Artificial Intelligence in Manufacturing & Supply Chain

Leverage the Power of AI-enabled Systems

What is AI in Manufacturing and Supply Chains?

Artificial Intelligence (AI) I in manufacturing and supply chains refers to the use of artificial intelligence technologies to optimize operations, improve efficiency, and enhance decision-making. It includes applications like predictive maintenance, demand forecasting, quality control, and supply chain automation, enabling businesses to reduce costs, minimize downtime, and adapt to dynamic market conditions.

Key Benefits of Using AI

Boost Efficiency

AI enhances operational efficiency by automating repetitive tasks, optimizing resource allocation, and streamlining workflows. This allows industries to reduce downtime and increase productivity.

Improve Product Quality

By leveraging predictive analytics and real-time monitoring, AI helps identify defects early and ensures consistent quality throughout production, leading to higher customer satisfaction.

Reduce Costs

AI minimizes waste, reduces operational errors, and optimizes energy use, resulting in significant cost savings for businesses.

Make Informed Decisions

AI processes vast amounts of data to provide actionable insights, enabling manufacturers to make data-driven decisions that positively impact their bottom line.

Scale and Adapt

AI systems are highly scalable, allowing businesses to adapt quickly to market changes, new technologies, and increased demand, ensuring long-term competitiveness.

Transforming Industries with AI in Manufacturing and Supply Chains

- AI in Supply Chain Planning and Scheduling

- AI Applications in Manufacturing

AI in Supply Chain Planning & Scheduling

In supply chain management, AI processes vast data sets to optimize resource allocation, enhance demand forecasting, and streamline scheduling. By integrating AI technologies, businesses can make agile, data-driven decisions, improve service levels, and efficiently manage inventory.

AI Application in Manufacturing

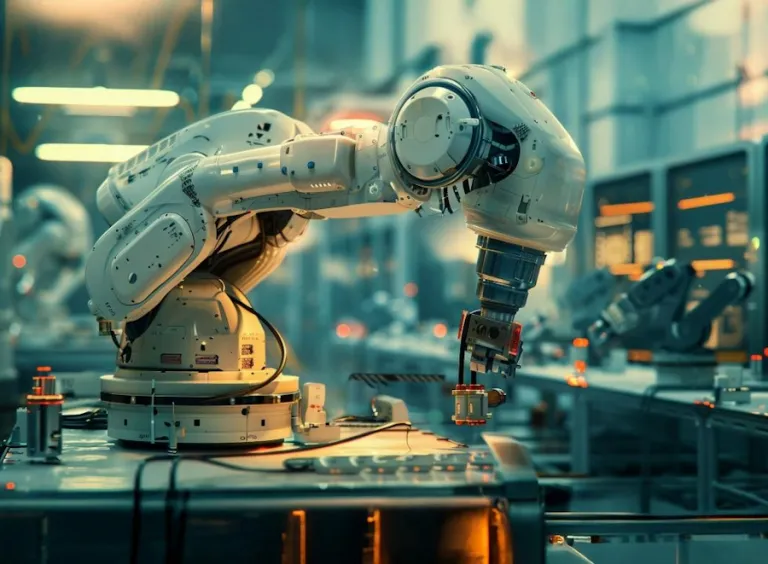

AI is revolutionizing manufacturing by enabling predictive maintenance through machine learning (ML). By analyzing historical and real-time equipment data, AI identifies patterns and predicts potential failures. This allows manufacturers to perform maintenance only when necessary, minimizing unexpected downtime and extending machinery lifespan.

Optimizing Industrial Operations in Many Areas with AI

Incorporating AI into industrial operations brings significant benefits:

Enhancing Manufacturing with AI and Augmented Reality

Augmented Reality (AR) overlays critical information like blueprints and real-time data to improve production, assembly, and quality processes. When combined with Artificial Intelligence (AI), AR systems can detect anomalies, alert operators, and adjust parameters in real time for optimal performance. AI-powered AR also uses machine learning to recognize objects and movements with precision, enhancing decision-making and efficiency in complex manufacturing environments.

What is an Example of AI being used by our Customers?

Wieland integrated AI into their business by adopting DELMIA Quintiq for strategic planning, addressing complex production needs. This solution enhances scheduling, capacity planning, and routing generation, providing transparency and optimizing production. Transitioning from spreadsheets to real-time planning, it allows scenario simulations for optimal decisions. The AI solution integrates with ERP and MES systems, supporting sustainable production by reducing energy use and considering personnel availability. This move boosts Wieland's competitiveness, meeting customer needs and sustainability goals efficiently.

Start Your Journey

The world of artificial intelligence in augmented reality is changing. Discover how to stay a step ahead with DELMIA.

FAQ about AI in Manufacturing and Supply Chain

Several industry sectors heavily utilize AI for manufacturing and global operations to improve efficiency and reduce costs:

- Automotive: AI is utilized to optimize supply chain and manufacturing operations by enabling real-time tracking of components throughout the production process and improving predictive analytics for supply chain disruptions, which enhances overall efficiency and reduces lead times.

- Aerospace and Defense: AI is being used in manufacturing and supply chain operations to enhance predictive analytics for procurement, streamline production processes, and improve supply chain visibility, ensuring timely delivery and operational readiness.

- Electronics & High Tech: AI is deployed to optimize production and quality control by utilizing predictive analytics and automating intricate testing processes to ensure high-performance outputs and reduce defect rates.

- Consumer Goods: AI supports automated manufacturing, streamlines inventory management, and predicts market trends.

- Retail: AI improves demand forecasting, enhances inventory management, and empowers optimized, sustainable logistics planning.

- Pharmaceutical and Life Sciences: In this sector, AI enhances drug discovery, speeds up clinical trials, and improves supply chain logistics through better demand forecasting and inventory management, ensuring timely availability of critical medicines.

- Food and Beverage: The industry uses AI to maintain quality standards, improve production scheduling, and optimize supply chains through real-time analytics, leading to reduced waste and enhanced freshness of products.

AI is crucial in the industry today because it significantly enhances efficiency, productivity, and decision-making processes. By integrating AI, industries can automate complex tasks, reduce errors, and improve quality through predictive analytics and real-time data monitoring. Moreover, AI-driven solutions facilitate the adaptability and optimization of operations, which ultimately lead to cost savings and improved competitiveness. As businesses face growing demands for faster, high-quality outputs, AI provides the necessary tools to meet these challenges effectively, setting new standards in performance and innovation.

Artificial Intelligence is a broad field of computer science focused on creating systems capable of performing tasks traditionally requiring human intelligence. These tasks include decision-making, speech recognition, and language translation. Machine Learning (ML), on the other hand, is a subset of AI that involves the development of algorithms and statistical models that allow computers to learn and make decisions based on data. While AI encompasses the overall concept of machines acting intelligently, ML specifically focuses on the methods and processes by which machines gain this intelligence through data-driven learning.

Artificial Intelligence (AI) is the simulation of human intelligence in machines, enabling them to think, learn, and perform tasks that typically require human intelligence. AI enables machines to perform tasks such as speech recognition, image processing, natural language understanding, and problem-solving. It encompasses subfields like machine learning, computer vision, and natural language processing.

While Augmented Reality (AR) technology seamlessly incorporates virtual elements in 3D within a real environment in real-time, its core principle revolves around digitally merging the virtual and real worlds for seamless integration. In this case, it goes beyond simply overlaying virtual information onto an image and instead integrates synthetic information into the actual environment.

In contrast, Virtual Reality (VR) technology completely transports a user into a computer-generated reality. This immersion is typically facilitated by hardware devices like VR goggles, virtual reality headsets, or enclosed spaces with video screens that occupy the user's entire field of view. VR provides an immersive experience within a 100% synthetic and digital environment.

Read more about what is augmented reality in the Manufacturing Industry and its benefits on our blog.

Generative AI in manufacturing and supply chain plays a pivotal role in transforming industry operations through enhanced efficiency and optimized processes. In manufacturing, it optimizes production processes, streamlining operations and fostering innovative production efficiencies.

For supply chains, generative AI enhances logistics by improving route planning and resource allocation, leading to cost savings and increased efficiency. Additionally, it empowers predictive analytics, facilitating informed decision-making by forecasting market trends and aligning supply with demand effectively.

AI is used in robotics to enhance capabilities by enabling robots to learn from their environments and adapt to different tasks. Through machine learning algorithms, robots can process large amounts of data to improve decision-making and problem-solving abilities. AI also facilitates autonomous navigation and precise object manipulation, making robots more efficient in complex and dynamic settings. These advancements allow for greater flexibility and functionality in industrial robotics, ultimately contributing to smarter and more versatile automated systems.

AI is used in production for predictive maintenance, quality control, process optimization, and automating repetitive tasks. It enhances decision-making with real-time data analysis, ensuring efficient and cost-effective operations.

AI improves efficiency by automating workflows, optimizing resource allocation, and reducing downtime. It enables real-time monitoring and predictive insights, helping manufacturers streamline processes and boost productivity.

AI will not fully replace manufacturing but will transform it by automating repetitive tasks and enhancing decision-making. Human expertise will remain essential for complex problem-solving, innovation, and strategic oversight.

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering