performance. With customizable product routing rules, buffer capacities, and transfer time distributions, you can validate the behavior of workers, material handlers, workstations, lines, or even your entire warehouse. From simple to complex flows, get an early validation of your manufacturing process plans.

Resources

Contact our sales team

Are you ready to take the next step in your Warehouse of the Future journey? We can help! Fill in the form to have a Dassault Systèmes Logistics expert contact you. Include questions and topics you would like to discuss to tailor the call to your needs.

Next: 02 Planning and Optimization

Let your planners, supervisors and managers collaborate with decision-making

support on a virtual twin planning and optimization process.