Performance-Driven Generative Design with MODSIM

Optimize Your Design with MODSIM (Modeling & Simulation)

Innovate and Validate Faster with MODSIM

In many industries, due to competitive pressure and customer demand, companies need to innovate and drastically reduce their time to market while maintaining cost and quality levels. Simultaneously, the need for Circularity and Sustainability for products and services has reached a turning point. Finally, with products becoming more complex, the faster you can validate your product and its manufacturability through simulation, the more time you’ll have for technical innovation.

What is MODSIM Software?

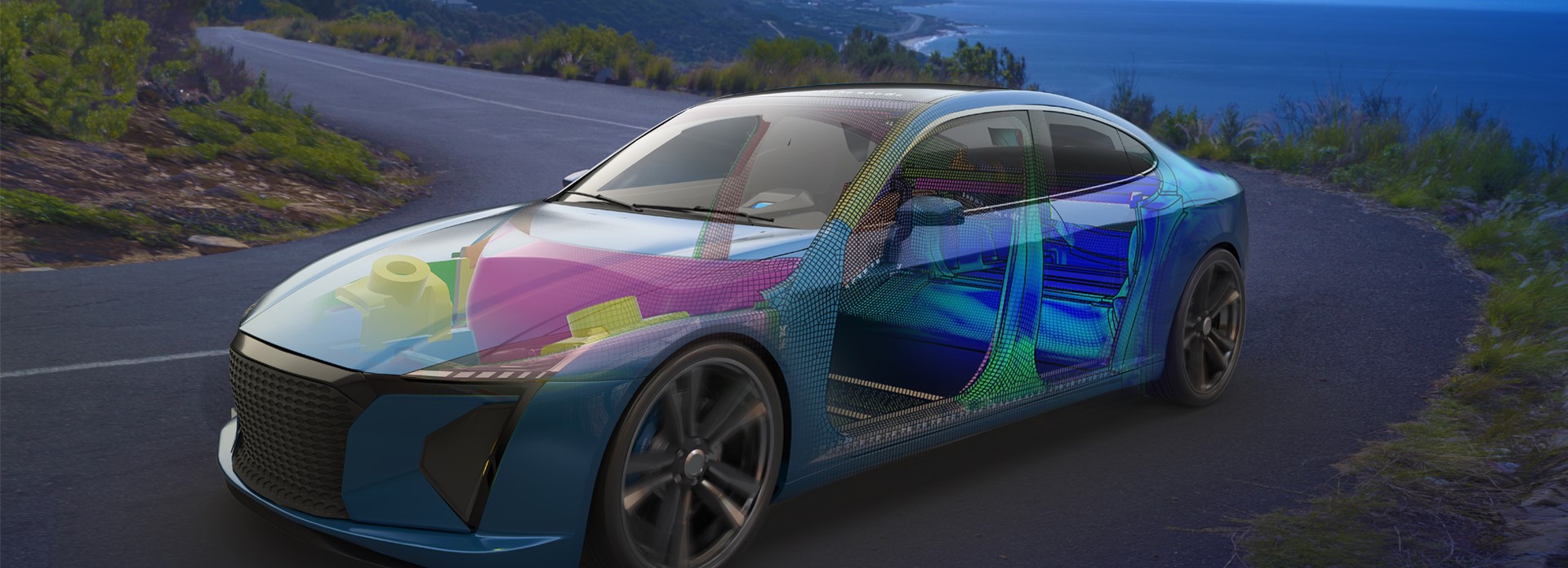

MODSIM is a product development approach that unifies MODeling and SIMulation on a common data model within a single user experience on the 3DEXPERIENCE platform.

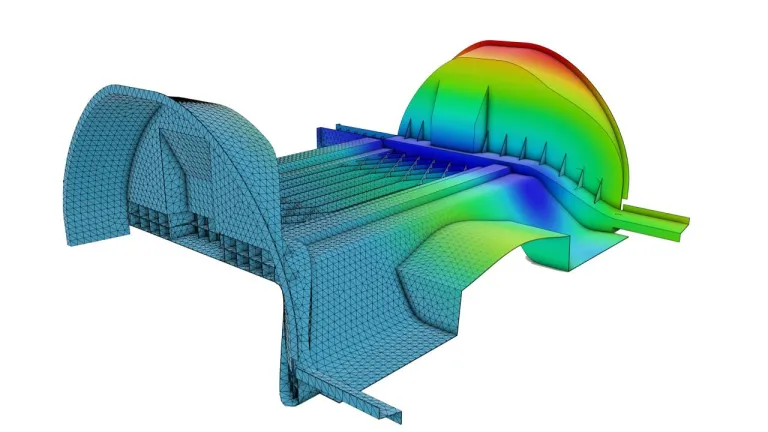

MODSIM enables a simulation-empowered shift-left strategy that pulls verification and validation upfront in the concept phase of the design. The design engineer can investigate multiple design options, visualize physical simulation variants and select those closest to the requirements specification.

What Benefits Can You Expect?

Reshape your product development. MODSIM brings a revolution to the productivity of engineers and product teams. Using simulation templates, engineers can consider sustainability, performance, manufacturability and all KPIs throughout the product lifecycle, even if they are not experts, decreasing the number of iterations with the simulation department.

Achieve sustainability targets: Across all industries, leading organizations are already democratizing and automating simulation processes. They demonstrate how it enables them to validate requirements from the start of design, while putting sustainability at the center of what they do.

Innovate with Confidence Through MODSIM

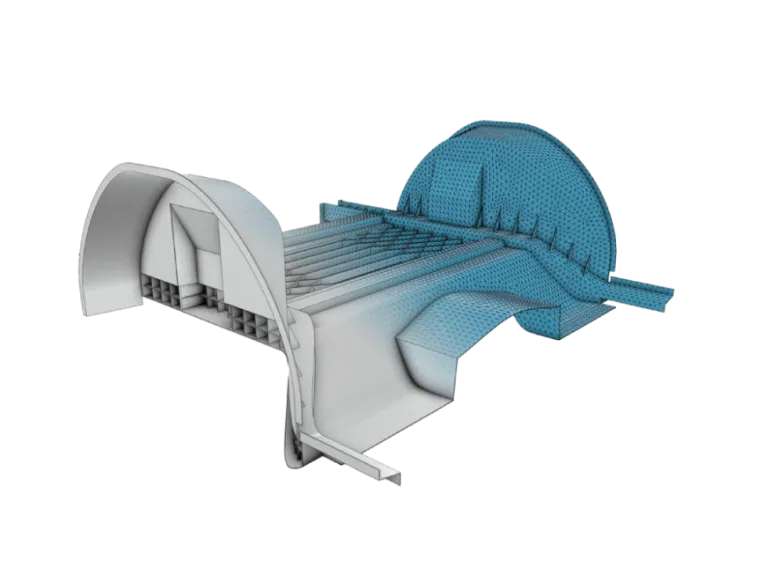

MODSIM enables mechanical engineers to accelerate functional performance and feasibility through a comprehensive set of engineering solutions. By integrating solutions such as Concept Engineering, Lightweight Engineering, and Lattice Design, MODSIM enables engineers to explore innovative designs.

Engineers can create virtual representations of products, simulate their behavior, and analyze their performance early in the development process. This approach reduces iterations and improves collaboration, leading to higher quality products. Multidisciplinary simulations within MODSIM ensure that designs meet all performance criteria.

What we need for designers is well-integrated tools. If they are in the same tools CATIA and SIMULIA – same function, same environment- they will use it. If we ensure this traceability, we give a proof that we assess the performance for the customer and that we can validate the vehicle.

Start Your Journey

The world of Performance-drive Design with MODSIM is changing. Discover how to stay a step ahead with CATIA

FAQ about Performance-Driven Generative Design with MODSIM

Also Discover

Learn What CATIA Can Do for You

Speak with a CATIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right CATIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering