Future of Metals & Steel Manufacturing

Optimizing steel, aluminum & copper production with end-to-end solutions that support efficiency and decarbonization in metals manufacturing

How Does the Future of Metals & Steel Manufacturing Look Like?

Decarbonization in metals means cutting CO₂ emissions across every stage, from ore extraction to rolling, long reliant on fossil fuels. The industry, spanning steel, aluminum, and copper, now faces mounting pressure to adopt circular economy principles.

Solutions like green hydrogen, green metals, and eco-friendly technologies are reshaping production.

Steel, central to this shift, is a major contributor: in 2020, the World Steel Association reported 1,860 million tons produced, accounting for 7–9% of global CO₂ emissions. To reach zero carbon, manufacturers must accelerate renewable energy use, resource efficiency, and circular practices.

Metals Manufacturing Trends 2026

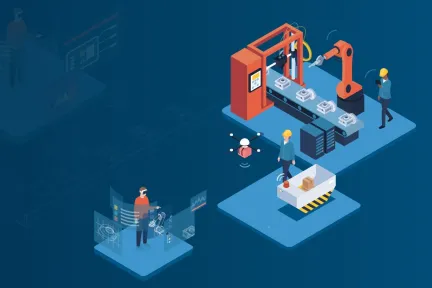

The metals industry faces rising costs and supply chain disruptions from new U.S. tariffs on imported metals, adding to global pressures like climate change and geopolitical instability. To stay competitive, manufacturers must move beyond reactive strategies and embrace digitalization. Solutions like DELMIA, powered by virtual twins, AI, and advanced analytics, enable real-time visibility, predictive planning, and smarter production.

- IoT, AI, and Data Analytics

- Sustainable Production Methods

IoT, AI, and Data Analytics

Metals manufacturers are increasingly adopting innovative technologies and processes for greater efficiency and sustainability. A key trend is the integration of Industry 4.0 / 5.0 solutions like IoT, AI, and data analytics, which enable real-time monitoring, predictive maintenance, and process optimization.

Smart and sustainable metal factories using these technologies can significantly reduce downtime and enhance production efficiency.

Sustainable Production Methods

By accelerating digital transformation and adopting sustainable practices, metals companies can build resilience, reduce risks, and emerge stronger in an uncertain trade landscape.

Among these practices, metal additive manufacturing, or 3D printing, is transforming the industry by creating complex components with less material waste, reducing costs, and supporting sustainability efforts.

Advanced metal recycling techniques are also emerging, allowing for the recovery and reuse of metals without sacrificing quality, thereby promoting circular economy initiatives

Pathways to Industrial Decarbonization in Metals

Digitalization, AI & Traceability

Virtual twins, real-time emissions dashboards, lifecycle analysis, and digital traceability enable compliance, transparency, and informed decision-making. They also give manufacturers a competitive edge in green procurement.

Fuel Switching & Renewable Integration

Electric arc furnaces (EAFs), when powered by renewables, offer a cleaner path than traditional blast furnaces. Meanwhile, green hydrogen is being piloted at industrial scale for direct reduced iron (DRI) processes.

Carbon Capture, Utilization & Storage

For processes where emissions are unavoidable, CCUS is the lifeline. Capturing CO₂ at the source and storing or repurposing it—into building materials or industrial inputs—represents an emerging pillar in net-zero roadmaps.

Energy Efficiency & Process Optimization

Improving energy intensity per ton of output remains the quickest ROI decarbonization move. Technologies such as AI-driven process control, digital twins, and advanced predictive maintenance can reduce energy waste, optimize furnace cycles, and eliminate downtime without the need for complete overhauls.

Circular Economy & Scrap Utilization

Recycled metals significantly reduce emissions: secondary aluminum uses up to 95% less energy than primary production. By enhancing scrap recovery systems and designing for recyclability, manufacturers can shrink both footprint and cost.

Step into our 3D experience and see how the future of metals manufacturing is being redefined.

Explore a next-generation green metals and steel factory featuring an electric arc furnace that runs on recycled scrap—cutting carbon emissions and driving the circular economy.

These innovations extend beyond steel to aluminum and copper, promoting sustainability across the entire industry.

How to Make your Future Metals Plant Successful?

We have developed cutting-edge solutions and innovations to turn metals manufacturing green, enhancing efficiency, promoting sustainability, and optimizing resource allocation.

Enhancing Efficiency with Manufacturing Operations Management

Our DELMIA Manufacturing Operations Management (MOM) system, together with Master Production Scheduling and Detailed Scheduling, provides greater visibility and control over production processes, helping to reduce disruptions and improve performance across sites.

Crucially, MOM also supports metals decarbonization by reconciling greenhouse gas (GHG) emissions data with production activities, enabling more accurate reporting, monitoring, and decision-making.

Accelerating Decarbonization with Sales & Operations Planning

For steel, aluminum, or copper production, advancements in Sales & Operations Planning (S&OP) and forecasting tools can help align demand and supply, improve logistics, and manage inventory more effectively. These approaches also contribute to circular economy practices by encouraging reuse, waste reduction, and more sustainable operations.

Whether for greenfield projects, where digital twins enable net-zero plant design from the outset, or brownfield upgrades that require 3D scans, retrofit simulations, and optimized shutdown planning, companies can accelerate transformation while minimizing risks and emissions

Key Benefits of DELMIA Metals & Steel Solutions

Competitive Advantage

Implementing cutting-edge technologies like AI, IoT, and Virtual Twin positions metal manufacturers at the forefront of innovation, giving them a competitive edge in the market.

Enhanced Sustainability

Adopting virtual twin and green technologies helps reduce the carbon footprint of metal production, thus aligning with global sustainability goals and enhancing the company’s reputation.

Improved Operational Efficiency

Leveraging advanced planning and scheduling tools, metals manufacturers can significantly enhance operational efficiencies— resulting in reduced lead times, lower inventory levels, and cost savings.

DELMIA Metals and Steel Manufacturing Software

Shaping the Future of Metals and Steel FAQs

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering