Innovate with Confidence through MODSIM

How MODeling & SIMulation Enable Mechanical Engineers to Prove Functional Performance and Feasibility

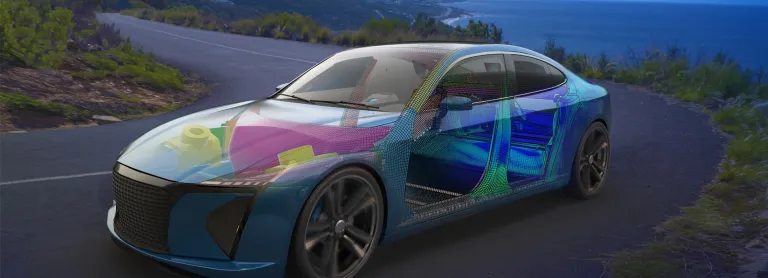

Product Optimization with MODSIM

Modeling and simulation play a pivotal role in performance-driven design by enabling engineers to create virtual representations of products and systems, simulate their behavior, analyze their performance and optimize it. We call “MODSIM” this integrated MODeling & SIMulation approach. Engineers, introducing systematic preliminary simulations at the earliest phase of product development, can make evidence of the functional performance across multiple domains. As they share the same data as the simulation analysts, this reduces the number of iterations and supports closer collaboration with them.

Furthermore, engineers explore design alternatives and trade-offs by quickly evaluating different design configurations and parameters. They can identify optimal solutions that strike the right balance between performance, cost, sustainability, circularity, manufacturability and other constraints. This iterative approach allows for continuous improvement and innovation, leading to superior products that outperform competitors in the market.

Moreover, engineers can develop sustainable processes because they anticipate and mitigate potential issues early in the design process. By identifying potential failure modes, optimizing performance characteristics throughout the entire product lifecycle, and systematically validating designs against real-world operating conditions, engineers can minimize the risk of unexpected failures or performance shortcomings once the product is deployed.

Develop the Best Design during the Concept Phase

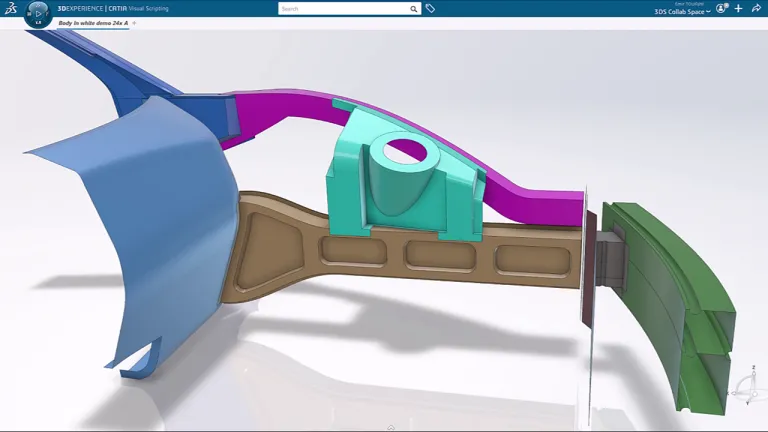

Extend Engineering process towards KPI driven Concept Engineering. Via an early collaborative concept process, Concept Engineers can automatically explore hundreds of innovative structure designs. Through MODSIM, they immediately secure evidence for excellent performance in safety, strength, ligthweighting and comfort before investing in details. Conveying high-quality designs and product knowledge dramatically speeds up manufacturing times.

Today, 3DEXPERIENCE CATIA "Concept Structure Engineering" integrates CATIA SFE CONCEPT technologies, widely adopted by major companies. Stiffened Structures, including Composites ones, can also be created, validated and quickly converged from shapes to fastening.

Performance Driven Design Through Generative Design

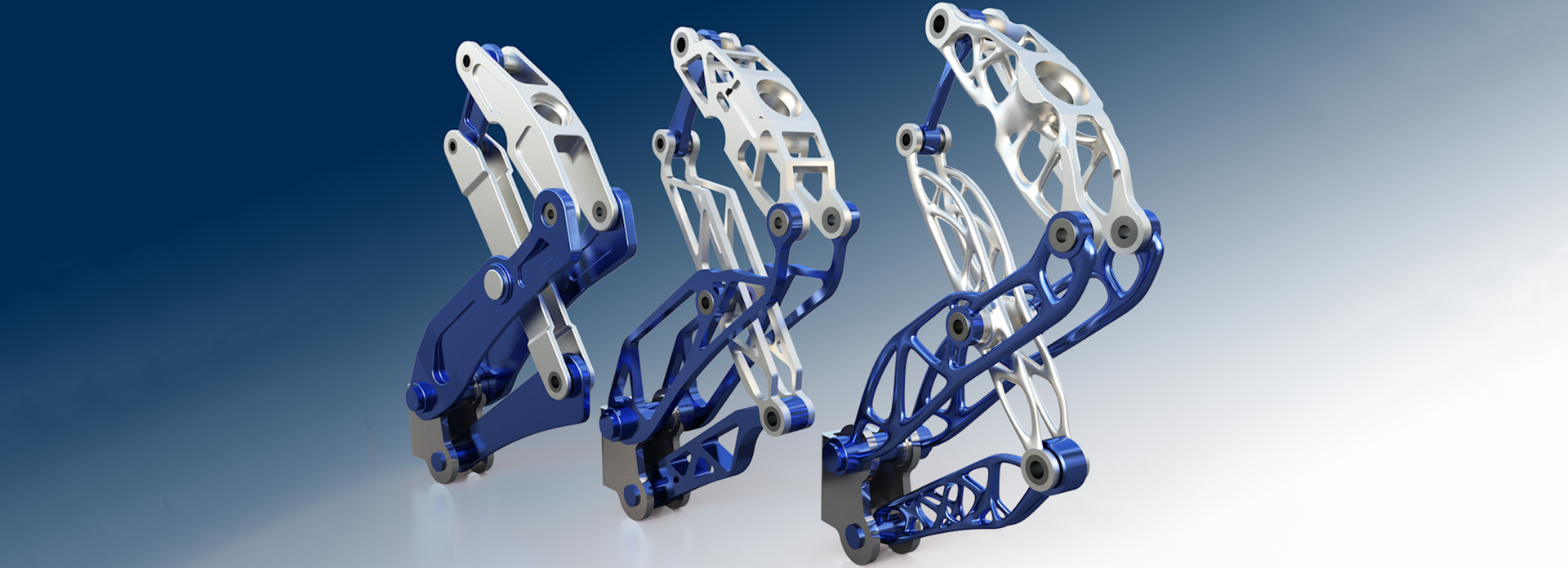

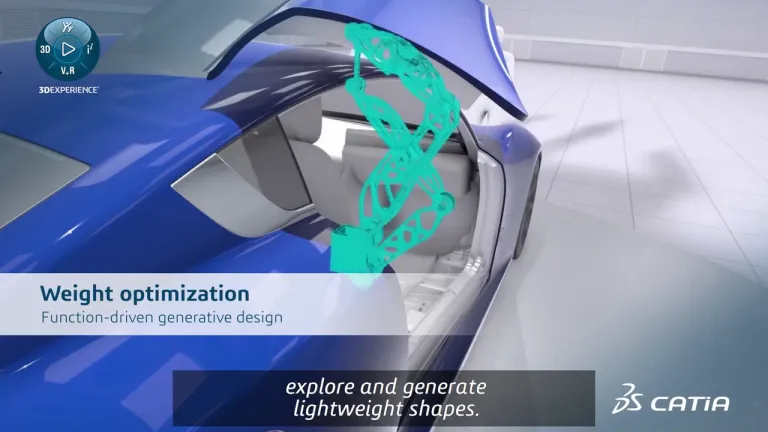

Optimize Engineering According to your Specifications. The generative approach allows a design engineer to innovate and stay focused on defining functional requirements by letting the system generate design alternatives. The simulation of these alternatives reduces the number of those required by analysts. This shortens the time to design & validate a complete system from months to hours.

By parallelizing trade-off studies, "Function Driven Generative Design" drives structural performance and reduces weight, for example, while "Flow Driven Generative Designer" do the same for fluids and "Structural Generative Designer" for thin parts.

Design for Manufacturing

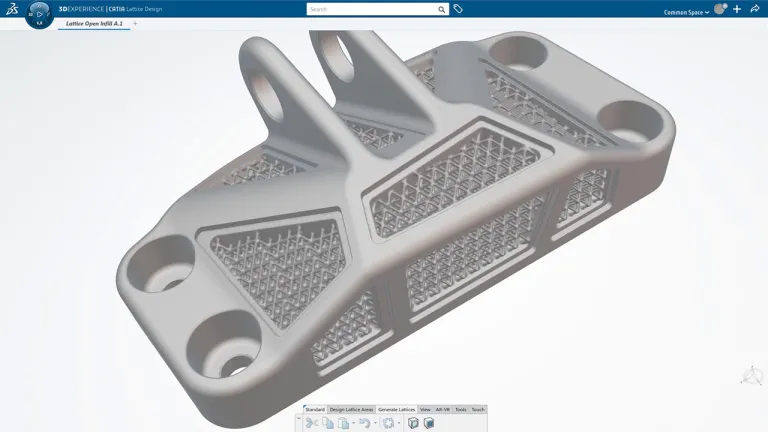

Account manufacturability for lattice design or other complex parts

MODSIM offers multi-discipline and multi-scale simulations. This allows engineers to simulate physical effects induced by different manufacturing processes, such as Stamping, additive manufacturing, composites, etc...

In particular, Stamping Die Engineers can simultaneously optimize the body design and simulate its formability.

Lattice structures are often created for high-performance parts, for example to maximize heat exchange or resist deformation. Conceptual and detailed 3D lattice modeling capabilities are seamlessly integrated with structural validation, and their output format tailored to 3D printers.

With robust CAE processes at the concept design phase, designers are realizing that what we are doing through optimization is lowering their costs, their weight and improving their performance, and it's not a trade-off. Value is going to go up because you spend less money on testing, and time to market has been shrunk because of this collaboration.

Start Your Journey

The world of Performance-drive Design with MODSIM is changing. Discover how to stay a step ahead with CATIA

Also Discover

Learn What CATIA Can Do for You

Speak with a CATIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right CATIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering